Thanks!

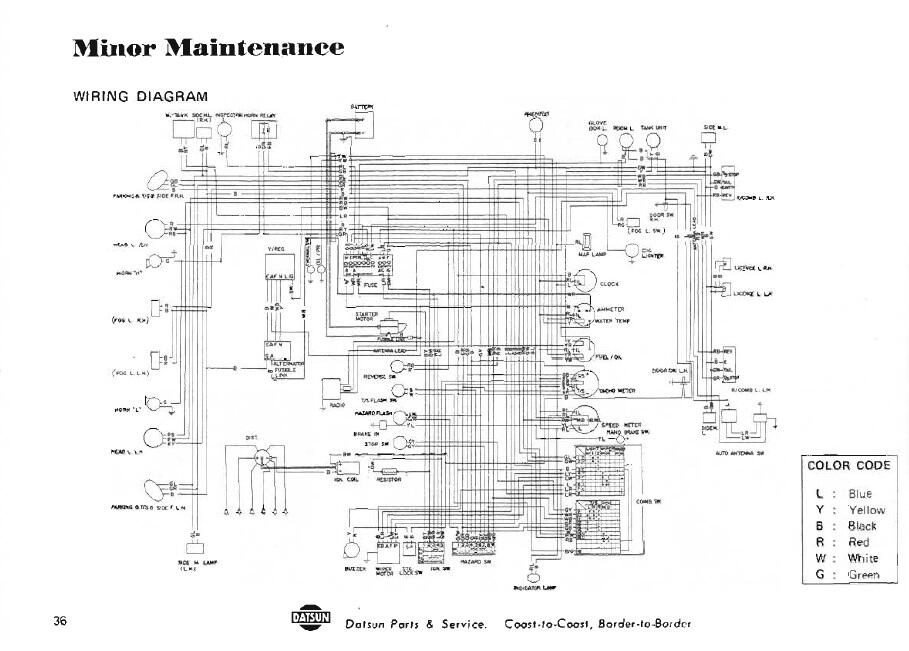

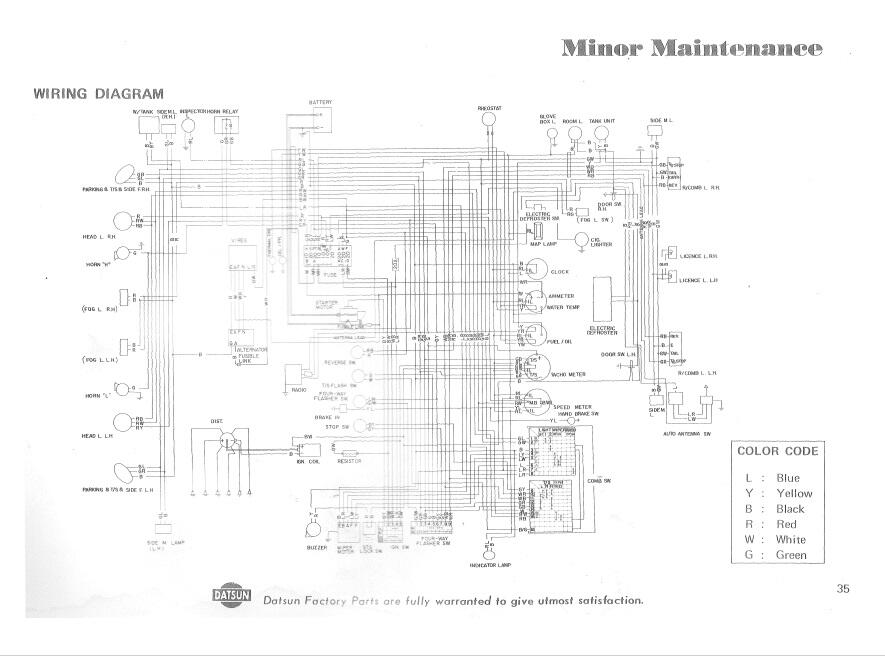

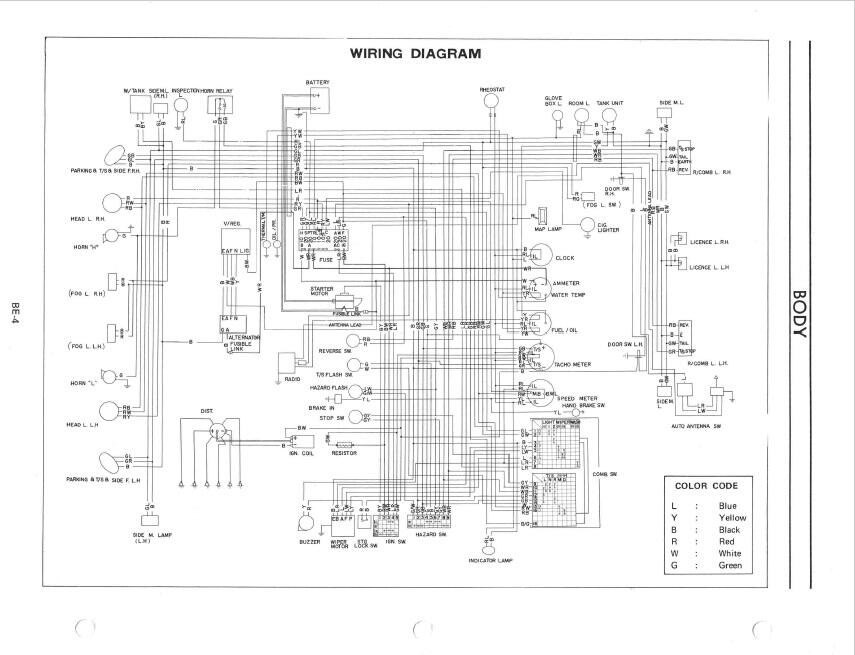

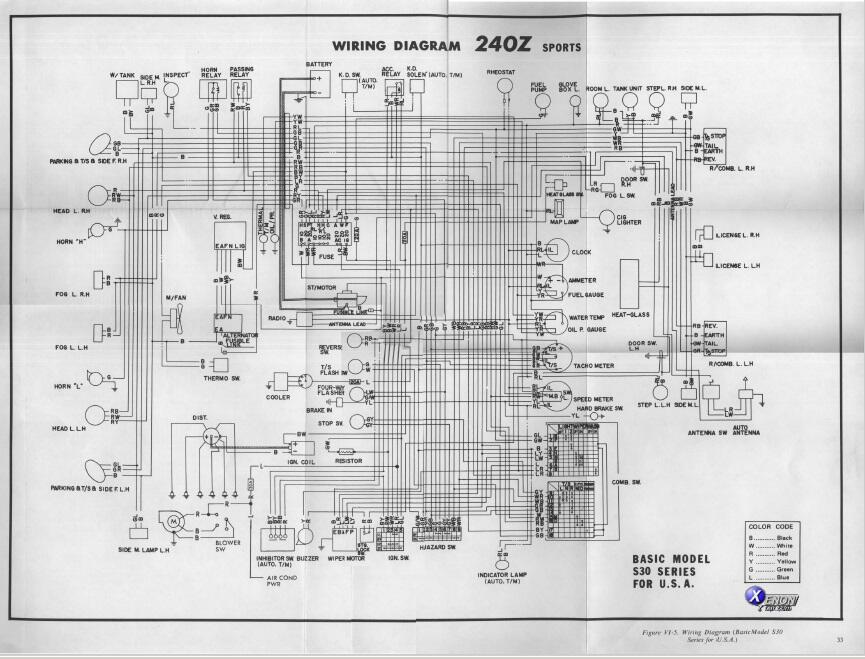

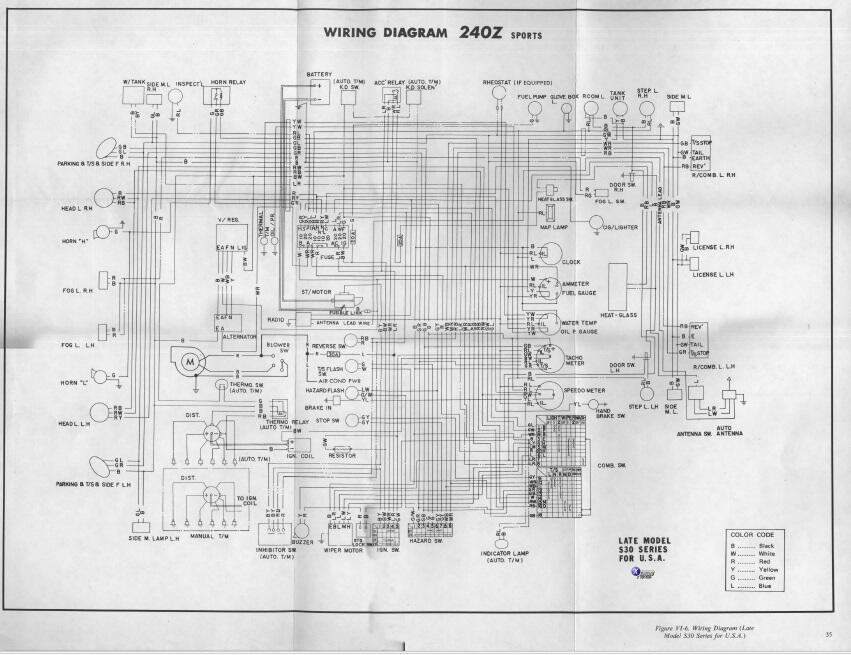

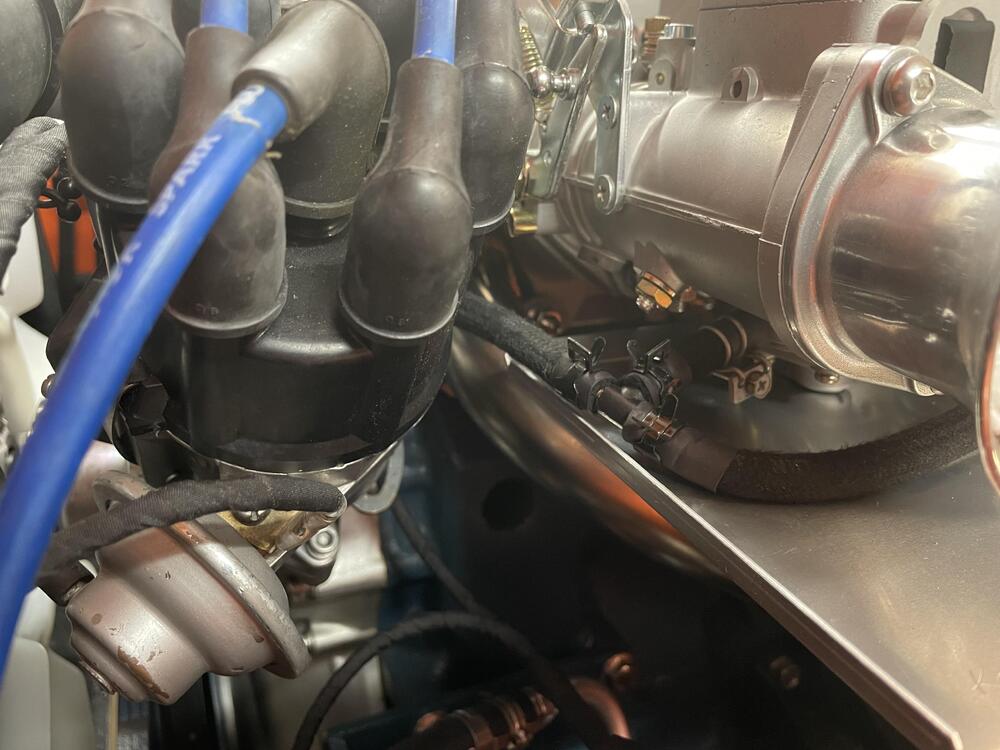

It depends on whether or not I make the dashboard wiring harness