I am still rounding up hardware to prep and have re-plated. That quest led me to the starter. I forgot to take pictures of the state it was in, but basically, the plating on the starter and solenoid looked like it was mostly gone, surface rust, light corrosion, etc. It was functional, as it started the car before I removed it.

I can find remanufactured starters for around $50 delivered. However, it is a bit of a guessing game as to whether the starter will come with the same parts plated as the factory did. And remanufactured starters are not all remanufactured the same way - some are lower quality, some are higher.

After doing some searching, I determined that bushings are available for the front and rear of the commutator. I took some measurements of my starter components and compared them with the factory specs in the workshop manual. Still trying to determine which way to go (rebuild mine, or go with a remanufactured unit), my decision came down to the fact that I could not figure out how to get the solenoid case off (to re-

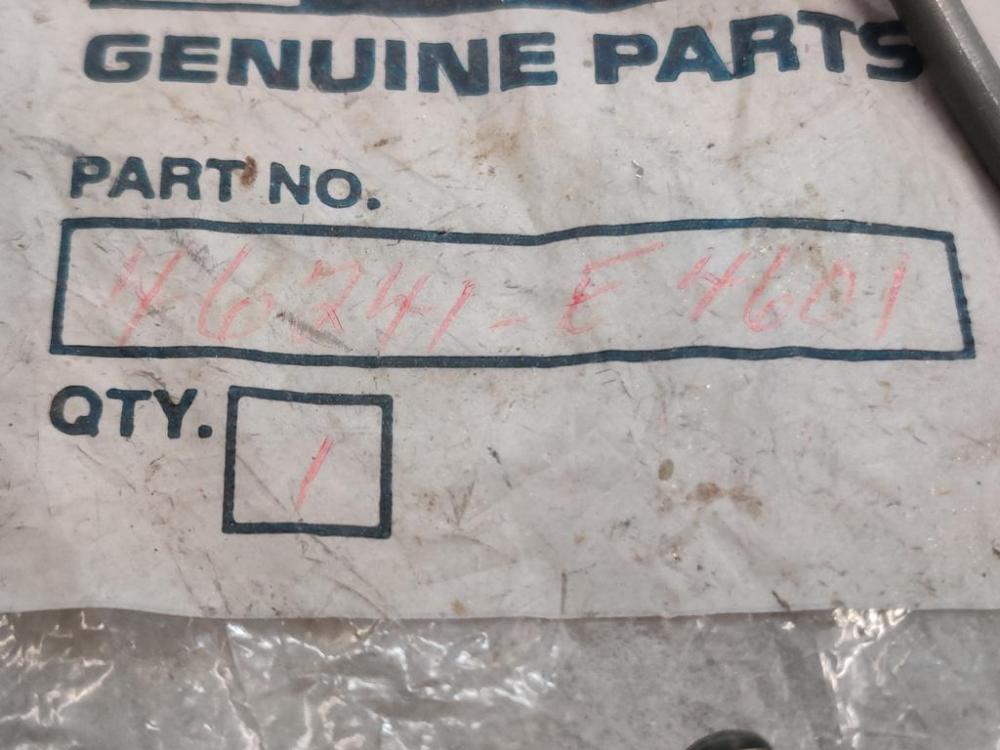

plate it). I was about to go with remanufactured when I dimly recalled having purchased an OEM solenoid many years before (like more than 30) for my 510 that I never used.

