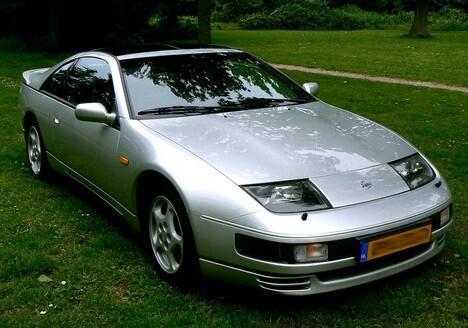

The wiring project is finally coming to a close. I’d argue that this took more work and effort than the engine rebuild and I would definitely rather rebuild an engine than another wiring harness 🙂 I envisioned that when I designed my own wiring harness digitally, it would make the whole process much faster, and in a way it did, but not how I imagined.

What I learned by drawing out my own harness was more informational. I learned how everything worked, I became familiar with the OEM harness in both identification and functionality, and I may have gone a little crazy tracing black and white lines for hours on end. So going into this project I knew what I wanted to remove, what I wanted to replace, and what I wanted to add. I had the new diagram printed out in a 2x4ft poster for the garage and was ready to use this as my guide, but in all honesty, I probably looked at that poster 5 times in total.

Once I started the actual wiring, it was far easier to do a combination of tracing OEM wires and using the OEM diagram. I still needed to find the correct length of each wire, so I needed the OEM harness with me anyways. This was also my first electrical dive into the car world, so I wanted to use the OEM diagram to ensure all circuits were correctly terminated. I think someone who is more confident in their wiring capabilities, and knows all lengths of wire (at least the minimum length needed) could use a self drafted diagram only. It just didn’t work for me.

Now, enough boring talk, let's dive into what I used, how I used it, and what's next!

Parts used:

It was a bit of a pain sourcing electrical items with the current COVID supply chain issues. I knew I wanted to use 280 series fuse and relays for everything. I can't stand the look of regular sized relays, let alone 6 of them side-by-side. I also knew that I wanted to update all original relays and connectors to modern technology.

Originally, I wanted to use a Bussman Distribution Block:

This was my first choice since you can neatly organize your relays on the left, fuses on the right, and choose if you want busbars integrated or not. Unfortunately it was tough to find what I wanted in stock and I knew I would need a minimum of two to fit the amount of relays and power sources I needed. So I ended up using a GEP Distribution Block:

The GEP block is similar in that it allows for 280 series terminals but allows for more flexibility in placement. The downside is there are no busbars so you will need external setups for your power in and ground.But it was available, so I can't complain! I picked up two generic busbars that had covers to hide most of the mess. It would have been so nice to just run one power wire though, via the Busmann Box.

I paired this with 280 series relays, the simple 4 pin relay we all know, just smaller form factor. Do note, that while this is a 4 pin relay, it occupies a 2x3 portion of the distribution block. Still, I was able to fit all relays and all circuits in this 96 pin block with room to spare. Make sure the relays you order are for 12V and not 24V and rated for the amperage you need…I may have ordered up the wrong set initially.

Next was my relay for the main power. I used an 85 amp weatherproof solenoid. Same function as the smaller ones above, just heavy duty as this is is handling all power to the car (minus the start motor):

The circuit breaker I chose is okay. It feels cheap but is rated at 120 amps and is “waterproof”. We’ll see how long this lasts but I don't mind changing this out in the near future for something closer to the 85 amps of the solenoid. For now, it works and is a nice extra layer of safety:

I was going back and forth on connectors for a while. Deutsch style, AMP style, Weatherpack style, there were so many choices and everyone has an opinion on this. Pick what you like, anything is better than 45 year old plastic at this point. I chose weatherpack because it was easy to source and the crimping tools did not cost me hundreds of dollars (I'm looking at you Deutsch….).

Funny enough, I don’t think I would recommend weatherpack if you’re doing a full harness. Or at least not only weatherpack. I used the Metri-Pack (APTIV) 280 series. And while yes it worked just fine, I didn’t like how limiting this series was. With a 6 pin connector max that was a 1x6 setup, I constantly found myself wanting 8,10,12, even 14 pin connectors to clean up the look. Luckily they do have a Metri-Pack GT 280 series that is a much more modern design with connectors up to 16 pins. There are some amazing bulkhead connectors out there as well, but it wasn’t in the budget at the time. Don’t cheap out on the terminals and seals. I bought a pack off Amazon as I was short a few, but the metal is so much worse. The knock off connectors I found to be a decent copy but with slightly worse tolerances. I used these as a last resort.

