I decided in the few hours I had to work on the car today, I would make a pipe section for pressing the rear control arm bushings out and remove those.

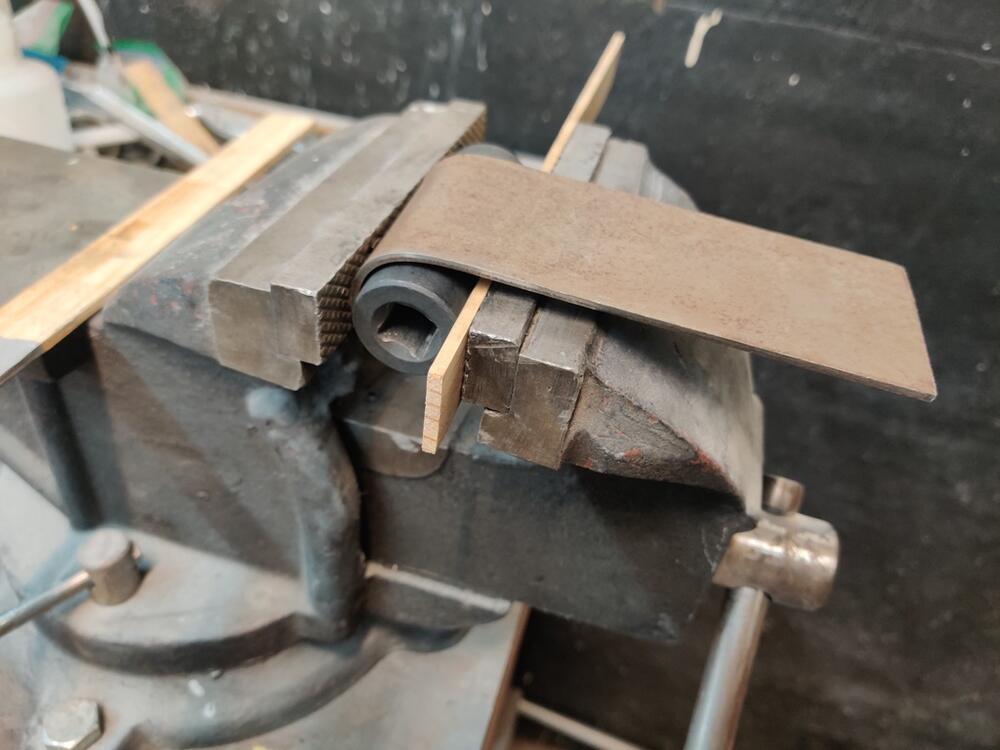

I cut a piece off of my .125 sheet that was suitably wide enough to accommodate the full depth of the bushing when pressed out of the arm, and began bending it.

Using the vise, and an impact socket, I continued bending until it wrapped around the socket. Then I cut it to length and hammer formed it around the socket:

I then welded the seam, dressed the weld with my hand held belt sander, and the ends with my bench grinder. Then, I bead blasted it to make it look nice.

Under an hour and I was at my press with this, the control arms, and various bits to use in pressing the bushings out.

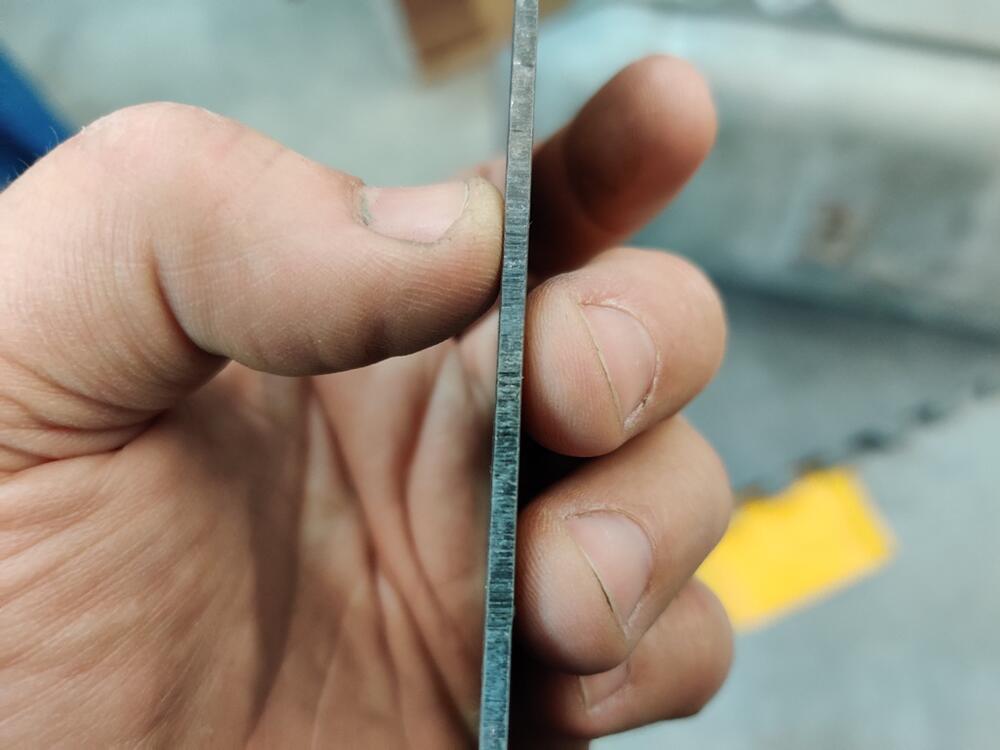

Two hours later, I still hadn't gotten even one bushing to budge a millimeter. OD on a new bushing is about 1.185" if I recall correctly. And the impact socket I was using to press the bushing out is 1.182. It's a bit to big, but I should have been able to get a few thousands of an inch, but I got no movement... at... all! I tried going down in size to the next thing I had, another socket that was 1.165". But it wasn't catching enough of the bushing outer sleeve. These bushings have a very thin outer wall sleeve.

In frustration, I took a hack saw to one of the bushings and cut through the inner sleeve. But, as soon as I got through it, it collapsed a bit and kept the hack saw blade from moving in and out anymore.

What a royal pain in the arse. First time I have been stuck on something in a long time. I am thinking about burning them out. 😠

I will see what others have done first.