It took a while but I think i've finished my conversion. It looks redneck compared to Captain's beautiful Stainless Steel work. It's more of a bush fix. I’ll try to detail it so the next guy can use it as a starting point to make a better job than me.

So modifying the the airbox door is easy. Used a little piece of steel and some epoxy glue and screws. Must trim the screws flat on the other side.

Trimmed the pipes about ¾’’ and made some sort of a bead using a DIY bead roller made with old vise grips, a washer and a welder. Room for improvement here… but it will do. Also added a piece of foam to the top since it is a bit shorter than the stock one. The foam keeps it nice and snug in place when the airbox door is bolted in place.

I looked for an alternative to drilling the firewall. I realized that 11/16 grommets enter perfectly in the stock hole. I then found these ‘’slip on’’ adapter for plumbing. They are just the perfect size to enter the grommet tightly. A 5/8 coolant hose slides on them nice and tight. You just have to cut the small end.

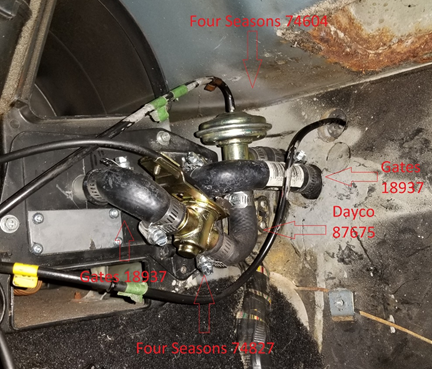

I kept all the valves inside the cabin for now. I used a dayco 87675 hose which I trimmed only the wye part. I went to the auto part store which had a Gates 18937 hose. It has two nice tight 90deg bend in it so by cutting it in half you can finish the rest of the job.

One part that took me a lot of time is adjusting the cable. It needs to be trimmed shorter, and bent correctly but also, the stock valve has a linear front to back movement, the 74827 has an arc to it’s movement. The stock stiff cable did not like that and would bind up. So I made a little adapter using some Delrin. Works like a charm. Take your cable out of the sleeve, polish it a bit with some steel wool and lube it at the same time. There is a good amount to be trimmed off, so trim a little bit at a time until you get the hang of it.

Connected inside the engine bay. If you are quick you don’t need to drop the coolant. Mine was looped , lifted it up above the rad, uncoupled and quickly coupled it again. No major leakage,

Everything looks as tightly packaged as stock, so i'm not too worried about space. I'll confirm once everything is operational.

Subscriber

Subscriber 5Points3,770Posts

5Points3,770Posts