Thanks for the comments everyone. I have decided to use the new ones. I will think about how to check driveshaft alignment, and maybe I can report back what I find when I get to that part of assembly.

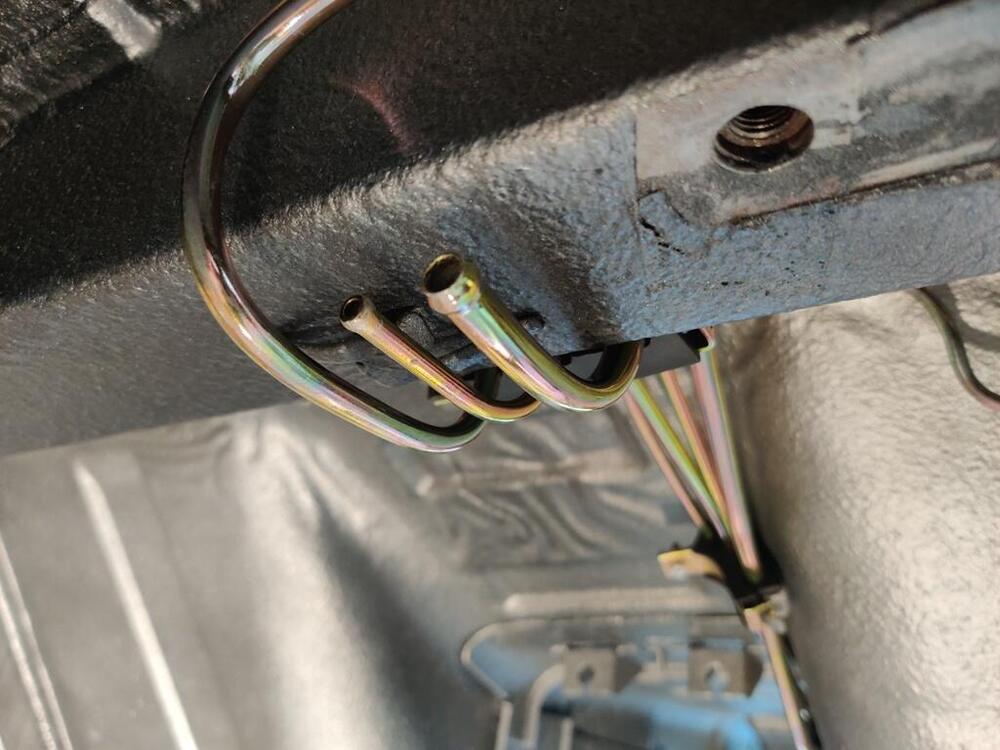

Over the past two weekends, and for a few hours during the last week, I put my attention to the hard lines. I think it was @motorman7 that I got the tip from for bending the lines for shipping and plating. I used a welding gas cylinder as a "form" and bent the longest lines around it. The 180 degree (or so) bends in these are the result. Unfortunately, either during shipping back to me, or during the plating process, several of the lines got rather "jacked". The vapor tank vent line was especially messed up.

I think I have about 10 hours in just straightening and getting the lines refitted, assembly of the brake proportioning valve, etc. I sourced all new rubber insulators for the hard lines from www.240zrubberparts.com.

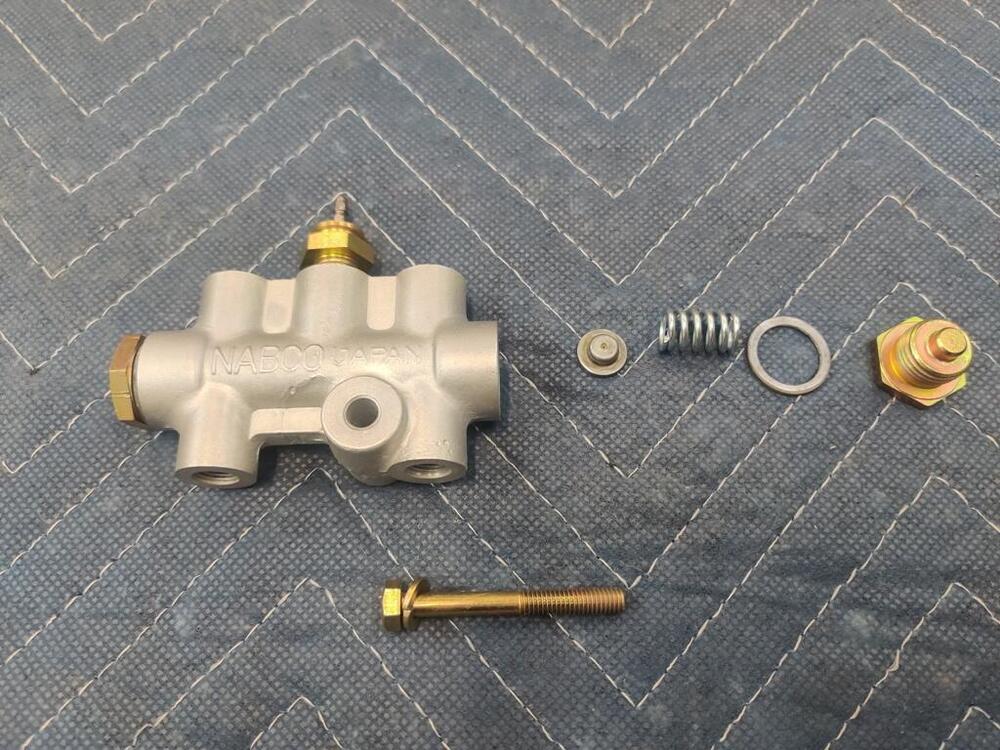

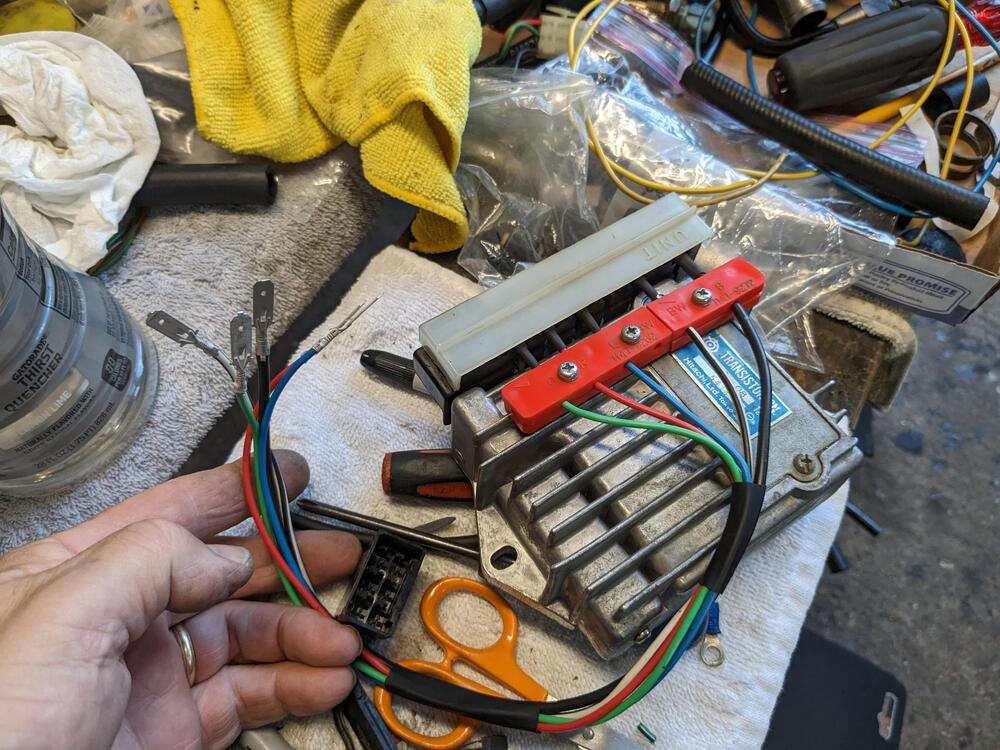

proportioning valve was disassembled, glass bead blasted, internal and external parts plated, etc.

