“We got to run on heavy, heavy fuel…”

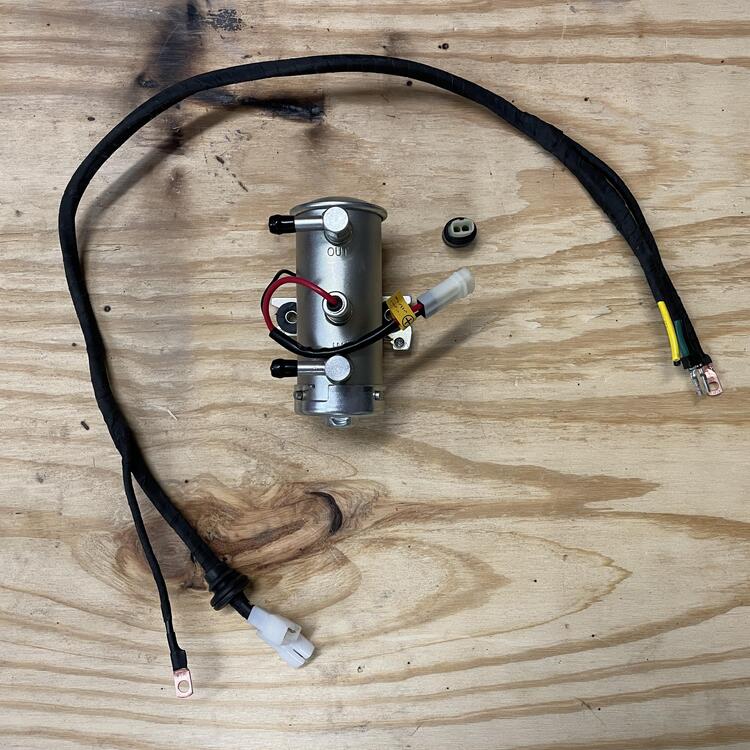

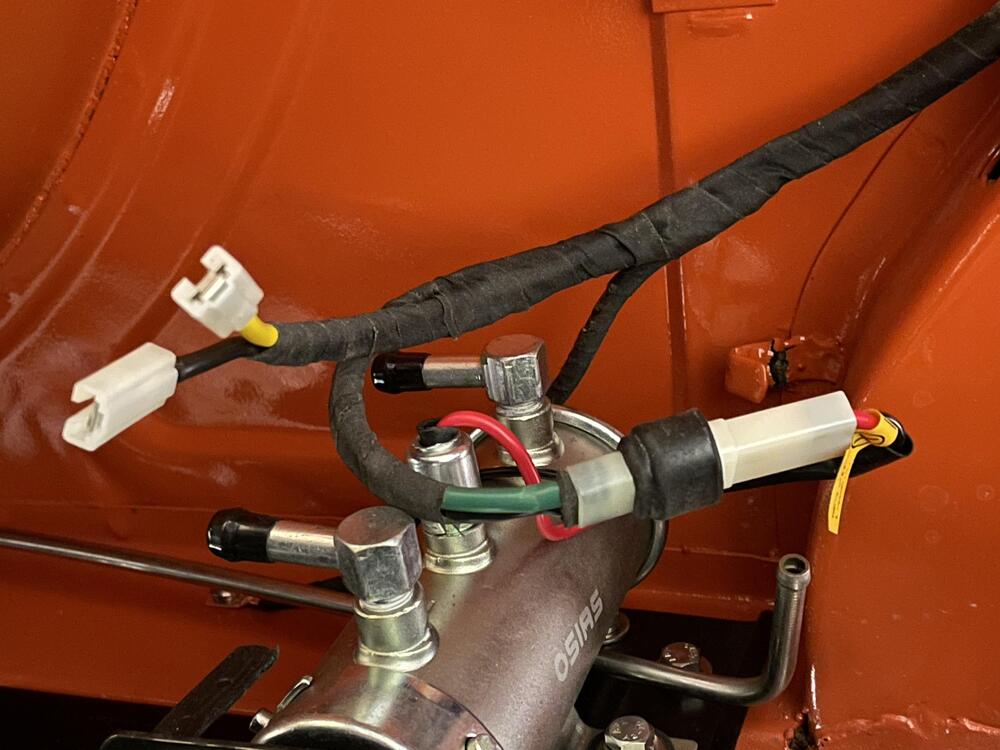

The gas tank is in, the vapor tank is in, all the fuel lines are clamped down, the filler neck and cap are in, the pump and sending unit are wired up, and the system is closed from the hard lines back.

