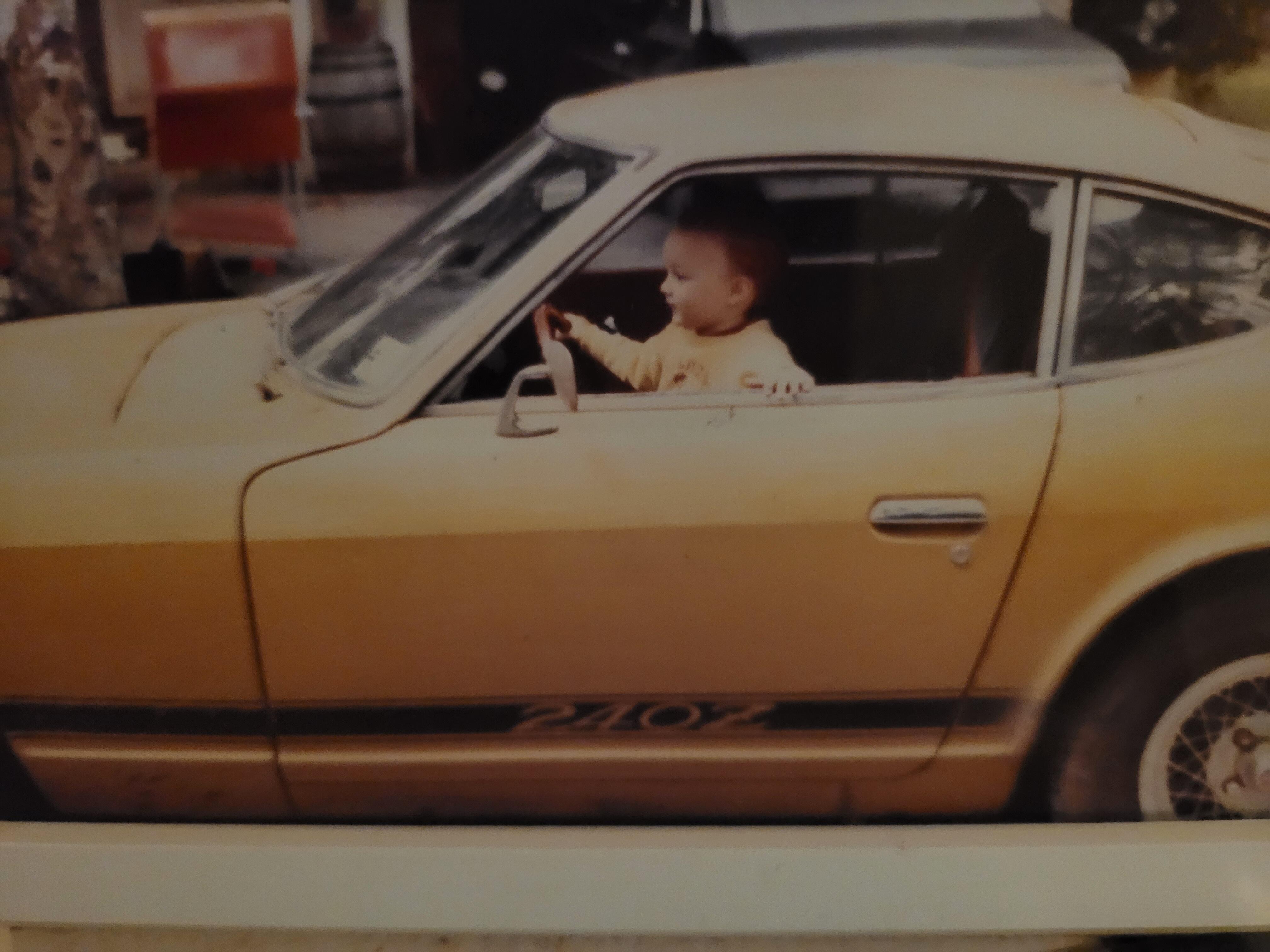

So today marked a huge milestone - I was able to fix my ongoing, intermittent hesitation and poor operation of my 280Z! Many thanks to a lot of help from my new friends on this forum and a lot of persistent troubleshooting and eventual replacement of suspect components. As it turned out, my ignition coil was bad - when I tested the resistance, I was getting high and inconsistent values. I also ended up swapping out the TIU with an HEI module. The final step was bypassing the resistor and connecting directly to the coil. Now the question is what to do with the replaced and not reinstalled parts? Maybe I will make a museum of my old car parts. What started as a joke, I saved the idler pulley bearing that self-destructed and destroyed my timing belt in my 1986 Toyota Camry back when I was a poor college student. I also saved a few of the broken lug nuts and stripped lug studs from my current WRX (don't get me started on these, it's an ongoing QC issue every time that swap my summer and winter wheels. I am convinced Subaru used low grade, crappy aluminum lug studs as a cost saving measure and failed to instruct their dealer technicians to not to use air wrenches when rotating the tires or they could strip out the lugs. Maybe I will finally be rid of this problem when I have replaced each and every one of the lug studs.). I have never had this problem with any other car, present company (2017 Sienna, 1976 280Z) included, as well as previous Subarus. Ugh.

I also went on a few drives. The first was around the neighborhood with my son and daughter, who both seem to love the car and were overjoyed that I fixed it and Samus is in running condition again. The second was to Detail Garage to inquire about the current condition of the paint and what I can do to restore it, if anything. My main concerns are these spots and the few areas where the paint is cracking and peeling away. I initially thought maybe the spots were due to one of the PO's parking under a sappy tree and never bothering to clean it off. However, after some examination, it looks like the repaint job that the second owner performed may have been as described by the seller (3rd PO) as "not really a great job." The Detail Garage pros seem to think that the spotting may be a result of a chemical reaction that occurred during the repaint because the spots do not appear to be on the top surface of the paint. They also did not think the paint was as in dire condition as I originally thought, and suggested that I wash and wax it and it should come back considerably. A good waxing should also protect it from further damage until I repaint in the future.

I'm probably preaching to the choir here, but when this car is running right, it is an awesome driving experience that has been lost with modern cars. I know it's not as fast as my WRX, or my previously owned 370Z, but driving the 280Z is a much more engaging experience. When you floor it, the 280Z responds and moves with a sense of urgency. The newer cars seem to accelerate too smoothly and you don't feel it. Maybe they are too insulated from the road? Bigger and heavier? The WRX looks like an SUV when parked next to the 280Z. What an experience behind the wheel of the 280Z. I can't wait to take Samus to a car show. The amount of attention I get when behind the wheel is pretty cool - I get a lot of thumbs up and stoplight conversations of people telling me how much they love the car or have a Z story/experience of their own. Ahh, the joys of owning a classic.

I can't wait to get behind the wheel again, maybe tomorrow.

Subscriber

Subscriber 6Points107Posts

6Points107Posts