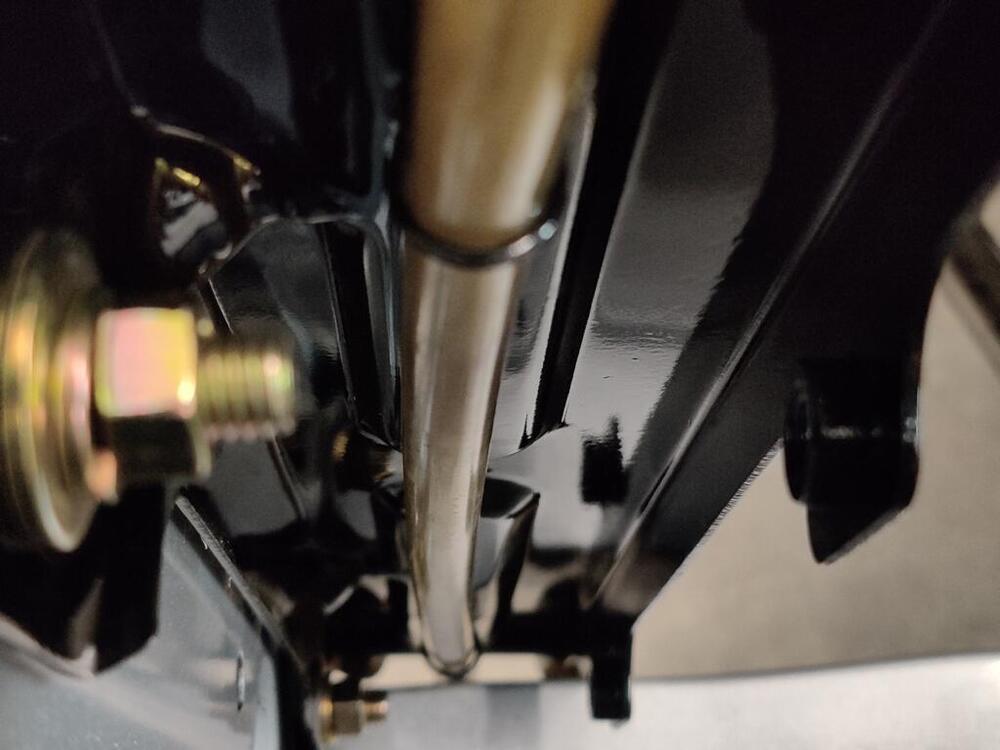

just to clarify the ease part, IIRC after removing all the drive shaft stuff so you can clearly see the tunnel, use a trans jack to support and then remove the rear mount. lower the trans (best to have removed the rad or at least have someone keep an eye on it so as the engine tilts back you do not have a fan blade dig into the rad core), until you can clearly see the shifter pin. You will have enough room to get in there with a pick and remove the circlip, pull the pin, pull up from the inside of the car the shifter, and get it secured so it does not impede the rest of the work.

installing a trans with the engine in is a hit or miss prob as far as the hassle of getting the input spline to align with the clutch plate. I like to use some long bolts with the heads cut off as guide pins (I cut slots in the top to allow for a screw driver to be use to remove the bolt once trans is fitted), one on the top and one on the bottom opposite side. This lets you get the trans clocked right and in the general position. from there it's a lot of wiggle, push, swear words, then pop it just goes in. Sometimes you get lucky and it just goes in and you wonder what everybody it talking about it being a PITA.

A tip is to put the trans in gear before removing the shifter, this will allow you to twist the output shaft by hand while doing the wiggle/push motion. The idea being IF your spline is just off a hair it may help it align. In reality the guide pins should be sloppy enough to let you twist the entire trans, but if the input shaft is binding up on the clutch and not in the perfect position it may resist moving to align. Being in gear gives you a bit more control over the ablity to align the input shaft.

another tip, when tightening the pressure plate make darn sure the clutch alignment tool is going in straight. I can droop a bit from the weight of the friction plate. You should try to aim for a neutral position between the up and down amount of play even with the tool installed. Make sure as you go the tool can be inserted and removed easy.

I have done this a few times, like I said sometimes it just pops in so easy you wonder what is the big deal, other times not so much.

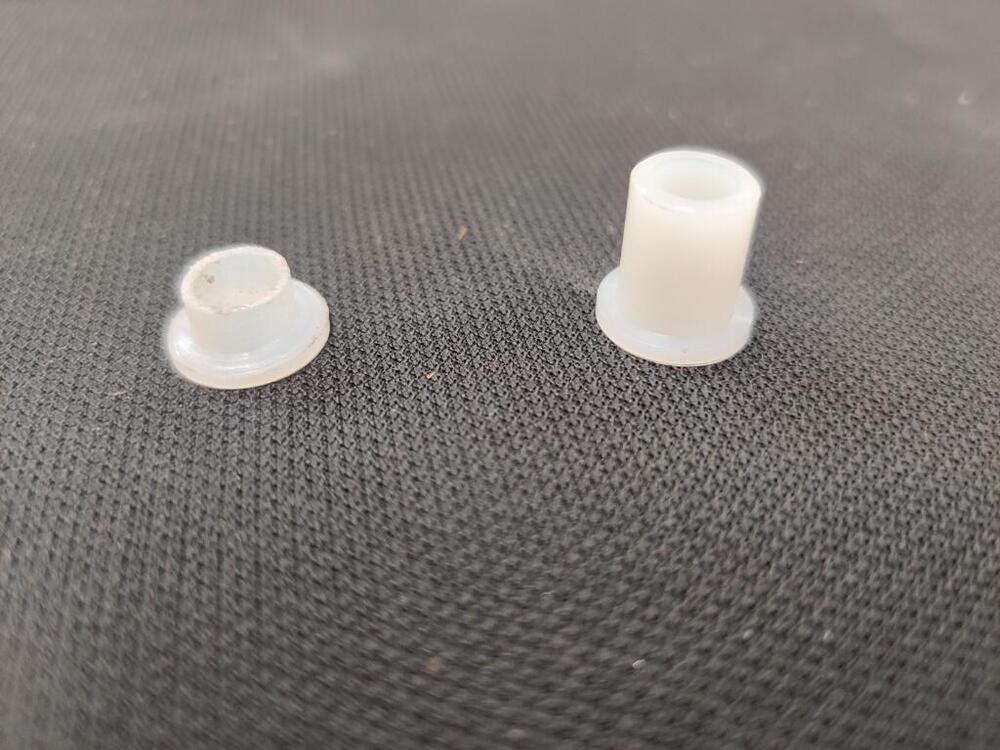

last tip, make sure the alignment dowels are in place, these keep the trans input shaft perfectly centered, there are 2 diag mounted I cant recall if they go in the block or the trans housing. The fit OVER the bolts in enlarged holes, so the bolts go thru them.