a blocker. If I don’t then I only need to jump some wires in the engine harness, make battery cables, fill the radiator, and bypass the heater. I have everything necessary to do those things, so I could theoretically finish all of that in a week.

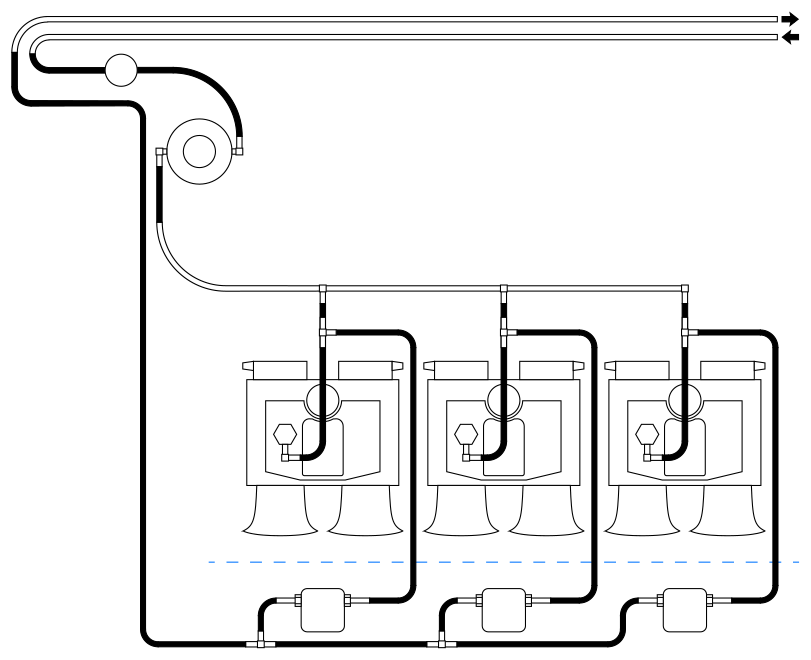

I also need to decide if I am going to fill the gas tank now or have the supply come from an external tank.

Oh, and I need to get the transmission into neutral without having a shift stick, clutch cylinder, or clutch pedal in the car.

Subscriber

Subscriber 2Points428Posts

2Points428Posts Subscriber

Subscriber 2Points11,142Posts

2Points11,142Posts