OK - so finally had the time & break in the weather to swap out the coil & module.

I did first just plug in the HEI module with the stock coil & ballast, and as expected the tach functioned normally with the stock 2.2K ohm resistor.

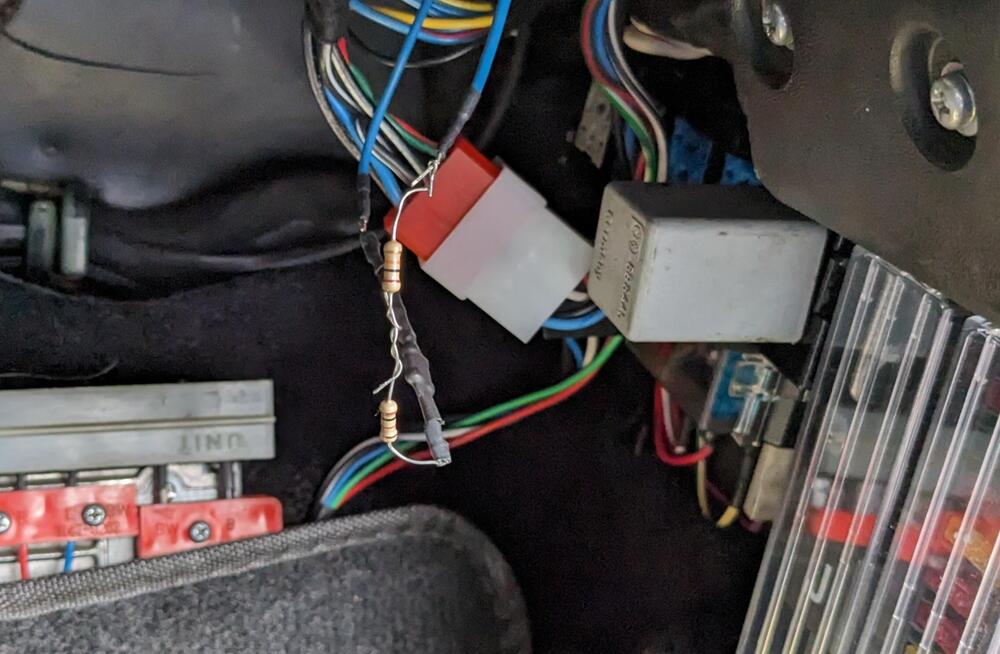

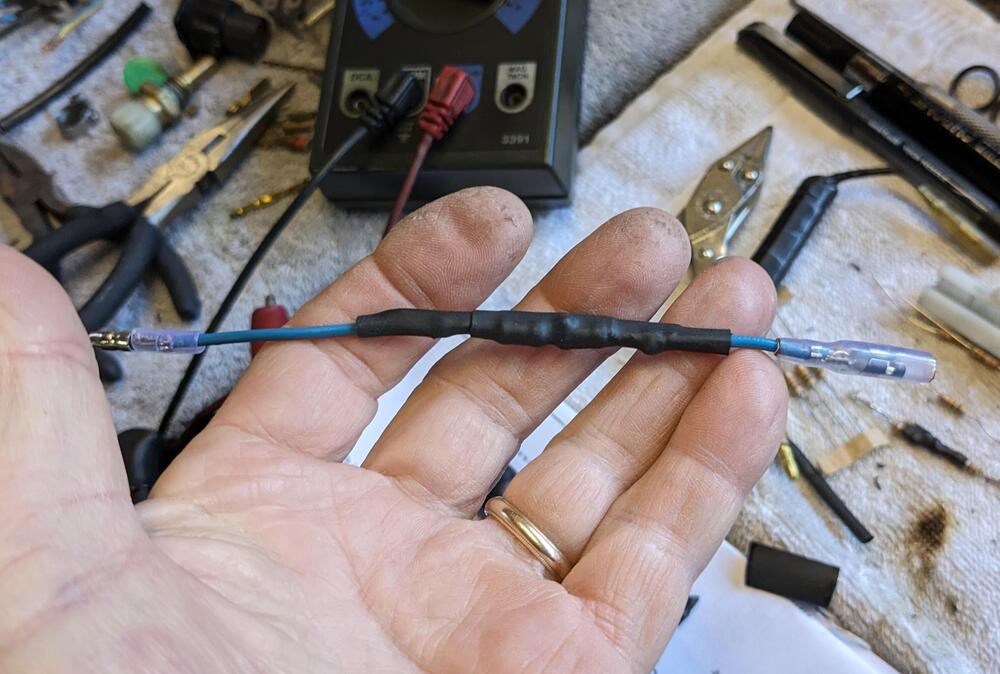

I swapped out the coil and ballast bridge, and tried the 5K ohm resistor bridge. Tach operated briefly, then dropped. I then added a 1K resistor in series with the 5K, and that was better, but tach was still erratic & dropped out after a bit. Added another 10K (9.8K actual, thought I was adding .5K ohm) and with that, the tach smoothed out, held normal idle rpm & revved freely in time with the engine. So, for me, 15800 ohms is the value required.

I drove the car to work this evening for my parent-teacher conferences, and I have noticed that there is a noticeable 'jerkiness' on throttle tip-in that is not present with the stock ignition setup. Not sure why that would be, I'll have to see if it persists. I also have not swapped out the generic Standard Motor Part module for the geniune GM module, so it is possible that is the culprit I suppose.

Used a 14.8K & 1K in series for the final resistor.