I got hung up because I forgot to refurbish the straps, so that knocked a day out while paint dried. I also never found the right filter bracket, so I picked up a shiny new one for a Suzuki outboard motor that holds the OEM Nissan filter perfectly.

The only things I’m a little unsure about are the straps being less tight than before because the stainless Z Car Garage hooks don’t tighten as far as the OEM ones, and not having rubber boots on the sending unit wires. The plastic connectors don’t cover the nail terminals as well as I expected so I may need to make them more weather proof.

No, I didn’t go with e85+ hoses. I struggled to find the right sizes in lengths shorter than 50 feet and got tired of holding up the project, so old school FTW. I did use modern stainless steel strap clamps, though, because I’ve read they provide a better seal than those OEM Nissan wire clamps.

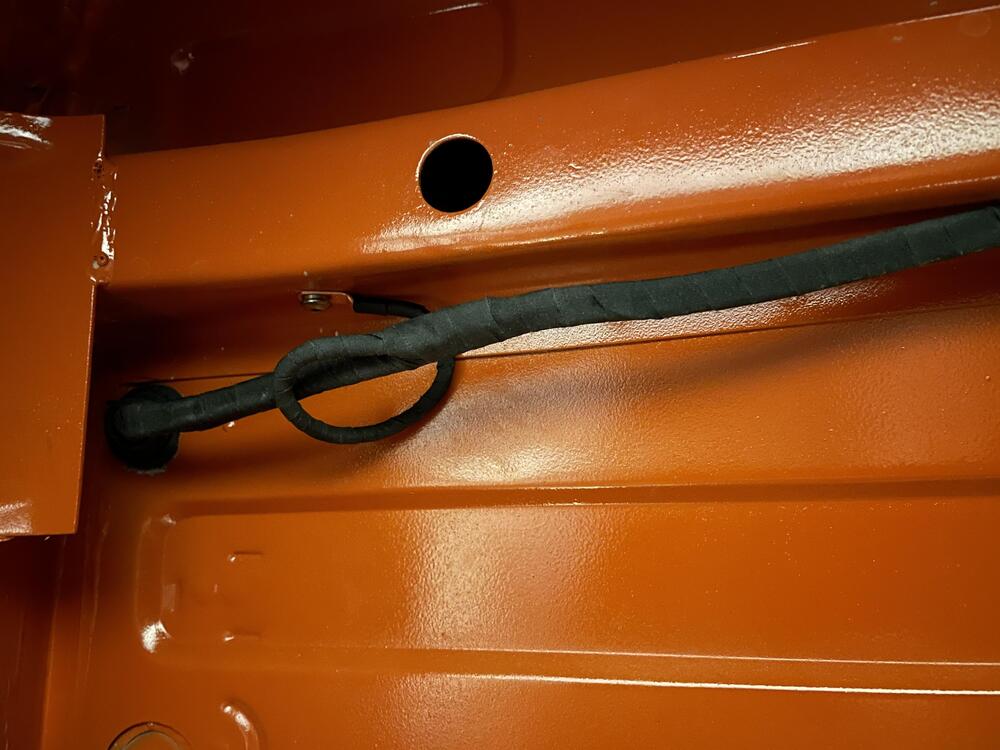

All the braided hoses came from JBugs California Pacific and are metric. The 12mm hose was the only troublesome one because the metal tubes want something more like 13 to 15 mm, but the 5, 7, 9, and 17 were perfect. The vapor tank hose with the shepherd’s hook bend you can still buy is 12mm also, so I guess we just have to struggle with that.

So yeah, I can technically put gas in the car now. ⛽️