I am unsure if there is supposed to be a crush washer under the fitting with the electrical post. There is a rubber o-ring on the shaft of the plastic around the post, so I think that is the only thing that seals this "port". Crush washers are used with the front and rear yellow chromated fittings.

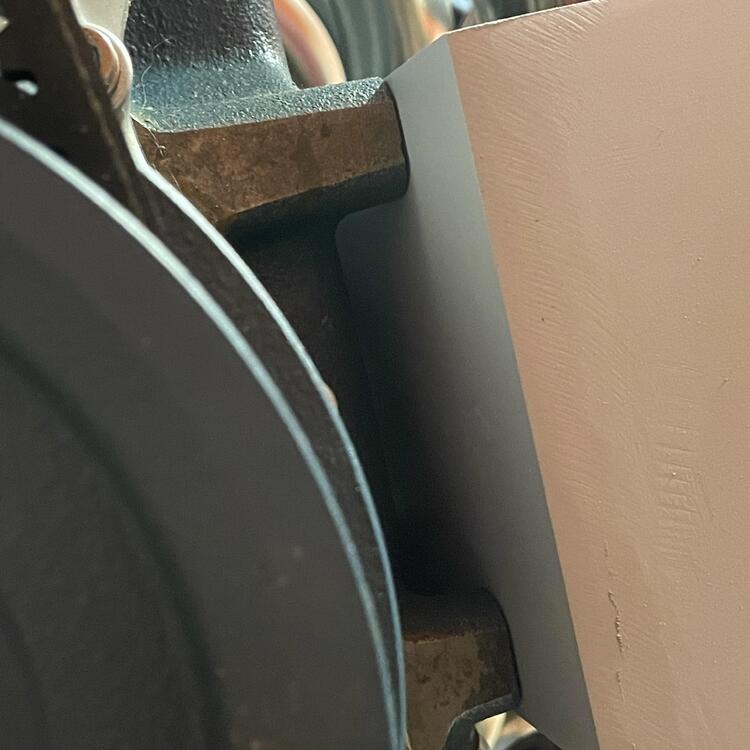

As you can see, the vapor line is reaching for the sky at this point (above right).

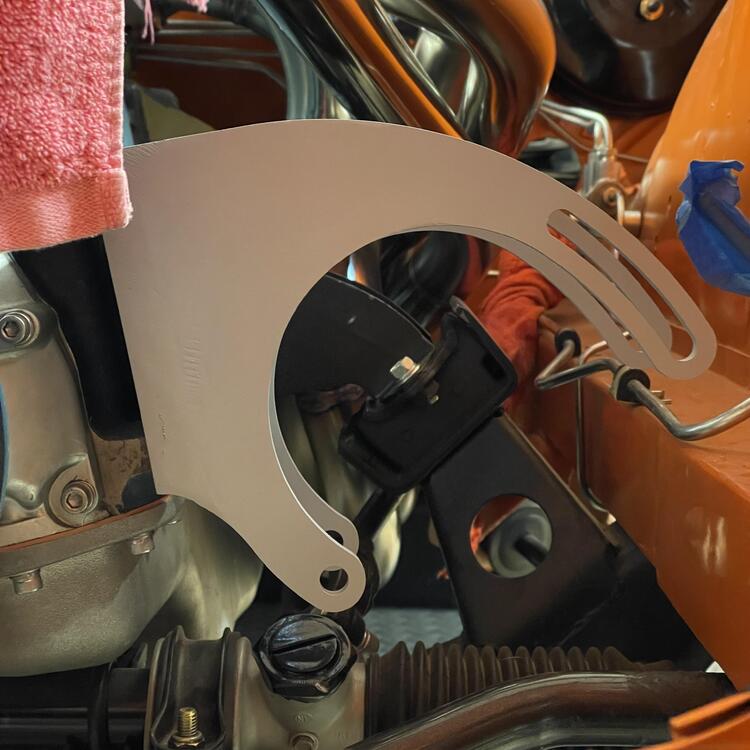

Left front brake line (first two pics) and right front brake line (third pic):

Right front brake line from another angle, vapor line orientation corrected, and rear inlets of fuel lines (third pic):

