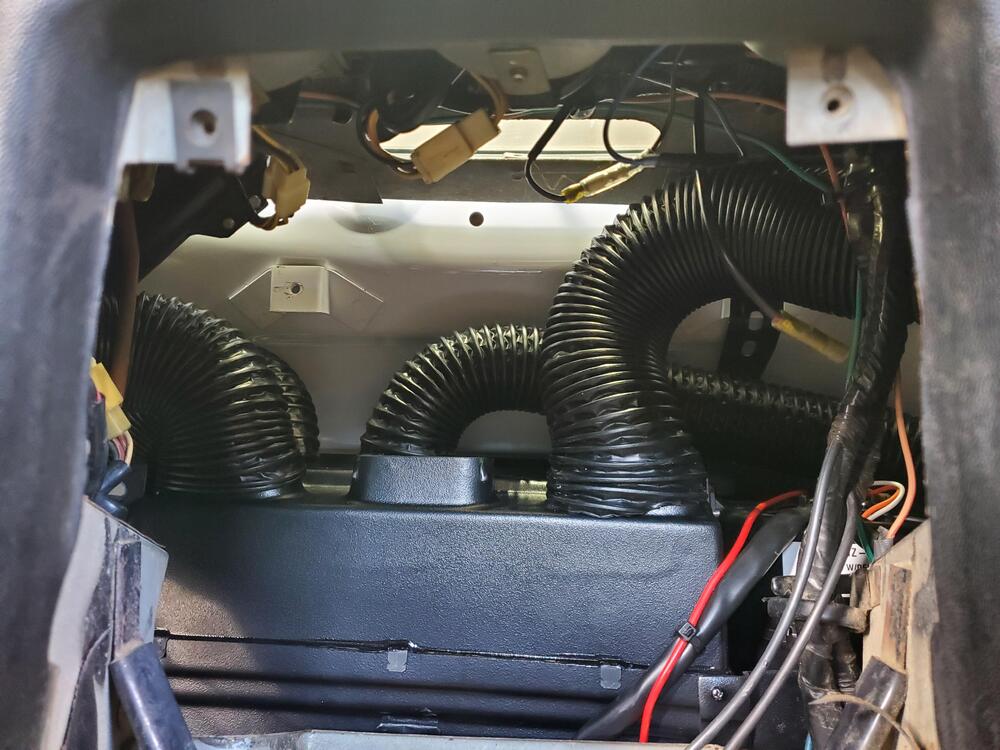

Haven't posted in while but got a lot done. I installed the dash and hooked up the ducts from the VintageAir system. This was pretty easy. Vintage air sends two diameters of tubing with their kit. The smaller diameter hose is for the defrost ducts. Amazingly, the small diameter hose fits perfectly on to the stock defroster vents. A small S shaped section does the trick for the defrost attachment. The Outside vents are also pretty straight forward. I installed the larger ducting in the dash and left the hose long in the middle. After installing the dash, I trimmed the hose and connected it to the Evaporator unit two outside ports. The center port on the vintage air system is for the 'floor', however, I will fab something so that it can come out of the center panel. The lower switch in the front control panel gives you 4 options: Off, Vents, Floor and Vents+Floor. All electronically controlled. Very nice. So, AC mechanical system is now completely installed including a belt for the AC compressor. I will connect the final electrical when i install the panel. We will charge the system at a shop on a later date.

Installed a fused switch for the fuel pump. This is right in front on the dash for easy access and operates nicely.

Got the rear interior panels mostly installed. Panels were from a different car, so most of the holes lined up (versus purchased panels where half the holes do not line up).

Installed a new removable steering wheel. This is actually pretty sweet and makes getting in and out of the car a bit easier with the flat bottom.

Installed an offset stick for the 5 speed transmission. The straight stick will not work when connecting to the 5 speed. Both sticks shown in Neutral position. Final install pics are with offset shifter ,shown below.

We started the engine up and she sounds great and very smooth. The clutch system bled nicely and operates well. Fluid was put in the transmission as well. Once I get the brakes ironed out she will be ready for a cruise around the block. My initial bleed did not go too well. I could not bleed the forward bowl on the Willwood master cylinder from the forward bleed port, so will have to investigate that.

Center console has a hole forward of the choke lever. I will be installing a USB port in this position.

Latest pics are below

Subscriber

Subscriber 3Points2,228Posts

3Points2,228Posts