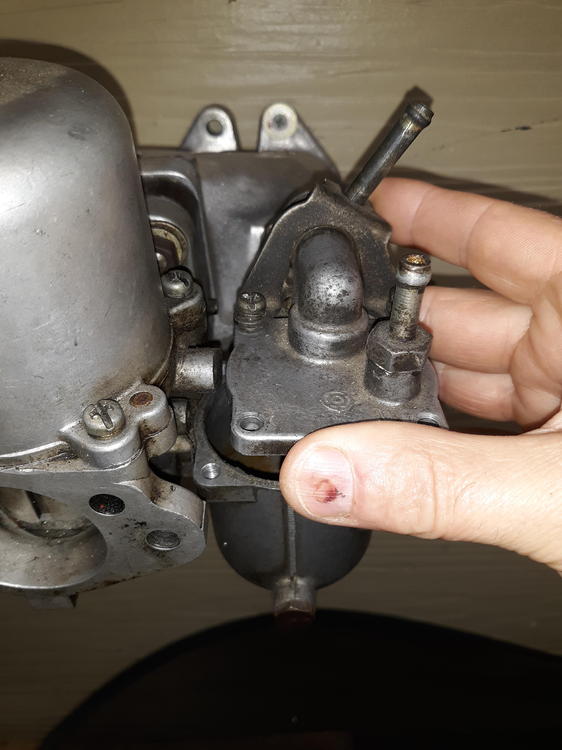

ok that looks like mine, only diff is the extra ground wire from the green wire on the term block that mine has.

A guess here, the AFM is electrically isolated from the chassis due to the use of the rubber gromments used to mount the plate to the chassis (I presume to damp vibrations). So with all that air flowing thru the alum body of the AFM it could build up a static electrical charge with out the ground lead.

So that lead makes since but my grounding of the diff green wire does not. My play is to get one of the HEI modules as ZH has mentioned just as a backup, will wire it up and just control the coil by choosing which module is hooked up. I read some comments by ZH in another thread where he just left the OE stuff in place and would just disconnect the signal at the OE module and then hook this one up under the hood.

All this is really just so I don't get stranded on one of my long road trips, so a tested backup system would be nice to have.

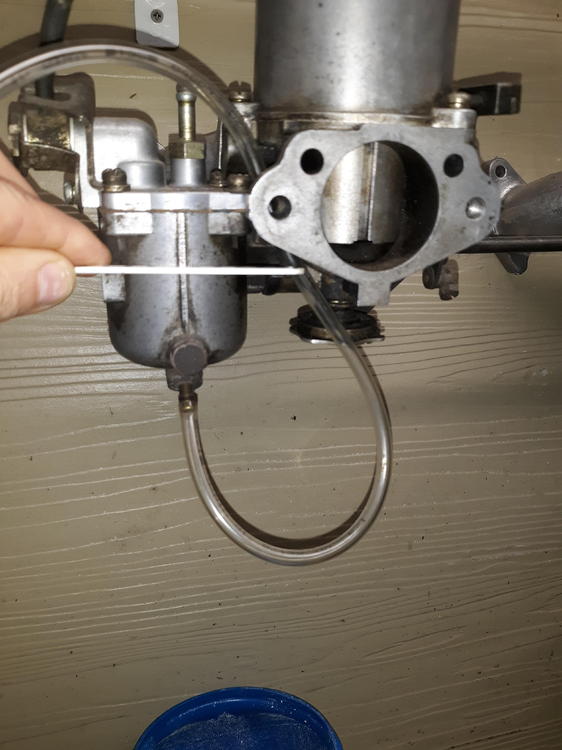

oh btw my test stand engine does NOT have the AFM grounded, something I will take care of since I don't want to smoke an ECU.

Subscriber

Subscriber 2Points3,770Posts

2Points3,770Posts