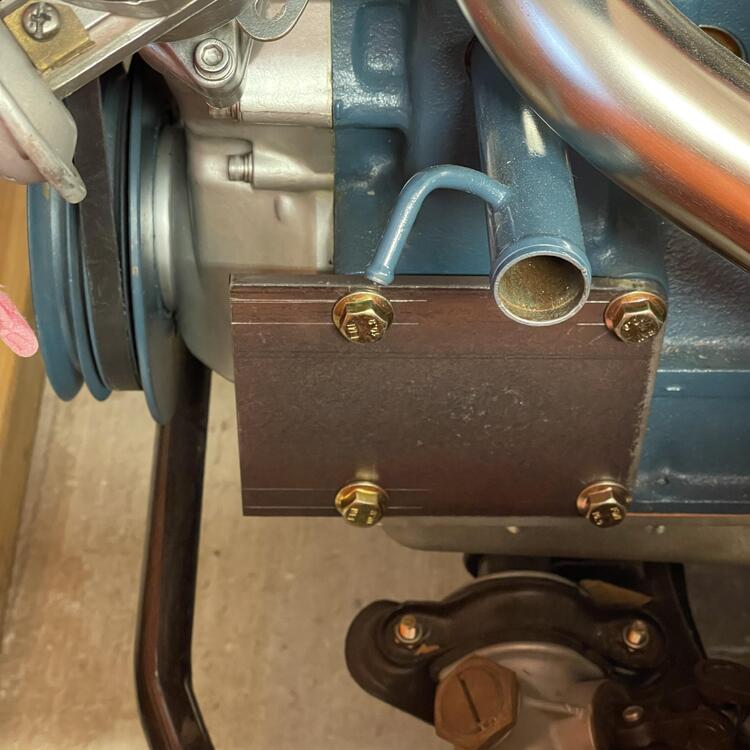

Beginning of vapor vent line, rear brake line, and "y block" and rear brake "delay" valve:

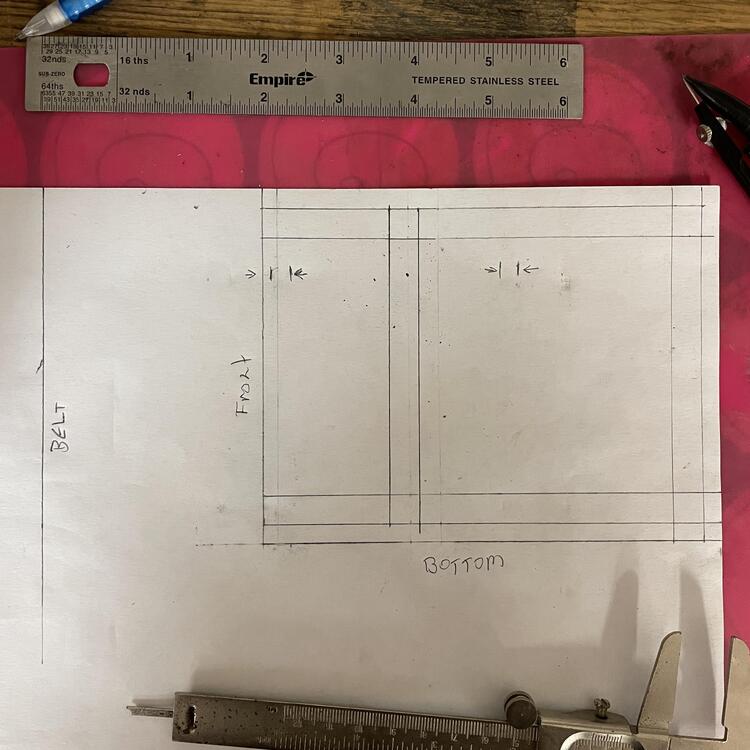

I have several different things holding up parts of the assembly. I still have to resolve the differential carrier backlash issue. The flywheel needs to be resurfaced. I need to paint the steering rack case before I can assemble the steering rack.

I have assembled a long list of reassembly items, specifically in the order I think is best. It is quite long. To share, I will put it into a Google sheet.

Subscriber

Subscriber 6Points1,282Posts

6Points1,282Posts