With the windshield in, a significant barrier to installing the dashboard had been passed. However, there are still a few things that need to be done before it can go in the car. One of them is installation of the tunnel jute and trim. And that will need to be followed by installation of the heater core and housing and the fan its housing.

I started on the tunnel jute today. As I mentioned before, I bought a roll of jute from England that looks similar to the original. It is dark brown on one side and tan on the other. I placed an old piece of jute on top of the new, and used black spray paint to mark where I needed to cut. I got mixed up for a minute on which side needed to face up, and marked the wrong side for the handbrake cutout at first. But, I realized what I had done before I began cutting and flipped the old piece over. After marking the correct side for that, I used my upholster shears to cut the jute. I nice pair of upholstery shears is a necessity for cutting this - they cut through without difficulty. So, I got the rear one made today, and just set it in the car for this one pic (third pic here).

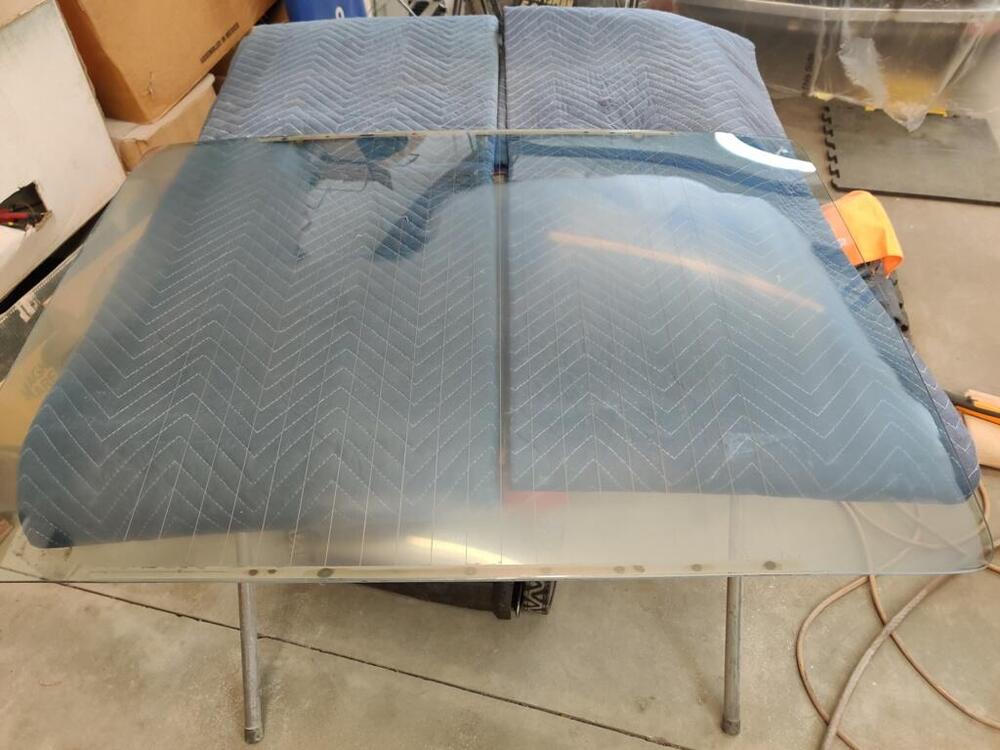

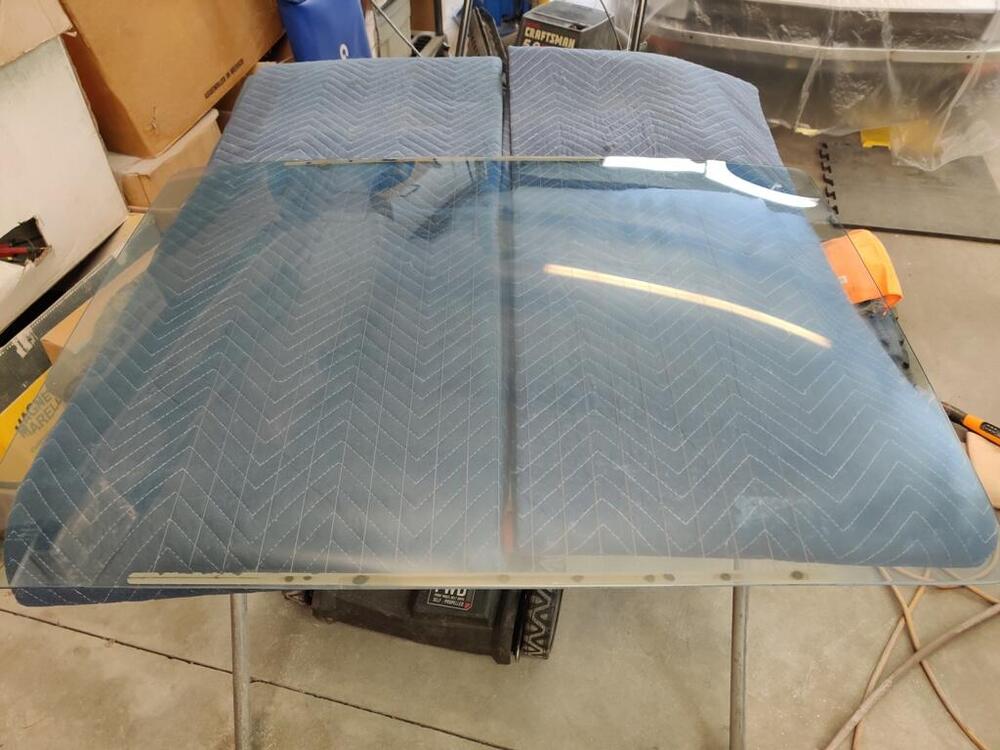

After that, I decided to tackle the job of removing the scratches from my rear hatch glass. As you can see, there are a few - the white beam is the reflection of a florescent light in the shop.

I opened up the kit I received recently, and put the attachment on my rotary buffer. The kit I bought has three different sanding grades and a liquid polish solution. I started with the heaviest grit, putting it on the backing pad. Kind of scary to use this grit as it is super aggressive. One thing to note, I think that out of the box, the heaviest grit "pads" had some oversized grains on it. During the first 20-30 seconds of use, it put some swirl scratches in the glass that took a bit of work (with the same grit) to get out. The kit came with two of the heaviest grit pads. I think it would be wise to run fresh ones very lightly at first to knock any unusual bits in the surface of the pad down a bit before you go to town with it. That, or run it on a piece of glass that doesn't matter to you first.