So, after finding this in one of my 510 parts boxes:

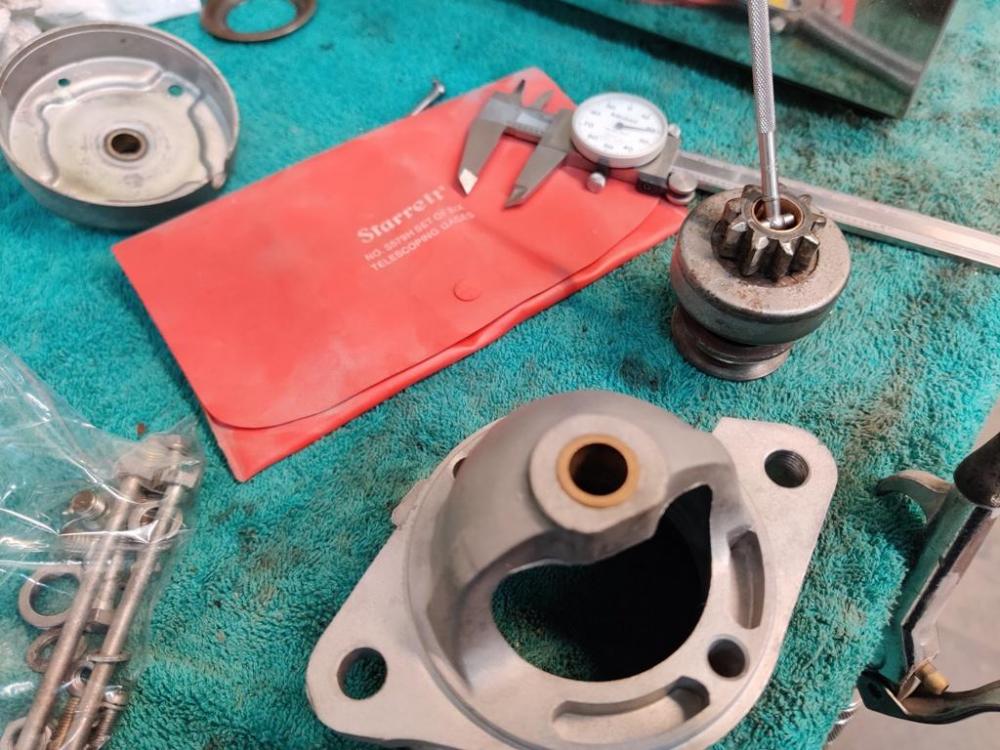

I decided to rebuild my starter. Pics of tear down:

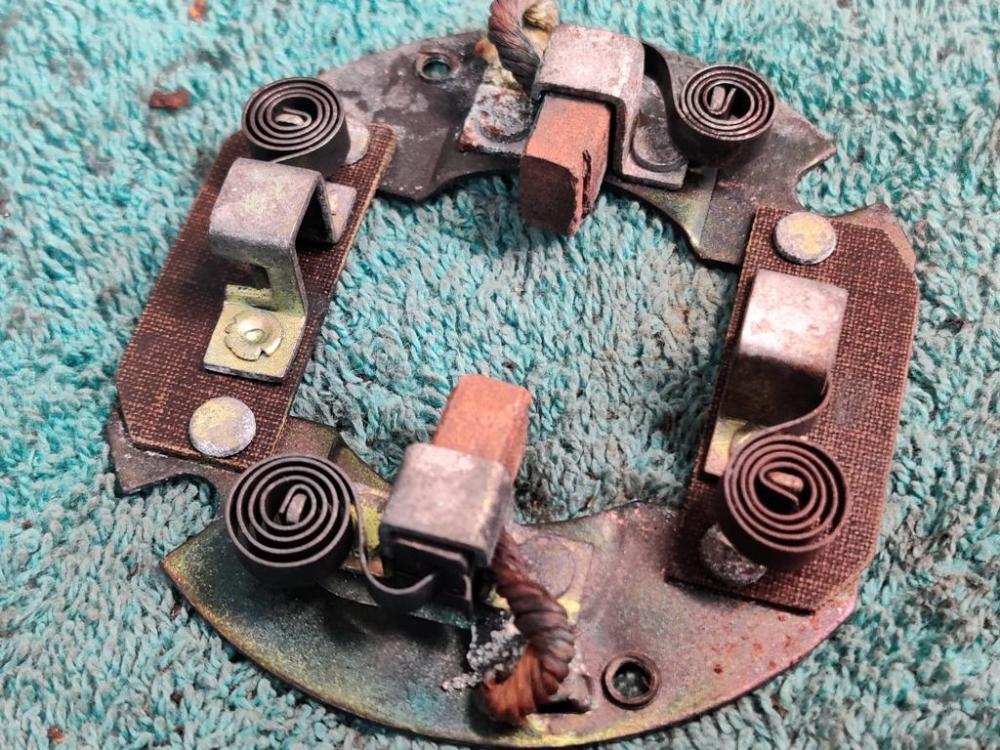

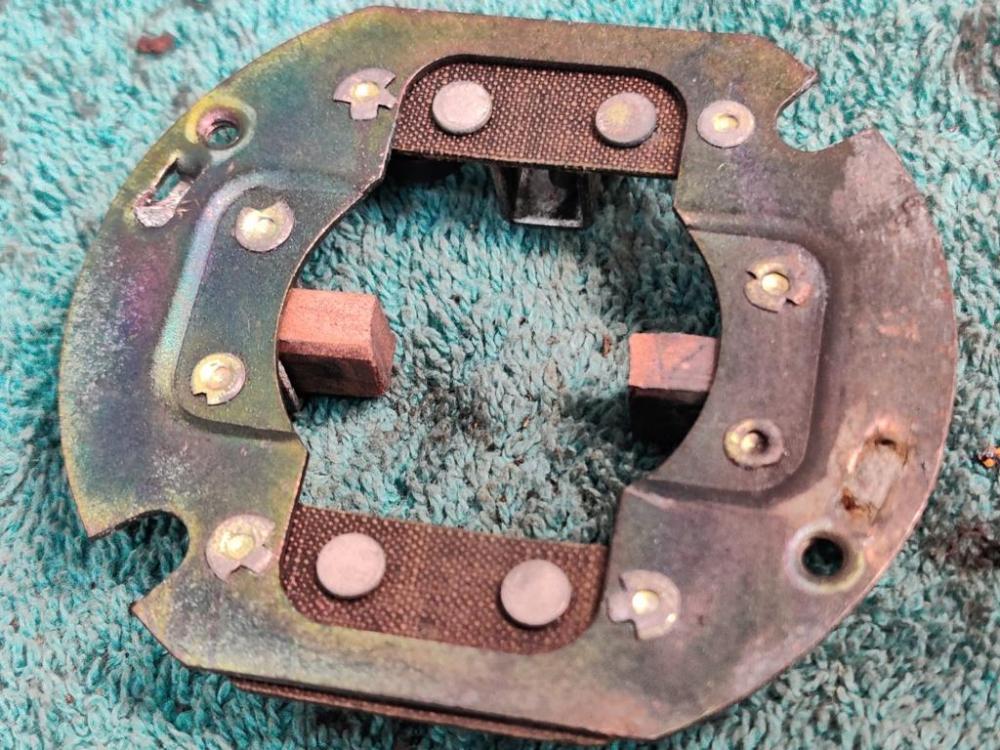

After tear down, I put most of the parts in an ultrasonic cleaner:

The brush holder came out nice:

I glass bead blasted some of the parts (front cover, hardware, rear aluminum housing, steel housing)

Some slight corrosion on the steel casing where the rubber grommet goes. Front cover before glass bead blasting:

Starter drive (gear and clutch) looks pretty good overall and functions properly. Armature seems ok (measures within spec and shaft ends are within spec)

Further glass beading of the front cover gave a more uniform finish. In the last picture, in addition to the glass beading, I took a piece of very fine steel wool to put a bit more shine on the surface.

Next, I will have to order the bushings, and do the work to replace the old ones and size them to fit properly.

Subscriber

Subscriber 9Points3,770Posts

9Points3,770Posts

Subscriber

Subscriber 4Points2,734Posts

4Points2,734Posts