Everything posted by Namerow

-

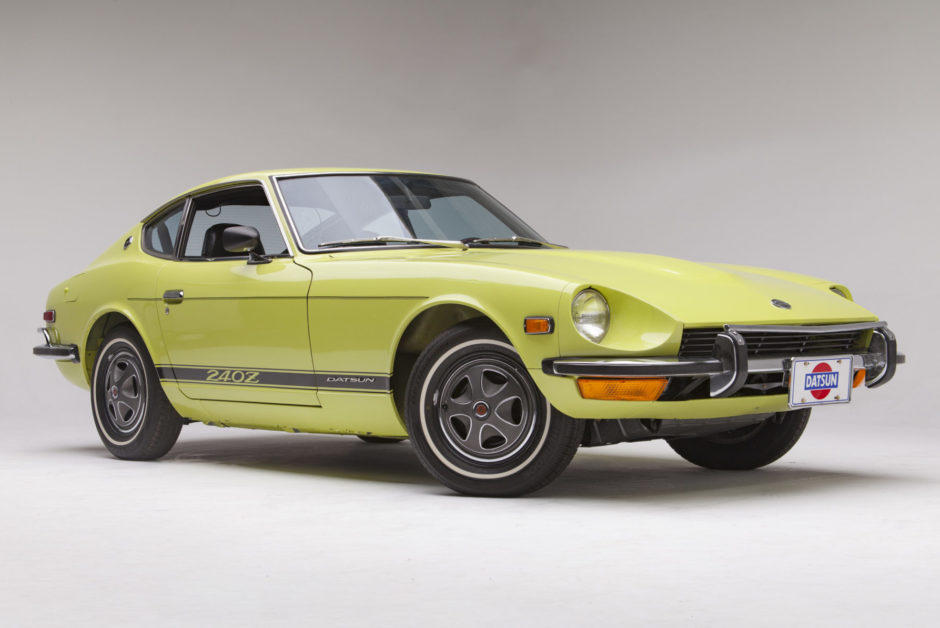

73 Z brings $52,500 on BaT

Unquestionably a nice example (and very professionally presented), so deserving of a premium price. Still, it's a 73, where prevailing wisdom (now obsolete?) has said that these should be discounted relative to the 70-71 models. Overall, I think we're seeing a solid trend towards 'good' Z's moving up in value by $5K - $10K compared to a year ago. https://bringatrailer.com/listing/1973-datsun-240z-91/

-

HLS30-00512 up for Auction on BaT

Per the commentary on BaT, I certainly see how the rear valence panel is distorted (and the bumper isn't aligned and the hatch sits a little high on one side). However, I'm having trouble finding the distortion that's said to have occurred in the rear deck . It is too bad that it's not a matching-numbers engine. Matters a lot to the high-end collectors. Shifter location in the console opening suggests that at least it's got the correct 'A' 4-speed (original?) Overall, there's a lot to like about this car. Even the floors look not too bad. The dash will need attention, but the collectors didn't seem too bothered about the dash cap and the dash recover on a couple of recent high-$ Z auction cars. Hard to say these days whether an uncracked dash really commands a premium in an otherwise-desirable Z.

-

Alternative Brake Vacuum Hose Source?

Thanks for blazing the trail. I may give this a try with some straight braided hose that I have on hand. The early-style engine-side brake vacuum hose is a hard item to find.

-

tres cool

Graphic illustration of why flatheads aren't very efficient.

-

Need a hood fast

If you are willing to cross the border, there is a gentleman in the west Montreal region who has a significant collection of S30 body panels. I do not know if he is set up to ship (or is interested). PM me if you want contact details.

-

Datsun-240z Vs Fairlady-z432

I don't think the Z seats ever got the credit they really deserved for their styling. Maybe not so excellent from a functional or comfort perspective, but really great to look at and perfectly in tune with the exterior styling.

-

QuickJack BL-5000SLX - $1099 at HomeDepot Online

The 5000-lb unit is available in Canada from either Costco (Cdn $1350) or Canadian Tire (Cdn $1500). Unfortunately, no retailer seems to want to stock the 3500-lb unit. It should sell for about $150 less than the 5000-lb unit. The Canadian distributor for QuickJack is located in Mississauga, with a secondary outlet in Surrey, BC.

-

Hs30-00019

Nice shot. Don't forget to take a matching, 'After' picture when the car is finished.

-

78 door alignment help

I always figured this came from using the window frame ('sash') as the pull (or push) point for closing the door. Maybe, though, it's just because of the impact loads when window frame meets weatherstrip at high speed.

