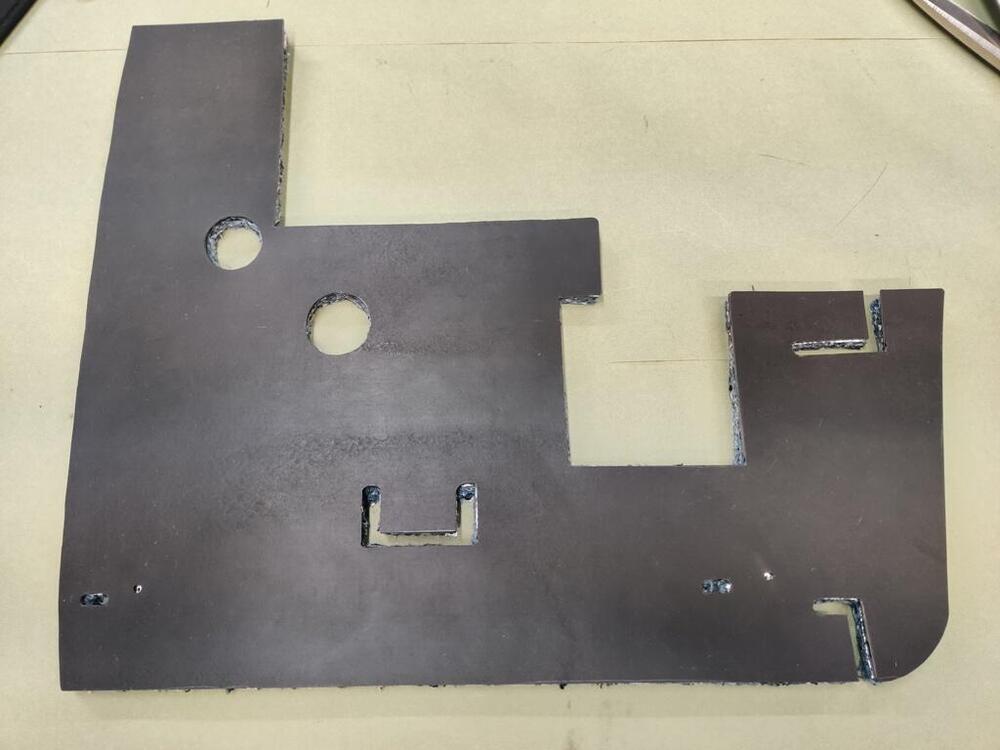

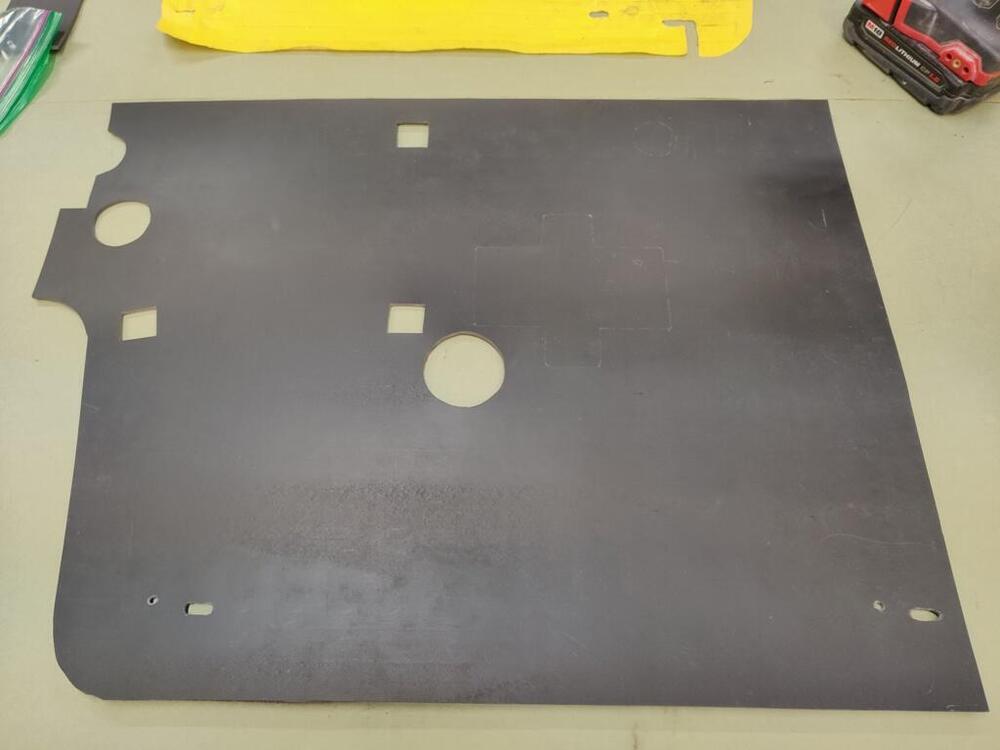

Today, I was able to finish cutting the materials for the left firewall pad, and complete fabrication of the parts to the right firewall pad as well.

For the right pad, I started by heating it up with a heat gun to assist with flattening the bitumen - it had several wrinkles. I used my hydraulic press plates to flatten and cool the bitumen. They are heavy and also helped to cool the bitumen while holding it flat.

