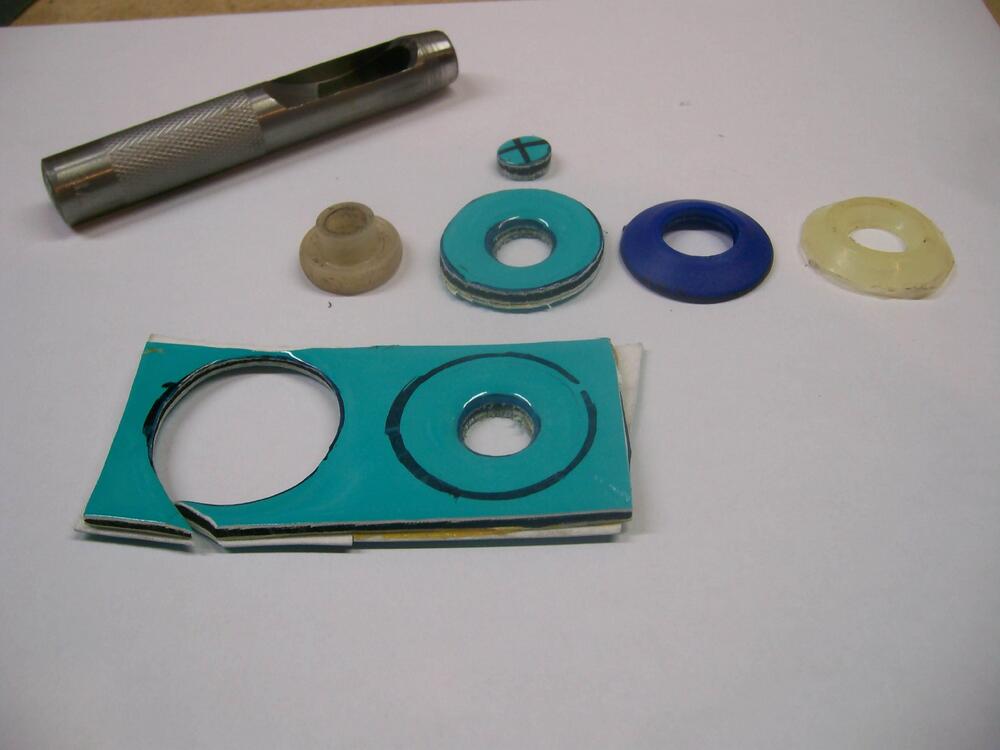

Near the end of my time in the garage today, I started to put the antenna on the car. I started by finding all the relevant parts from 240zrubberparts.com:

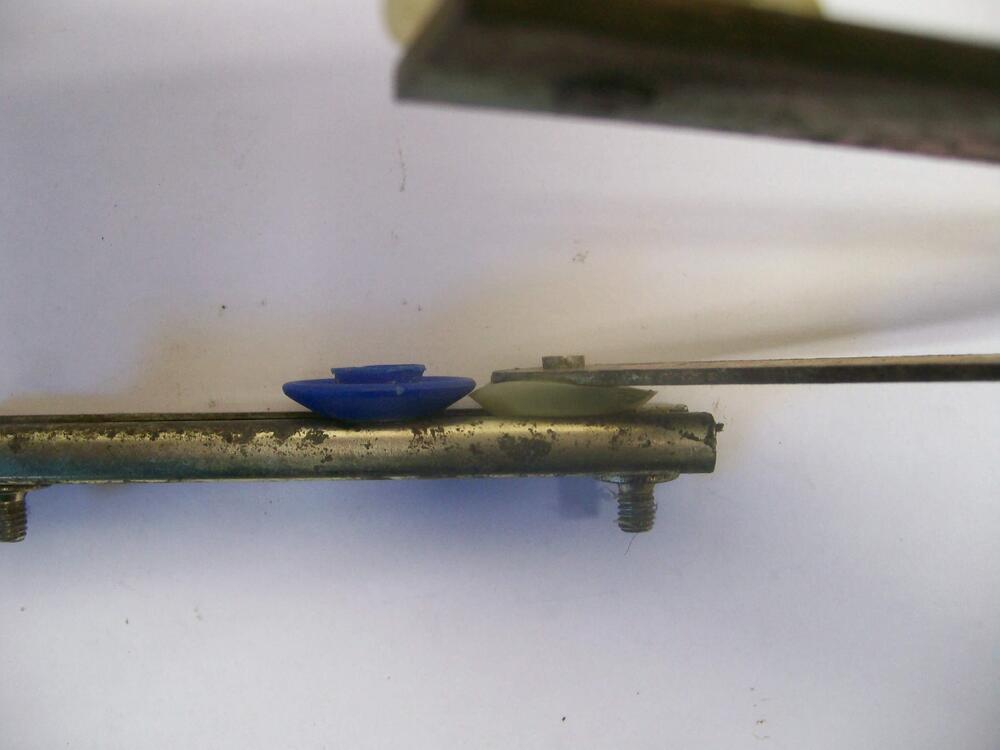

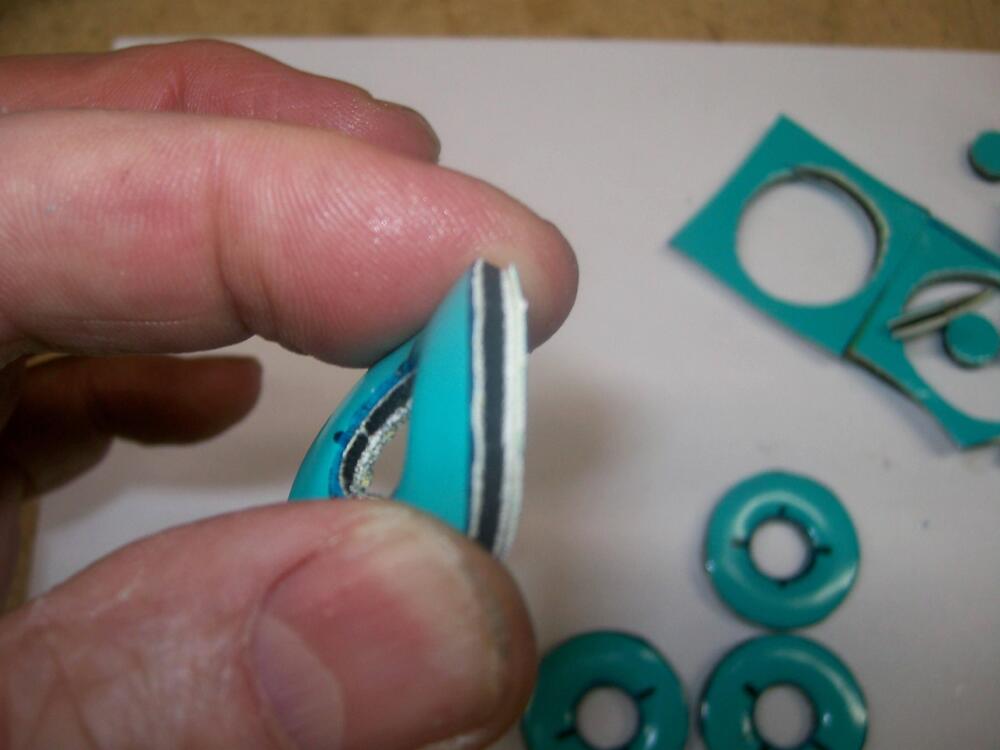

After some trial and error, I got things assembled, but I do not know where this seal (first pic of three) from the antenna mount kit goes. It kind of fits inside the top, plastic part of the ball, but kind of doesn't either.

It appears to have threads on the ID, but they don't match anything. Also, the ID is too large to make sense anywhere that I can see. I sent an email to Steve at 240zRubberParts to see if he knows. I ended up leaving it out for now.

