Gents, I wanted to get on here and let you all know briefly why I’ve been gone and that I’m back.

I’ll keep it brief and if you want to more details send me a message. About 8-9 months ago I had a medical incident that was a wake up call for me. It ended up with my in the ER with a doctor standing over me with cardiac paddles telling me they’re going to have to smock me.

My job is 100% contingent on my health. Shortly after I notified the company I was placed on medical hold, and have been in this status until recently. This medical event was a watershed moment for me and I spent some time reflecting on my lifestyle and then came up with a game plan. I determined it was time to “Reset my life”. I had to reevaluate all my actions that impact me and make changes. This medical event opened up a host of other boxes with the FAA drilling down into every medical aspect of me. I had many doctors visits, saw specialists and found I had some blood work items out of normal ranges too. I had to do a couple sleep studies and so on. It was painful! It didn’t help I ran into incompetent people along the way which made me realize how broken our medial system is. I can dive into that later but because of incompetence and financial incentives by secondary medical providers who were calling themselves “experts” I was going to have to do treatment I didn’t need or want,

So I had to become my own advocate and spent countless hours researching and educating myself. I read several book by “real” experts and had great advice from friends who are physicians. I became a pseudo expert is some medical areas and with the actions I implemented I turned everything around, I’d go see my doctor and we’d discuss items that he really knew nothing about. I was shocked at how our medical system works and how it is incentivized.

So what did I do to reset my life. I changed everything; my Diet, Exercise, Nutrition , Sleep, and Stress; it all had to be changed. Because I didn’t have time to figure out exactly what I needed to do I used the “cast a wide net approach”. Do it all and hopefully i fix these issues. This ultimately worked, it wasn’t easy. I had to be disciplined and methodical and I was. In this time, I’ve lost 24 pounds, ( I wasn’t really heavy to begin with), I exercise for 60-90 mins 5 days a week (running 15-20 miles a week), taking multiple vitamins and supplements, track my sleep and O2 saturation every night, and removed all stressful activities I can. I stopped drinking alcohol, removed all sugar from my diet, The second order effects are many. First I feel better than I did 10 years ago, I’m never tired, I have more mental clarity, I dropped my LDL cholesterol 70 pts without medication, blood work is now normal, I sleep great.

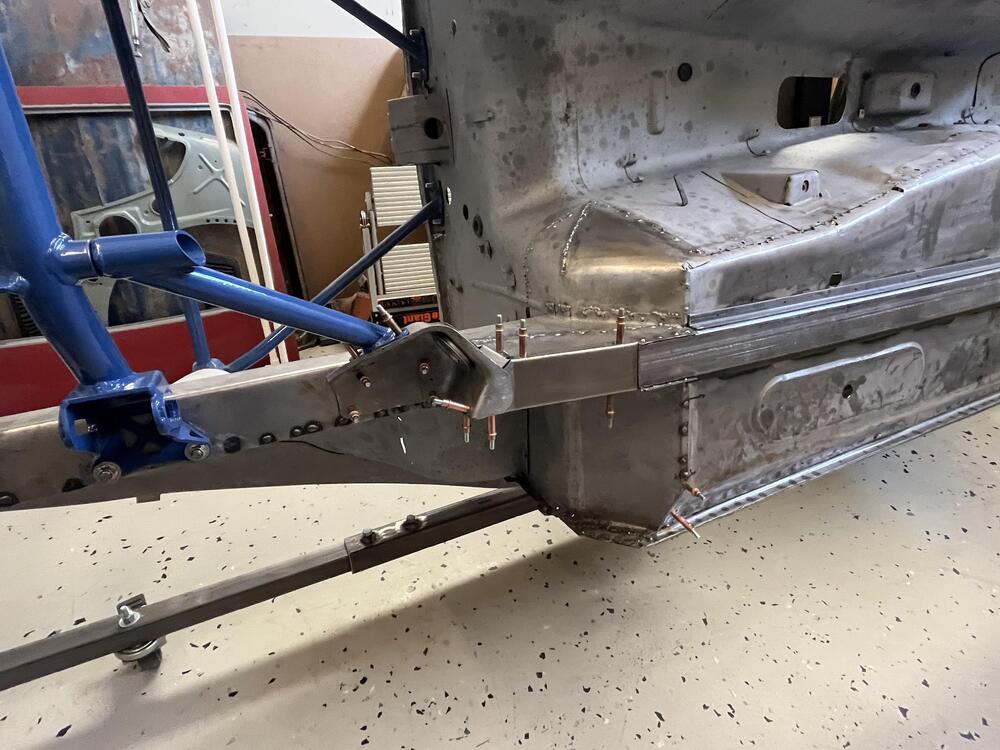

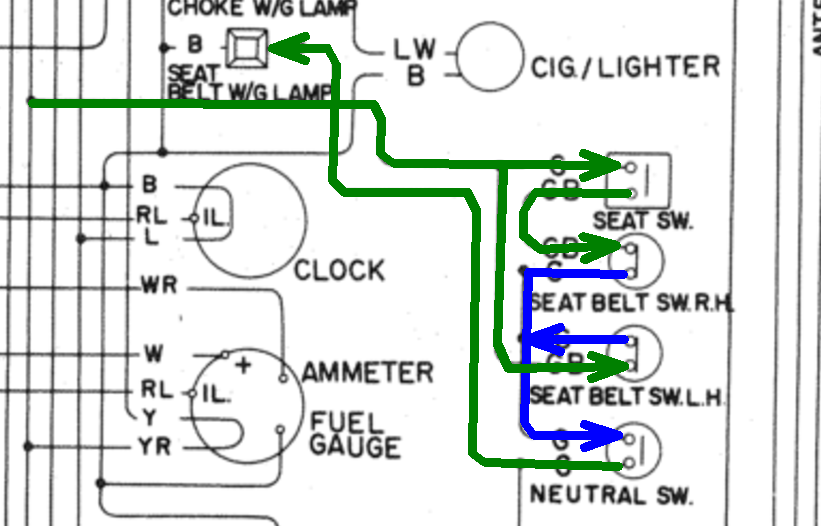

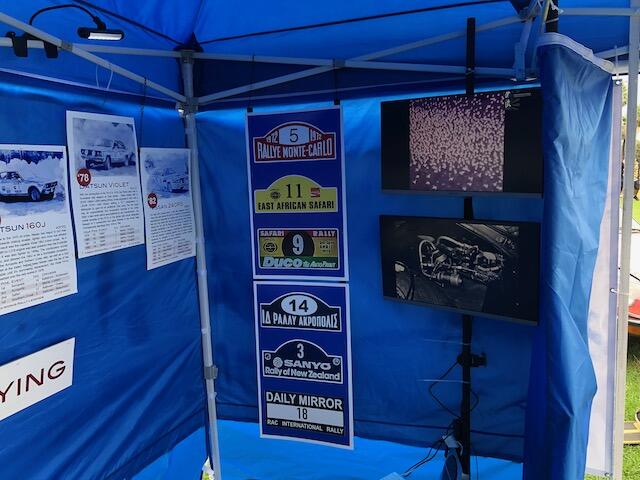

I stopped working on my car during this time for the most part. I did a little here and there but it hasn’t had anything really done to it. I do drive it now and then. I had to refocus my life and that meant 100% commitment to the things I determined were more important after evaluating everything. The tenants were: Family, Faith, Friendships, Spiritual and Mental Heath and overall personal Wellness. Everything else was placed on hold.

The bottoms line is this long post is I’m back, I’m better, I’m going back to work in 2 weeks. This event was a blessing in disguise. That’s my story!

Subscriber

Subscriber 6Points428Posts

6Points428Posts