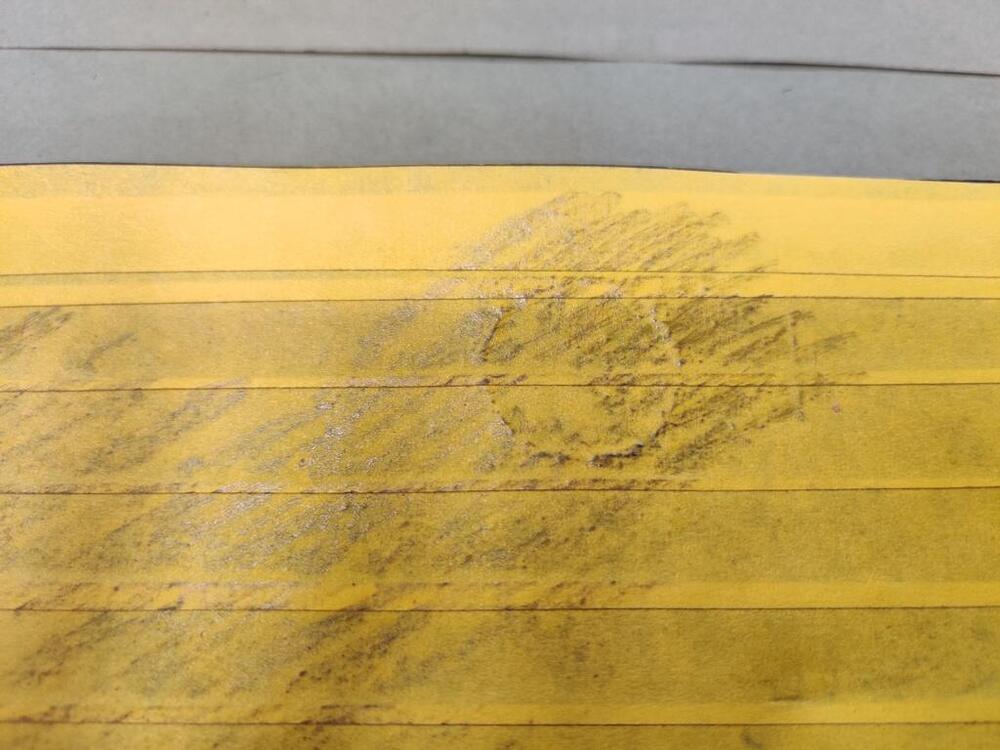

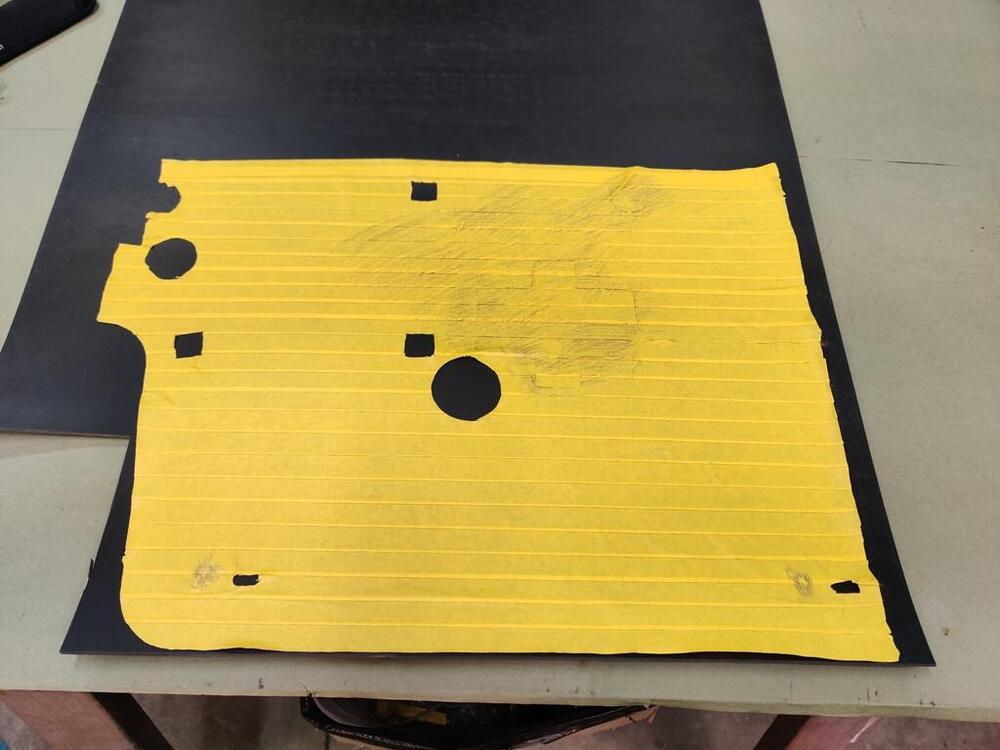

After getting it reasonably flat, I applied tape and trimmed it so it could be used as a template.

As before, I peeled it off of the old and stuck it