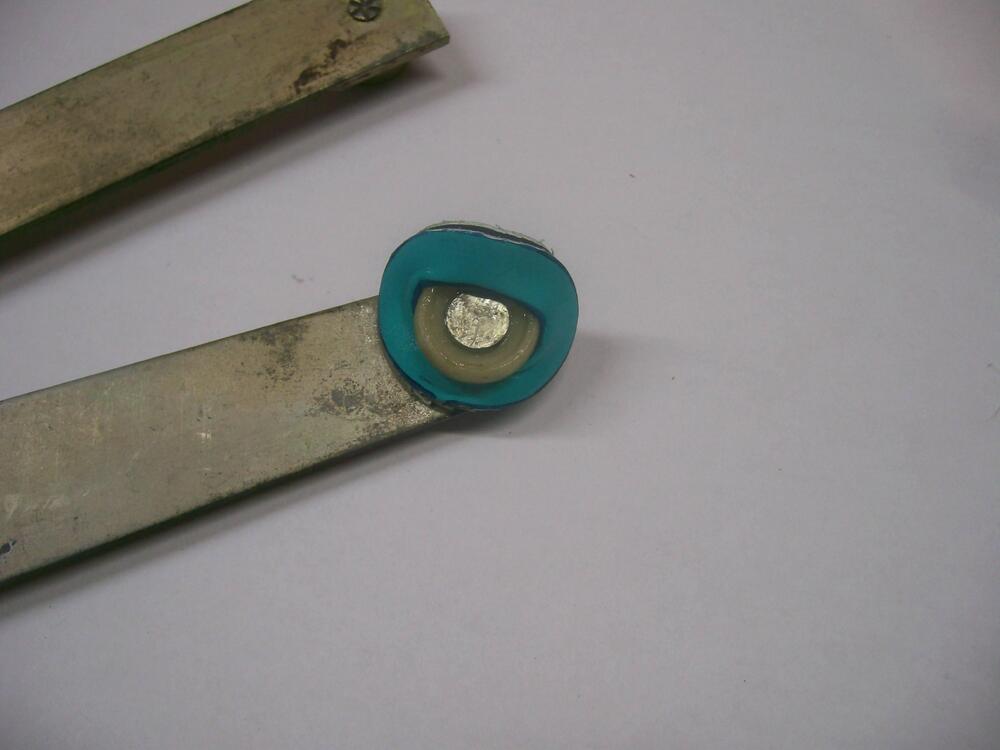

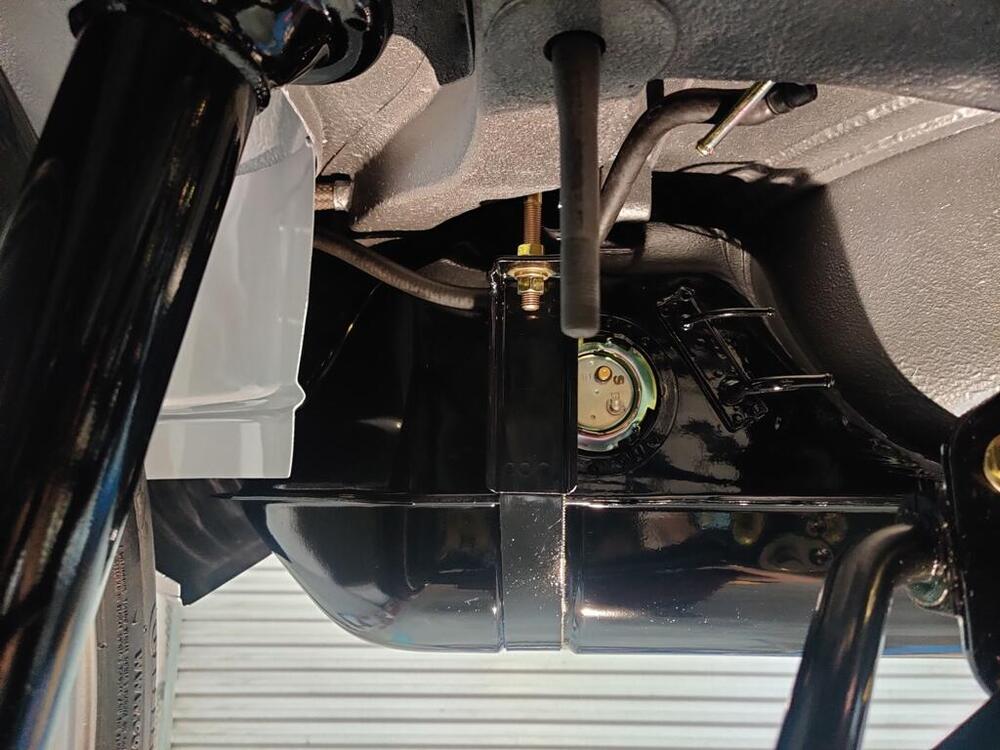

The antenna doesn't fit very well to be honest. Where the antenna goes through the body, it is very much an angle. As a result, the round metal concave/convex washer that seats on the grounding strap contacts the underside surface of the quarter panel before the nut on the outside is fully tightened. This causes the plate with the sharp points (other end of the grounding strap) to not seat properly on the underside surface of the quarter panel.

Unless I am missing something, I will likely take it apart again and do some grinding on the concave/convex washer to create clearance where it is hitting the body. That will allow the stack to tighten properly, and should allow the plate with the sharp points to fit properly (flat against the underside surface of the quarter panel for its full circumference).

