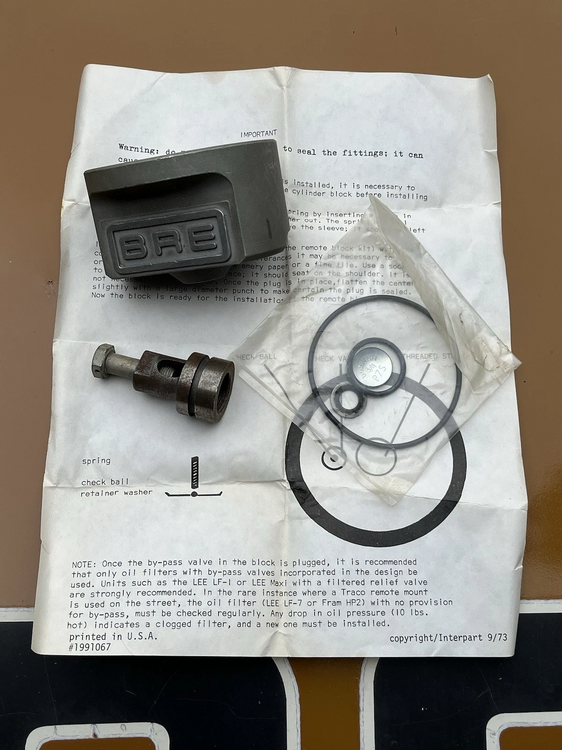

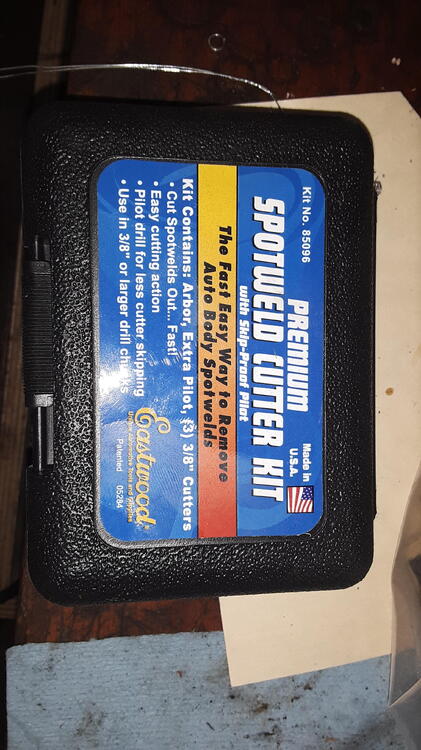

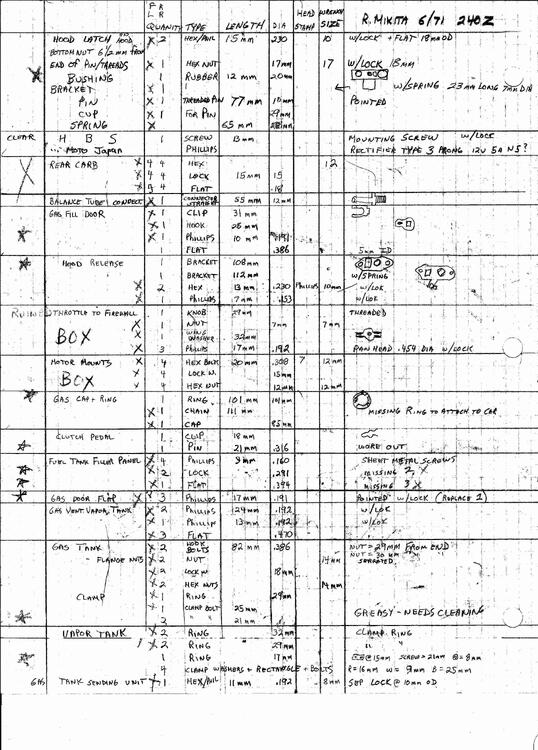

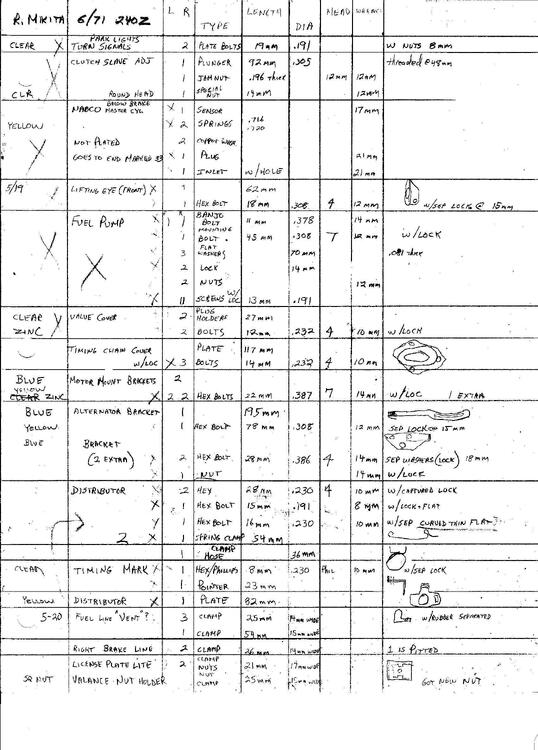

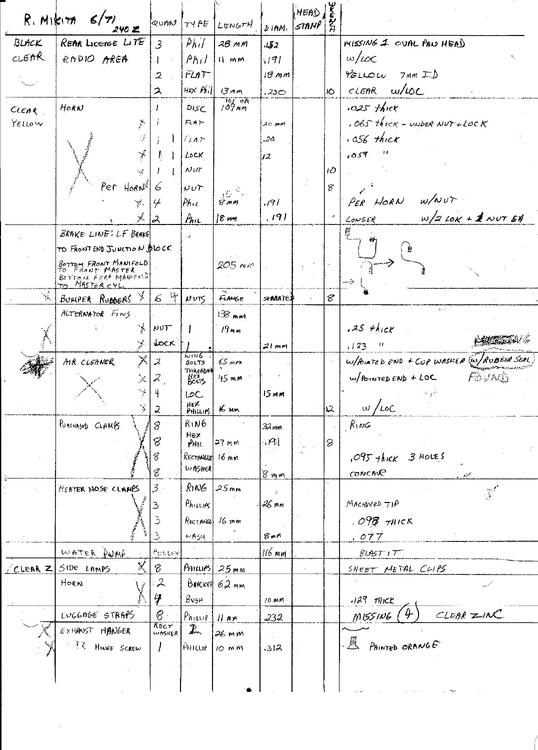

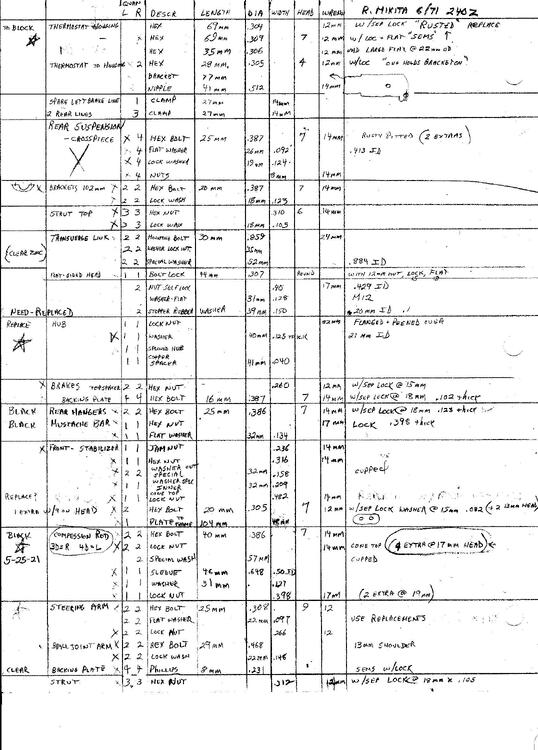

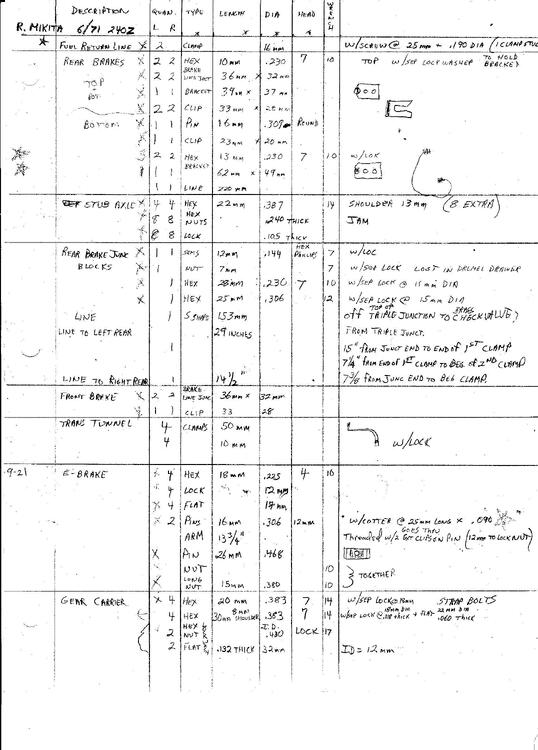

This car had some moisture, condensation from sitting in the weather all these years. Hot summers, cold winters, all kinds of weather. It was at this time I got one of my favorite tools, a harbor freight blast cabinet which I upgraded to a foot pedal etc. More tools included a spot weld cutter bit, a welded for welding thin metal. I have welders, but they're for heavy logging equipment, not this. As I took the car apart, I carefully bagged up the parts in separate labeled bags. About this time, I started reading Motorman's "the Orange" and "Deja vu" threads. It really inspired me to think "hey, I can do that!" But then realized to get parts plated, I needed to throw everything into a box together. Now my memory isn't that good, and getting worse every year, so, I decided to measure and record everything. It took days. The thickness and diameters I measured with a micrometer, lengths in millimeters. I wasn't to familiar with metric....so if these can help anyone, here they are. I had a couple shipments to Sav-On plating and parts of another car in these. As far as clear zinc or yellow, in some cases I may have gotten it wrong as these things were powdery/rusty color. I think this car was pretty much unmolested.

datsun invent 6 001.bmp

Subscriber

Subscriber 2Points100Posts

2Points100Posts