to the new material. Then, I trimmed the new material to match the tape template.

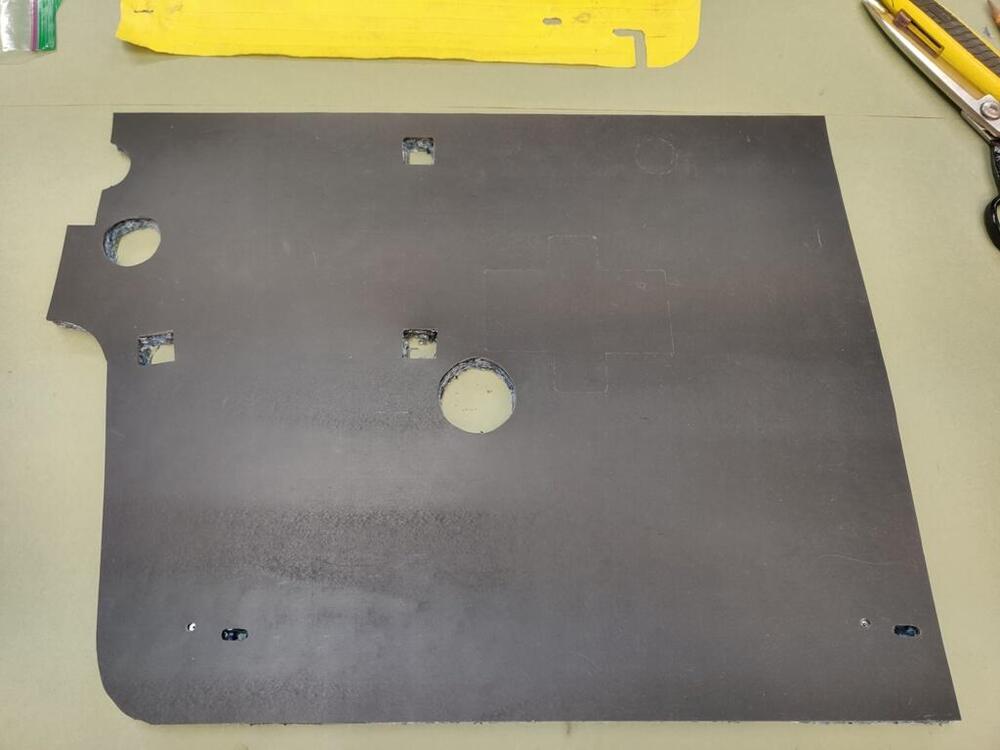

When the new pad was made out of butyl rubber, I laid it on top of the new insulation and marked the cutouts.