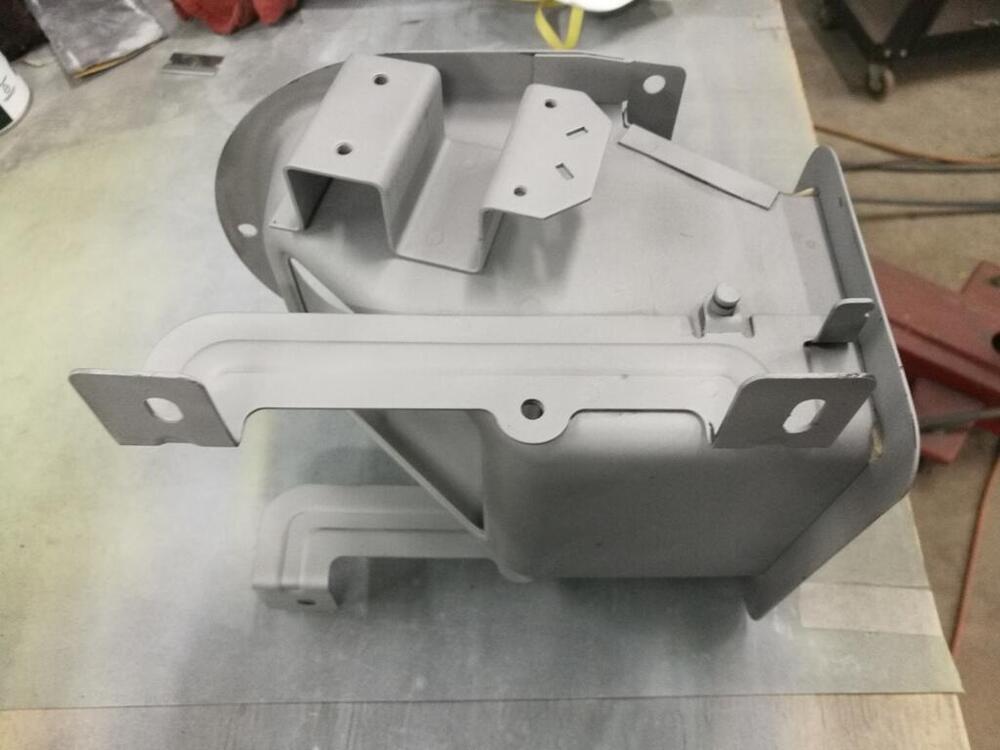

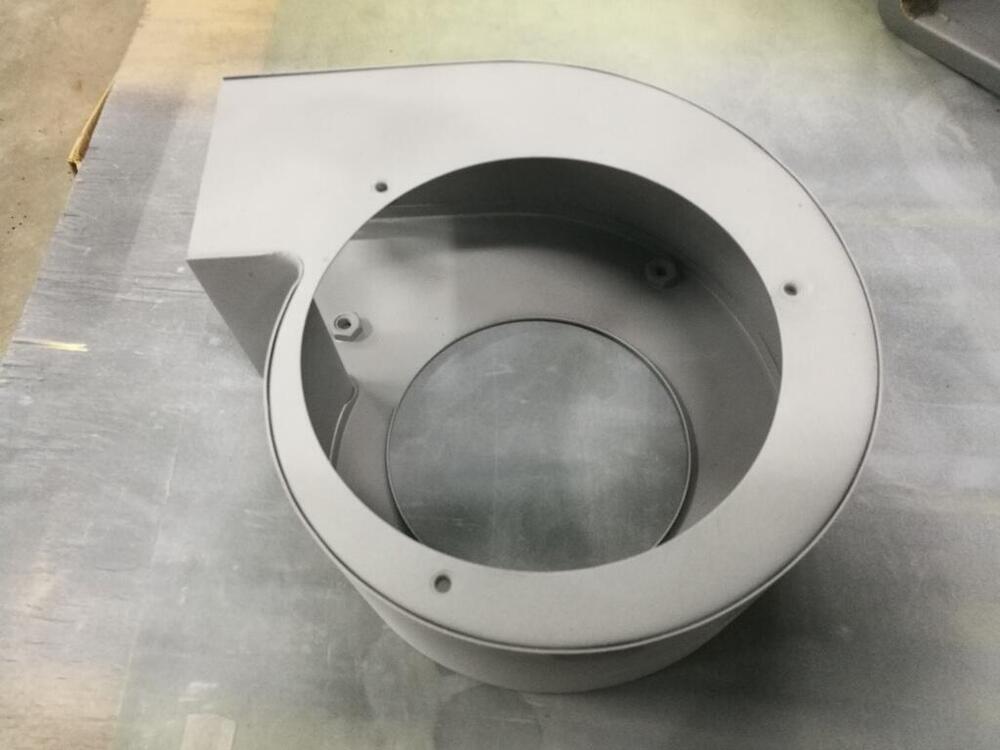

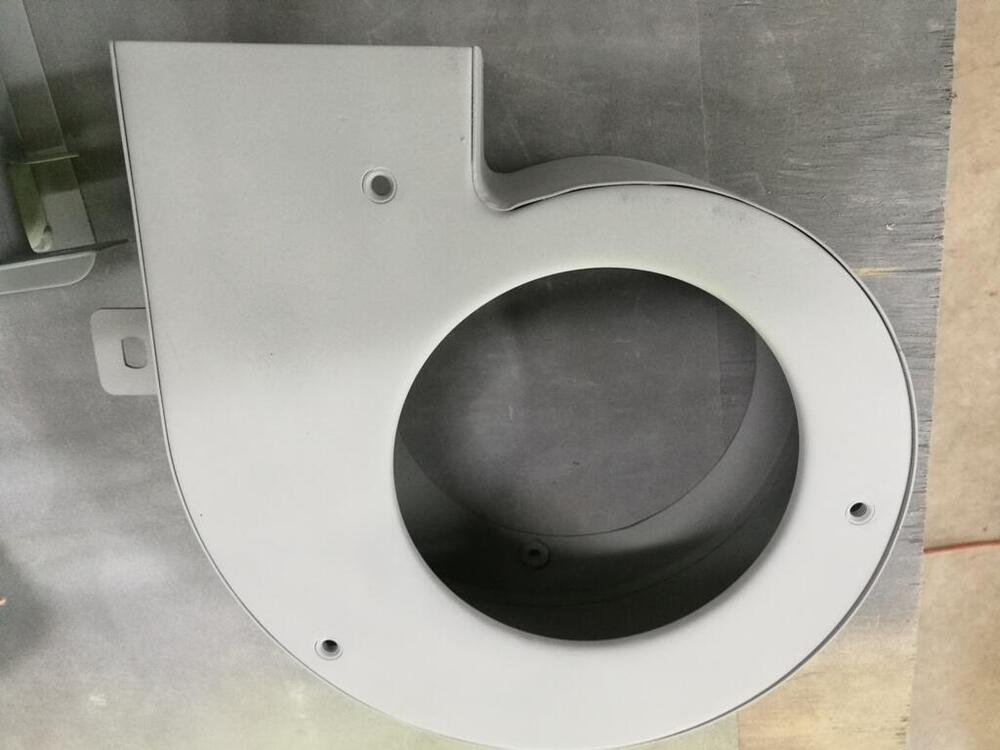

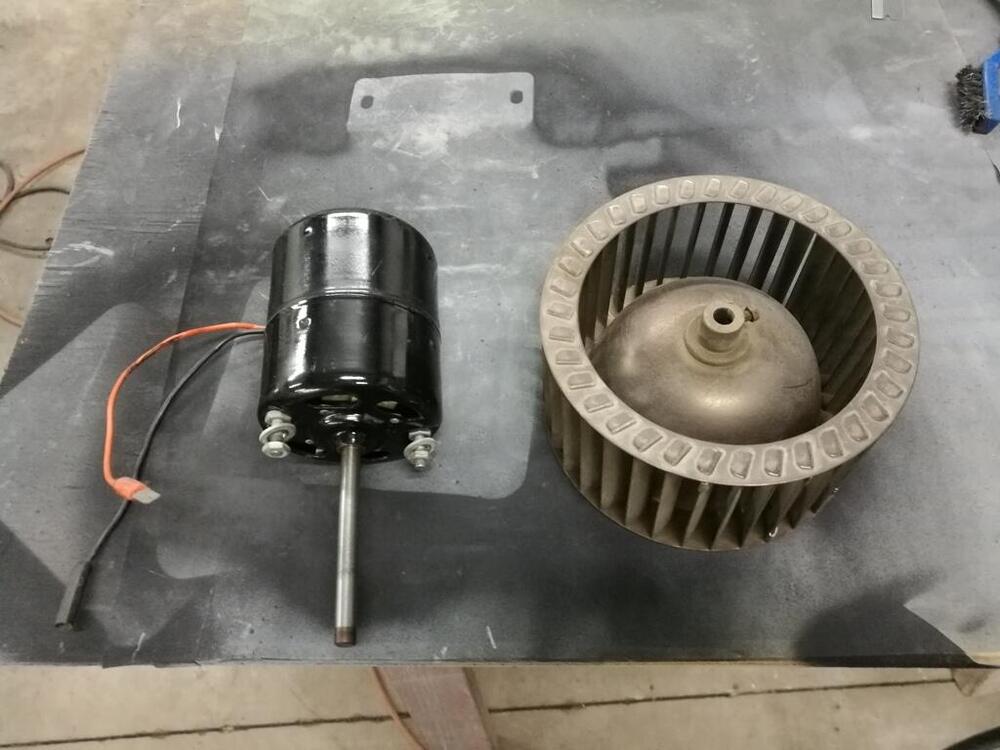

For most of the day, I battled with the bumper and the bumper brackets. I had already put many hours into the front bumper because it had some damage. Here is one of the pictures from when it was on auction at Bring-a-Trailer:

And here is one I found from the disassembly stage:

The impact to the bar looks superficial at first glance, but in addition to the dent, the bar was pushed in a bit for a considerable portion on either side of the dent as well. So, in addition to straightening the dent, I had to pull the bar back forward. And some heat shrinking was necessary as well. Anyway, where I picked up today, the bumper was fitting snug on the right side of the car and too far out on the left side.

Every time I bolted the bumper to the brackets on the car, the bumper was slightly offset to the left side of the car. I determine the cause to be that the slots in the front of the bumper brackets were limiting the side to side movement of the bumper. The bumper studs were ramming up against the sides of the slots. To correct, I had to remove the bumper brackets from the car and tweak them in my vice so that the slots "moved" toward the right side of the car. Shifting the slots to the right side allowed the bumper to shift to the right as well. I also used a hand held belt sander to improve the fit of the bumper uprights to the main bar. After several hours examining, bending, straightening, grinding, a little more hammer and dolly work on the bumper, etc. I got it to this point:

Finally, the bumper is centered and I don't have to apply excessive pressure on the left side of the bumper to bring it to its proper mounting location. I have a bit more work to do on the rear bumper, and then I can package all of the bumper pieces up and send them off for re-chroming.

Subscriber

Subscriber 7Points1,282Posts

7Points1,282Posts