I did eventually get all this done, I just neglected to update the thread. I've attached a few pictures:

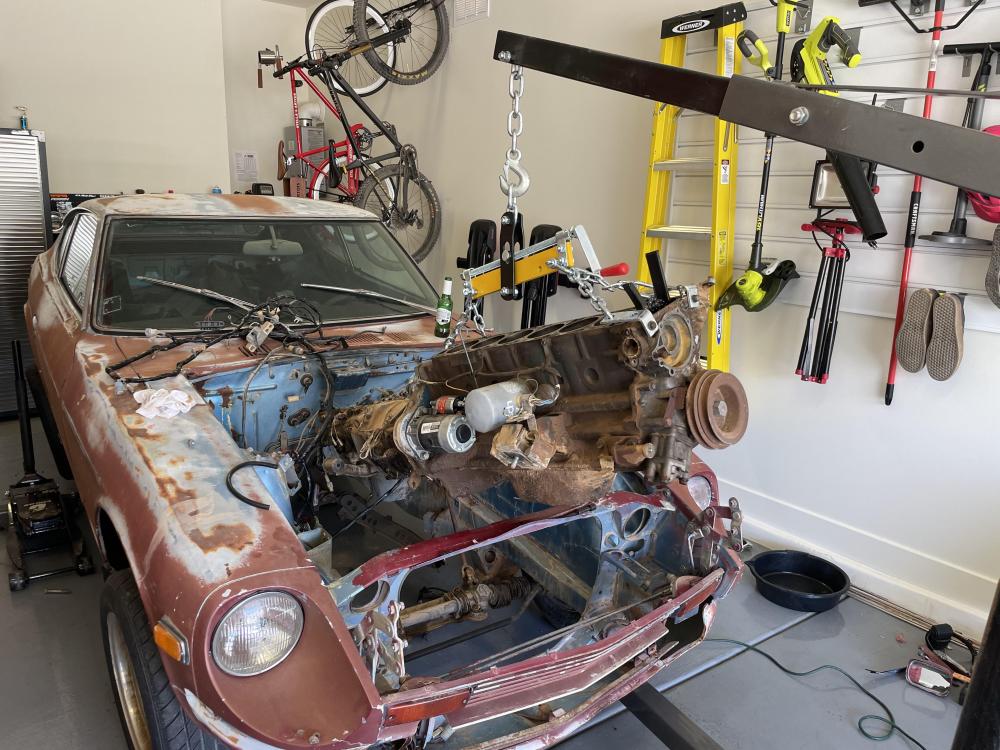

I really only reinstalled the suspension so I could get the car outside to start to clean up of the wheel wells. You can see some signs of initial experimentation that proved it wasn't a good job for the garage. There seems to be a solid, stubborn layer of dirt over undercoating, over paint, over primer. I believe (aside from the dirt), it's original (factory primer and paint, and dealer undercoating). It's going to be quite a job to clean it all up, but there's a real mix of conditions. In some areas, all layers are intact and solid. In others, I can see paint and in a few areas there's rust. The small reinforcement panel above the point where the TC rod connects to the frame has rotted through on both sides (you can just see the left edge of the hole I knocked through it in the first picture). I've hammered away elsewhere and haven't found any other soft spots in the wheel wells, but I think it makes sense to remove everything and re-coat the whole thing. I took the passenger fender off and things aren't too bad there. No paint or undercoat (and not a lot of dirt). There's rust mostly on the horizontal surfaces under the top of the fender. It isn't so bad cleaning these parts up. There's another rotted bit at the lower front of the outer rocker panel where I see the cowl drain conveniently dumps water. I'm not a welder, so I'll have to have these repaired by someone who knows what they're doing.

On the positive side, the car started up instantly after the winter. It's running very rich, but that's for another day. It's fine for moving it in and out of the garage, although the clutch engages very high, so I'll probably have to have a look at that. It seems to disengage at a reasonable point, which seems like a weird combo to me. Like I said at the beginning of this thread, this will likely be a multi-year project!

Subscriber

Subscriber 6Points3,770Posts

6Points3,770Posts