I used a black Sharpie to mark the foil. I think it took about 3 and half hours to make this part.

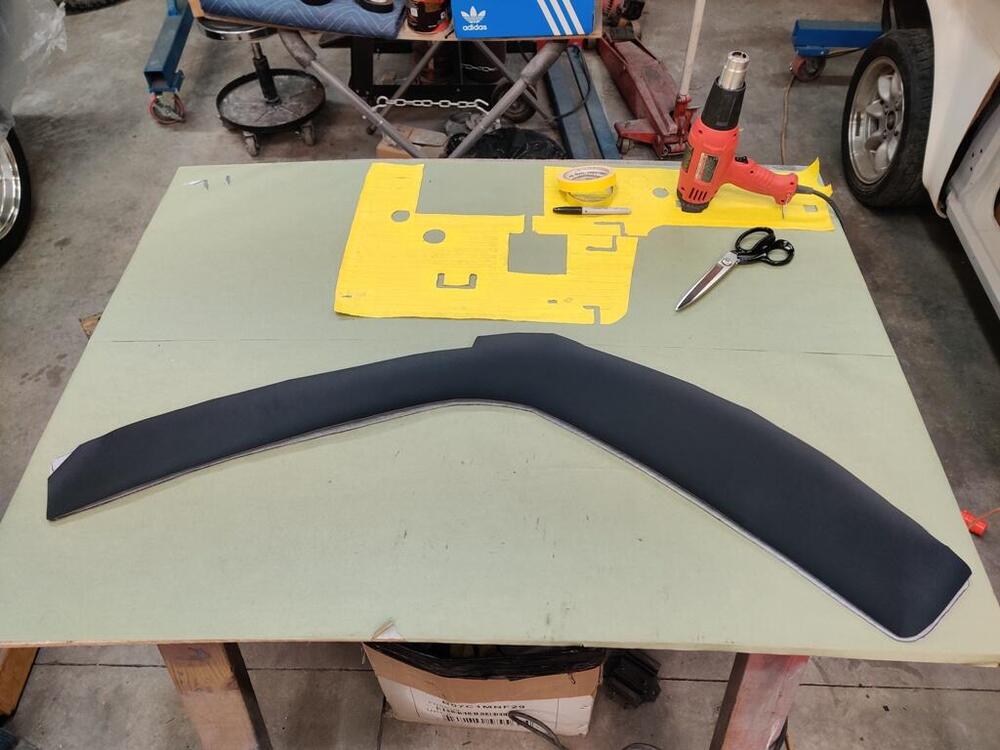

Then, I grabbed the old header and A-pillar vinyl. Unfortunately, it would be too difficult to reuse because of all the glue on it, and some tears on the left piece. I found some vinyl online that looks kind of similar. Before cutting the new piece, I used the heat gun again to get the old pieces as straight as reasonably possible.

Then, I drew on the backside of the vinyl, providing a generous amount of extra on all sides. I cut the piece for the header out first, then one of the A-pillar pieces. Then I flipped over the new A-pillar piece and used it as a template for the other A-pillar piece.

Lastly, I retrieved the old headliner vinyl (with foam stripped off of it) and the new foam piece I bought. I am going to attempt to glue the original headliner vinyl to a new piece of foam. I don't have high hopes that it will work well, but I will give it a try. I bought enough of the foam to make a second headliner. If I have to, I will attempt to find a new piece of vinyl that will be suitable for a headliner, and glue it to this foam.

Subscriber

Subscriber 4Points1,282Posts

4Points1,282Posts