Anyway, with the first grit, glass removal is relatively quick. I could catch my finger nails on some of my scratches, however, there was not much time investment in cutting the surface of the glass down to past the scratch depth with this grit. When I was done with the first grit, I took a picture. As you can see, a portion of the glass towards the top, center and right side, did not need heavy scratch removal, so I left that area alone:

Next was grit number two. I went over the entire area that I had hit with grit one. It was easy to see the difference in surface finish of grit two compared to grit one. Like the first grit, the second grit cut pretty quickly, but more time was involved in getting all of the areas I had worked with grit one to "grit two" level. When done with grit two, I took another picture:

I repeated the procedure with grit three. I want to say that I getting the surface of the ground area to "grit three" level took a quite a bit longer. Again, I could see the difference pretty well. So, I kept at it until everywhere that had been ground looked uniform, and I couldn't see any heavier scratches from the prior grit. I took another picture:

At this point, I had about 2-3 hours invested. And I switched over to the liquid polish stage. This stage did not go great. Based on my efforts today, getting rid of "grit three" hazing is going to take a very large time investment. I think there are a couple of areas where I did not sufficiently remove grit two, mainly on the right edge in the pics above. So, I may have to hop back to grit three for that area. However, I am confident that for most of the area I have worked, I did a good job of using each grit to remove the prior grit's marks. And unfortunately, this last stage of polishing is going to be a bitch - like maybe 4 or more hours of intensive polishing. I wish there was another grit between grit three and polish.

Of course, I could be doing something incorrectly also. So, I will look at the company's website for some tips and watch some of their Youtube videos to see what I can find out.

Latest pics - second one is that right edge ( I took the picture from the opposite side of the glass) where I think I will need to rework with grit three.

Subscriber

Subscriber 5Points11,142Posts

5Points11,142Posts