Lastly, the wires I used were a GXL rated wire. I picked up a pack of 18 gauge, 12 gauge, and 4 gauge for my battery leads. I would probably swap the 12 gauge for 14 gauge next time.

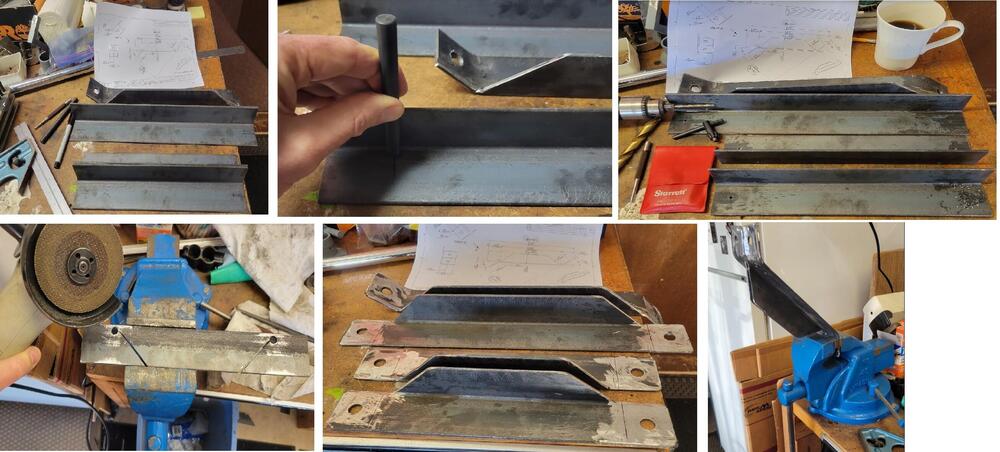

So, we have all of the supplies, a plan, and LOTS of time to work…let's get started. I started by bringing the OEM harness to my “workshop”, aka my kitchen, and taped off connectors I knew I didn't need. Things like Air Condition, excess relays, emissions, interlock, etc. I then started with the longest wires and traced them with my new GXL wire for length. I labeled each wire to keep things documented. I only used 11 different colors and rarely had issues with micing up cables. I tried to logically use them so no two same colored wires went to a similar spot or into one connector. Once a connection was complete, I would tape the old connector as well to let me know I finished.

Doing the tracing took me a full evening for the engine side. I then tackled the dash and body. My connectors here on the OEM harness weren't bad so I decided to keep the original setup and splice my two setups together. Looking back, this worked just fine for the body harness but I wasn't a fan of doing this for the dash. The dash wiring gave me more headaches than the engine bay and body harness combined. Anyways, once my harness was laid out, I wanted to toss it in the car to see if my lengths were accurate and to give me a visual aid if I missed any wires:

Everything fit perfectly and erred on the long side which I was happy with. So I could start the terminating process! Does that make me The Terminator?!

This took the most time and definitely was the most tedious. Each wire needs a weather seal and pin lined up in the crimper. It was also overwhelming on where to start. I have this huge mess of wires and was lost on “Do I start with the power side, or the accessory side?” I wanted to follow the flow of the current so I ended up with the power side. I mapped out my distribution block and just started one by one. It was easy to get lost in the wires but just do one circuit at a time. Each lead off the distribution block had about 10-12” of wire which would then terminate to a weatherpack connector. I would then match this with a connector at the start of my harness and connect the two once complete. I did not terminate the accessory side of the harness yet so I could trim the wire to the length needed once in the engine bay.

About 15 connectors later I am ready to start testing this spaghetti, mama mia! I immediately ran into a couple issues that I would highly recommend people do differently! First, as soon as I layed the harness in the car, I saw my absolute abundance of connectors under the dash. Was it functional, absolutely. But it was just a disaster there and I bet driving down the road would sound like a toy bin with all the connectors bouncing into each other. So I ended up ordering a pack of 12 pin connectors that would consolidate my setup. I used a 12 pin for the distribution block to the engine bay, and another from the distribution block to the dash. I do have a few weatherpacks thrown in for the body harness for my 12 gauge wires.

The other issue I had was with my distribution block location. I knew I wanted to use the original fuse box spot, but when I did my wiring, I didn’t have exact lengths for everything (Block to busbars, block to harness, etc). I would suggest people tackling this to make their mounting plate first, then start your terminating. I had to shorten everything after I made my plate, oops!

Once we settled that, I could start running my main power. I ran 4 gauge wire from my battery to a 125 amp breaker. From there, we travel to the 85 amp solenoid. This is triggered by a master kill switch on my switch panel that always sees 12V (through a fuse). This will finally feed power to my distribution block.

I didn’t want to hack up the original mounting plates so I used existing holes and I am satisfied with how it came out. I would prefer the breaker to be hidden but I can always move it in the future.

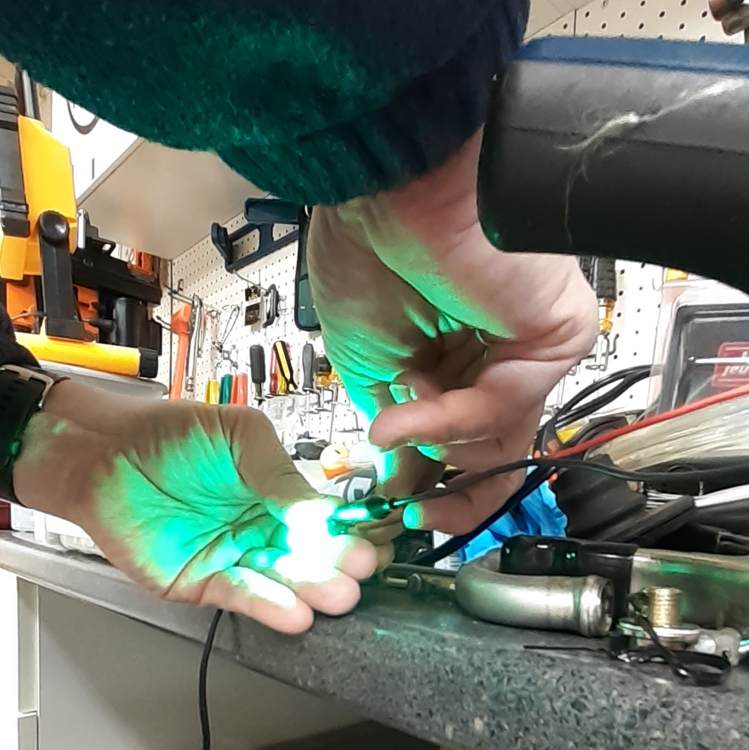

So I have power now and the testing can begin. I started with simple circuits like my fan relay, starter relay, etc. I created a spreadsheet that lists all circuits and if they were functional yet. In my previous posts, you will see that I ran into a couple hiccups along the way but nothing major. I can't tell you how many times I wasted 20 minutes or so diagnosing a circuit when either the main harness wasn't even connected or my power switch was off! Too many things going on in my head and I lost track of what was done. I mean c'mon, this looks organized right?

…right?!

What a mess!! It looks worse now than when we started. But I promise it works! And I promise not to shove it up under the dash as is 😄 There are a few items left to still test, but I cant before the engine is hooked up to the new carburetors. Things like oil pressure, alternator, tachometer, etc. I feel confident enough now to start looming my harness and wow what a difference this makes.

The harness now comes back out again to get a last review to make sure all of my splices are sealed and nothing is mangled up. In my spreadsheet, I updated all of my notes to match what color wire I used, where it is pinned, and when it sees power. This changed a couple times during my testing so I am glad I did this step last.

I used this split loom in various sizes to wrap. It was very nice to use and allowed for T-offs very easily. This was also nice to use since I didn’t need to remove my connectors to wrap.

Each end was also taped up with some fabric tape just to ensure nothing would shift around or unravel. I grabbed a firewall boot to help keep the elements out as well. Here is the final product, a fresh harness! I am so pleased with how this turned out.

I hope this helps you guys with any wiring projects you run into. Feel free to ask questions about specifics like what pins I used, what tools, quantities, prices, etc. But this post is already mega long so I spared you the details 🙂

But now what? The carburetors are getting dismantled for the ultrasonic cleaner, and rebuild kits are ordered up. Once every circuit is finalized I will move my way to the interior, finally!