-

A new tool for your shop: Ingersoll-Rand Cordless recip saw

I've been doing a bit of research on recip saws and came across a review of a (relatively) new product entry by Ingersoll-Rand. It's a cordless mini (0.55" stroke) targeted specifically for the auto body repair industry... One of its primary attractions is the ability to make relatively tight-radius curved cuts. It comes with a six 'extra-coarse' 4" blades (3 x 14 tpi + 3 x 18 tpi), rated for thick-ish sheet metal gauges, along with with two 12V Li-ion batteries and a charger stand. The blades may use a proprietary locking design (I've found conflicting reports on this) but, in any case, I-R offers a variety of replacement blade sets, including a 6-pack of 32tpi blades. This looks a lot more versatile than a die grinder or a standard-size recip. It also makes it unnecessary to have a power-tool-sized compressed-air system. A possible drawback, compared with a mini air saw, is that it measures about 12" in length. Weight is 2 lb. Batteries are said to be good for about '1 hour' of use. The manufacturer's webpage can be found here: https://www.ingersollrandproducts.com/en-us/power-tools/products/air-cutting-tools/12v-recip-saw.html A very informative independent review by a restoration shop owner (including a nice video of the saw in action) can be found here: https://shoptoolreviews.com/woodworking/handheld-tools/12v-ingersoll-rand-cordless-reciprocating-saw/ The kit (saw, batteries & charger, carry case) goes for ~ US $220. For my Canadian friends, I've found it available from an authorized Toronto supplier for Cdn $250. Comments welcomed.

- Calling all engineers

-

Jack Pad Adapter

You're probably right.

-

Jack Pad Adapter

Please explain your process (steps) for getting the whole car up on axle stands when using the pinchweld strips as the jacking point.

-

Seat Belt Bolts

The plastic nuts are spacers, used to 'adjust' the height of the seat. The one on the top in your picture is in use for this purpose. The one on the bottom is a spare that could -- if you wanted -- be moved to the top and doubled up with the one already there so as to raise the seat higher. The actual retaining nuts are pretty fiddly to remove (there's not much space available for wrench swing). If you've got one, a short ratcheting box-end wrench is the way to go.

-

sheared water pump bolts

Electric impact wrench worked first time for me. And the harmonic balancer/pulley slid off easily afterwards (no need to use a puller). Elsewhere: Although this may be too late to help you now, I had good luck with both the timing cover (and water pump) bolts by using a non-power impact tool (the type that you hit with a hammer). Worth considering if you have yet to start on the timing cover bolts.

-

Hello from across the pond! Searching for a 240z

Very nice work... but very pricey work. I visited Bradford many years ago for a meeting with the now-vanished Marsden Radiator Co. (swallowed up by Calsonic in the 1990's IIRC). Got lost afterwards while attempting to drive across the moors in the dark (cue Heathcliff).

-

Deal? Or No Deal?

Nice car. However, given that it's been repainted and refreshed (i.e. it's not 100% original), it will be interesting to see whether the bidding goes much higher than the current $60K. It's my impression that the extreme ($100K +) values are reserved for #1 condition, 100% original cars.

-

240z - fabbing new front rails

Your hand-scribbled notes in photo #1 say: 2" hole >> 2-1/2" male + 2-3/4" female. So, a few questions: It looks like the 2-3/4" die has a smaller wall thickness (1/16"?) than the other dies (1/8"?), so am I correct in assuming that this pair (2-3/4" with 2-1/2") was used -- after the 2" hole had been cut -- to roll the edge? What are the diameters for the the other two pairs of dies? It would seem that you would need only one additional die set (to punch the 2"hole). So why are there two other die sets? For the punch set, did you put any kind of bevel on the cutting surface of the male (or female) die? For the roll set, did you put any kind of contour on the contact surface of the male (or female) die? It appears that the straps welded across one face of each die were used so that a centering hole could be drilled. Even so, how did you centre the male die over the female die in the press?

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Deal? Or No Deal?

Considering the difficulties others have reported in accurately duplicating the horizontal 'crease' in the outer panel, these will probably same a lot of hours in final fitting. Are you planning to use them in the current project or will you save them for something else down the road? The photos of these pieces expose some details that are normally hidden from view and rarely seen in restoration photos. For example, what is the purpose of the tacked on stamping(s) located at the peak of the wheel arch on the driver-side panel? Interesting, too, that Nissan went to the expense of painting that circular black disc on the inside of the panel so the body colour wouldn't peek through the vent holes in the plastic trim panel. I guess they thought that looked cheap.

-

240z - fabbing new front rails

Thanks. That was at the low end of what I was expecting, so learning that they're available for only $0.56 is good news. Out of curiosity, I checked out the Eastwood Tools site. They offer a kit consisting of 10 clecos, 2 side clamps, and one set of pliers for $44. PAT's price (not even bundled as a kit) comes out to just $16.00 so this is definitely a supplier that I'll be adding to my 'preferred' list.

- 240z - fabbing new front rails

-

Size and type of rubber grommets on 1972 240z

- Size and type of rubber grommets on 1972 240z

If it's a 20mm hole, Banzai Motorsports were the only source when I last checked a couple of years ago. Things may have changed since then. Check the usual suppliers. If it's a 25mm hole, both Banzai and Motorsport Auto (and probably others) can help you out. - Size and type of rubber grommets on 1972 240z

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.