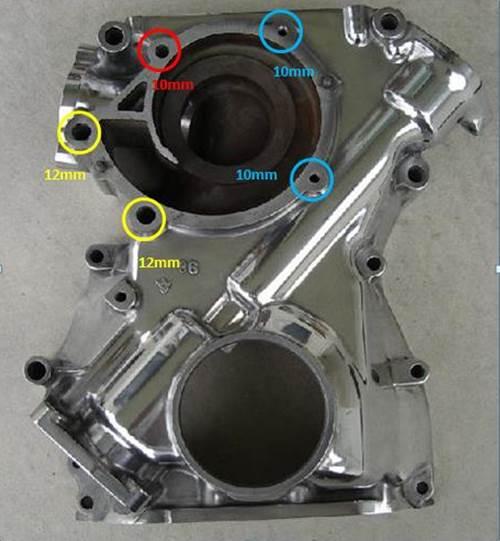

I wonder how many thousands of Z's suffered from this particular affliction. The problem bolt is the 10mm (M6) item located at the 10:30 position...

x

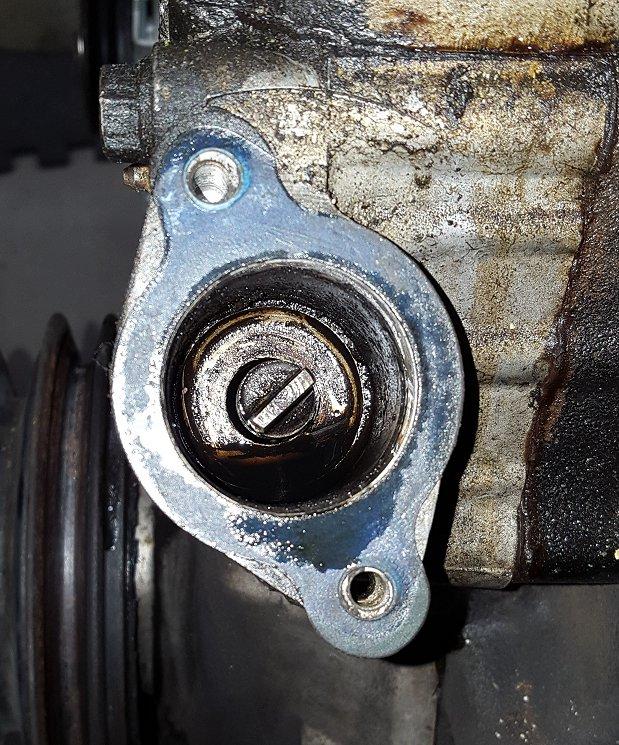

I think that innocent-looking bolt head probably fools a lot of first-timers because it conceals the fact that the hole in the timing cover is just a pass-through, with the bolt actually threading into the front face of the engine block. That means there's an inch or so of freestanding length sitting proud of the block face -- permitting just enough wind-up under wrenching torque to trick you into thinking that the threaded part is starting to move. And then.... 'SNAP'.

Just for fun, I simulated the set-up by locking a 10mm bolt (6mm shank) in my bench vise and then using an old-style torque wrench to see how much torque it would take to snap the bolt. I located the start of the threaded section right at the face of the vise jaws, with the 1-1/2" unthreaded length sitting about the jaws. IIRC, the bolt broke at under 10 lb-ft! . I was just using a hardware store bolt, but I don't expect that the Nissan OE bolt would offer much more than double the strength. So the threshold between, 'I think it's moving' and 'uh-oh' is about 15 to 20 lb-ft. If the bolt was infinitely strong, I'll bet it would take 30 - 40 lb-ft to break the frozen threads free. So it looks like a losing proposition if your only solution consists of leaning on the wrench just a little harder.

Just for comparison's sake, the bolt torque reference chart for ISO fasteners that's included in Wick Humble's 'How to Restore Your Datsun Z-Car' indicates that the recommended tightening torque for a Grade 4 (per the OE Nissan item) M6 bolt is just 2.5 lb-ft! (and only 6 - 8 lb-ft for the heavy-duty, Gr. 9 version). The L-Series FSM is notably silent on recommended tightening torques for these types of secondary fasteners. What a contrast! Install = finger-tight. Remove = beyond snapping point..

The two other 10mm bolts have their own problems. Just like certain other bolts on the L-Series engine, you have a steel bolt threaded into an aluminum casting, so internal corrosion sets up because of the dissimilar metals.

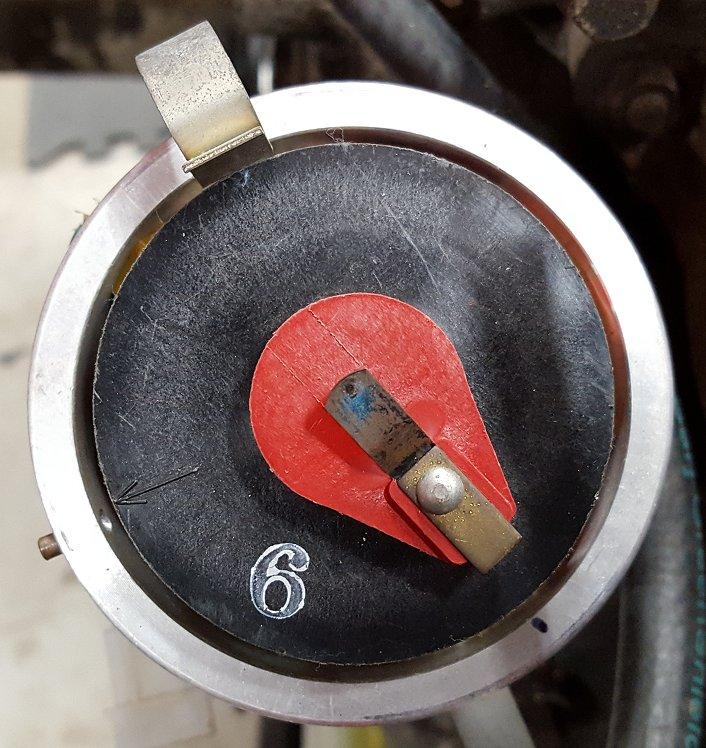

I've had good luck with these timing cover bolts on two different engines by using a small, handheld impact driver and a medium-size mechanic's hammer. Just takes a bit of patience (along with removing the radiator).

Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts