Thank you, it was indeed a bit of a hunt 🙂 I already started the assembly and it's so satisfying and fun.

A few days ago i got a call from my Panelbeater that they finally got the chassis out of storage again and re-started work on it. This time with two people. Nice!

Today i went over to have a look and discuss some next steps and details. Well the progress was much better than expected.

First i was greeted by a more or less complete upper front end body. Here you see the two masters in charge of my project.

They also proudly showed me their spot-welding machine when i asked how they weld some of the parts. I'm unfamiliar with spot welds but it is quite the machine 🙂

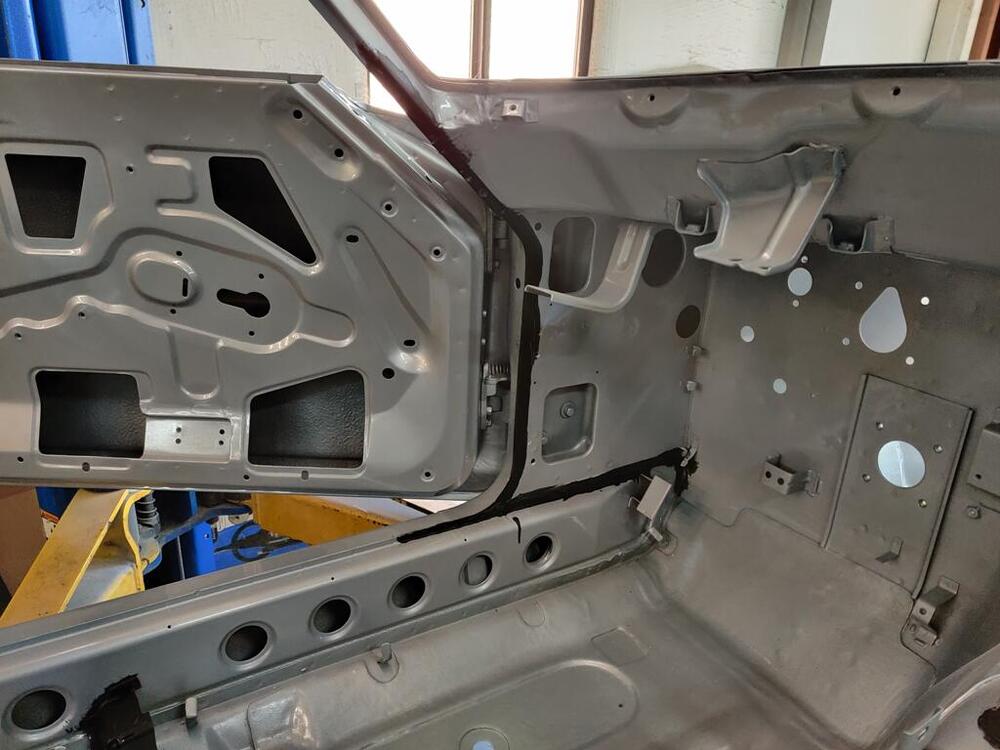

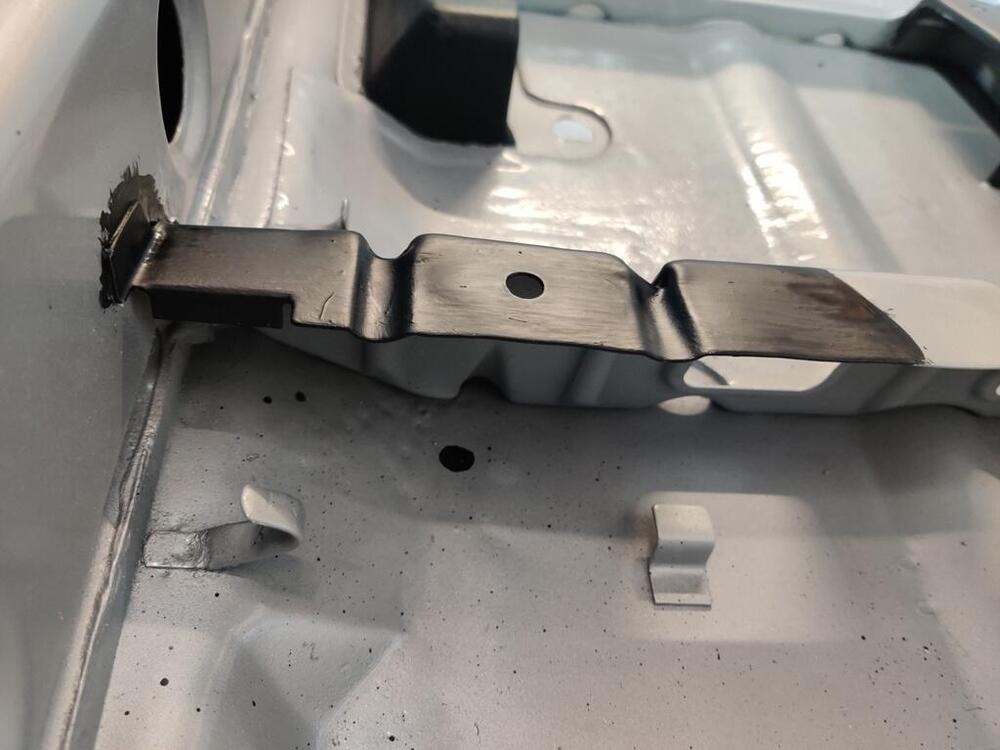

So what happened since my last visit? The right-hand floor pan and inner door sill has been completely replaced and the original seat rail mounts are in the proces of being reinstalled.

The bodyshop claimed that some of the welds from the previous bodyshop were not so good so he ended up ripping out everything in order to get it done professionally and replace the self-made panels with the spare KFV Panels i had given them for "just-in-case" requirements like this. While it is extra work and cost, i absolutely approve what they do and i'm more than happy i switched to these guys. True masters of their craft.

So the floor / Firewall / Front end section is more or less complete. except maybe for the RH outer side sill which is still under debate:

On the LH the KVF lower outer side sill has been modified to fit (still needs some adjustments). What is left missing is the line in the door, which some of the previous owners thought was cool to "shave", so they have to hammer it back in.

The roof skin (which was full of small hammer-dents due to a previous damage / repair) is meanwhile also repaired (i wasn't able to see it today, as it was in storage), so after they adjust and finalize all the small details, there are mainly three big tasks:

- Fit the rollbar

- Replace the LH Rear quarter (and inner wheel well)

- Replace the roof skin.

Of course there is also hours of detailed adjustments and a chassis-alignment scheduled, and primering of all uncoated surfaces to prevent rust.

I have to bring them some parts in two weeks to proceed, until then i'm on a business trip and i really hope they keep up the pace until my return.

There is also a new timeline due to various delays and another big (bentley) project, so the body should be ready in Q2 next year. Fingers crossed...

Oh, and a bit off topic, but i also managed to find a NOS 240K-GT (Aka GC110 Kenmary skyline) Radiator and Hose at a very old radiator shop in switzerland, which will now be used in my mate Stefan's Datsun 240K-GT Restauration.

Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts Subscriber

Subscriber 3Points2,733Posts

3Points2,733Posts