So the recent chatter about timing and distributers has me thinking.

The stock distributors include a mechanical (centripetal) advance function and the spec varied some over the years, but as an example here's the spec for 77:

0 degrees at 600 distributor RPM (1200 RPM at the crank)

8.5 degrees at 1250 distributor RPM (2500 crank)

There should be no mechanical advance below 1200 RPM, then start ramping up to a max of 8.5 degrees by the time you reach 2500 RPM. Once above 2500 RPM the mechanical advance is topped out and holds at 8.5 degrees all the way up to redline.

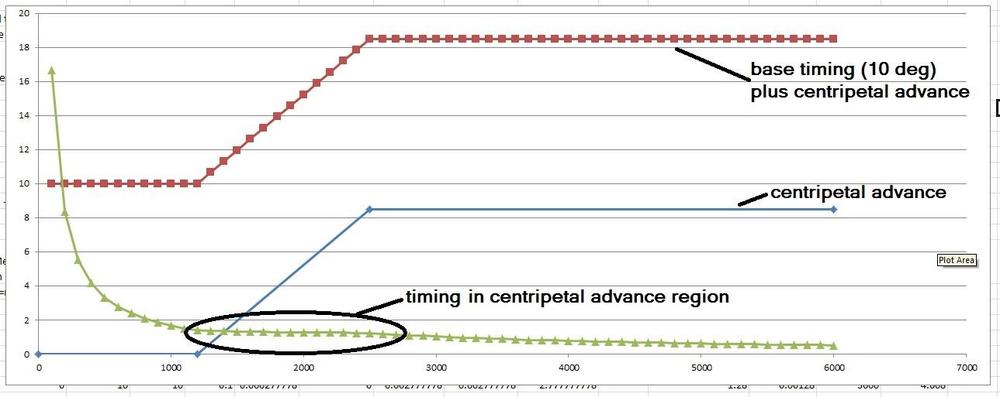

Specs like this are given in degrees because that's what can be measured and that's what you can see with a timing light. But if you convert the timing specs from the angular domain (degrees) over to the time domain (seconds), it looks like this:

At 1200 RPM, the engine is spinning at 20 rotations per second.

At 20 rotations per second, each rotation takes 50 milliseconds.

If each rotation takes 50 milliseconds, each degree of rotation (out of 360) takes 139 microseconds.

So at 1200 RPM, the 10 degrees of base advance provide about 1.4 ms of advance.

Doing similar math, if the engine is spinning at 2500 RPM, then each degree of rotation takes 67 microseconds. The 18.5 degrees of advance (10 base + 8.5 centripetal) provides about 1.23 ms.

If you go through all the math and plot the results, you come up with something like the following. Notice that the advance value where the centripetal advance is active is relatively flat, but then the advance falls off above that once the mechanical advance has topped out:

Studying the numbers, I come up with a relatively constant average of about 1.2- 1.4 milliseconds of advance in the centripetal advance region.

So my question is.... Why didn't they continue to advance the centripetal timing above 2500 RPM? Is that just a limitation of the mechanical functioning of the distributor? They just couldn't get the springs, weights, slots, etc to swing a wider range all the way up to redline? Isn't necessary for some reason? Or wished they could have, but just couldn't come up with a cheap enough way to do it?

Subscriber

Subscriber 4Points2,733Posts

4Points2,733Posts Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts