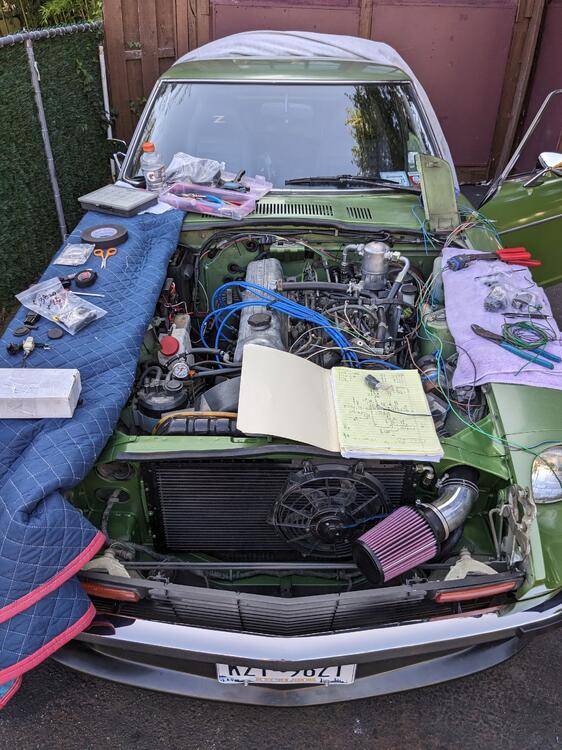

I have been in the process of putting my rear trim back together (from troubleshooting and cleaning out all the fuel vent lines and expansion tank) and I have come to the realization that when you get into the classic car game as a much later owner, you inherit ALL of the previous owners' sins. This is compounded by the fact that I like things to be very organized and just as they should be. I also don't like just doing something partially and calling it good enough - my completed work should be almost to the level of the manufacturer's original intent and quality, which I am sure is probably borderline OCD. I noticed several trim screws missing, found a rodent nest behind the rear light panel trim piece, and this pretty substantial customization of the speaker mount. Anyone know where I can find a replacement? These don't seem like an easy to find replacement part, so it may just be that I have to live with it as-is, as well as the age deteriorating vinyl underside the is separating from the rear carpet and gets worse every time I move it.

I was also able to replace the aged and broken spring on my rear hatch closer. As it turns out, the springs from a standard retractable ball point pen fit or will at least work until I can find the real spring.

We also went to a Cars & Coffee event at our local Detail Garage last Sunday and were again the only Datsun there. A good time but a little hot, luckily, they had flavored ice instead of steaming hot coffee. It's always cool to see what projects people put their heart and soul into, our favorite this time was an old Dodge Challenger set up for the drag strip. My son had a lot of fun trying to figure out where the parachute release was located (turns out it was adjacent to the rearview mirror).

This weekend I think I may start getting a list together of things that I want to remedy over the winter and I am toying with removing the 280Z graphics on the sides - I don't think these were a factory option and they look more custom and vintage 1980's in my opinion. I'm just a little worried that if I do remove them that the paint underneath will be a different shade since it has not been exposed to the sunlight as much as the uncovered paint and the decals have probably been on there a long, long time. I did also notice a disturbing hum when I had the Z in gear and under load (first noticed in 3rd, but then seemed to be present in 2nd and 4th as well). It stops when I go into neutral or depress the clutch pedal. Reading up on here, I am concerned it may be a bearing going bad, so there's more research and diagnosis to come...

Also, if I am going to be doing some significant work over the fall and/or winter months, looks like I am going to have to consider getting a much better jack or possibly a lift for the garage.

Subscriber

Subscriber 8Points11,142Posts

8Points11,142Posts