The replacement connecting rod for the carburetor showed up in the mail today from ZTherapy. Thanks @Patcon for suggesting I contact them.

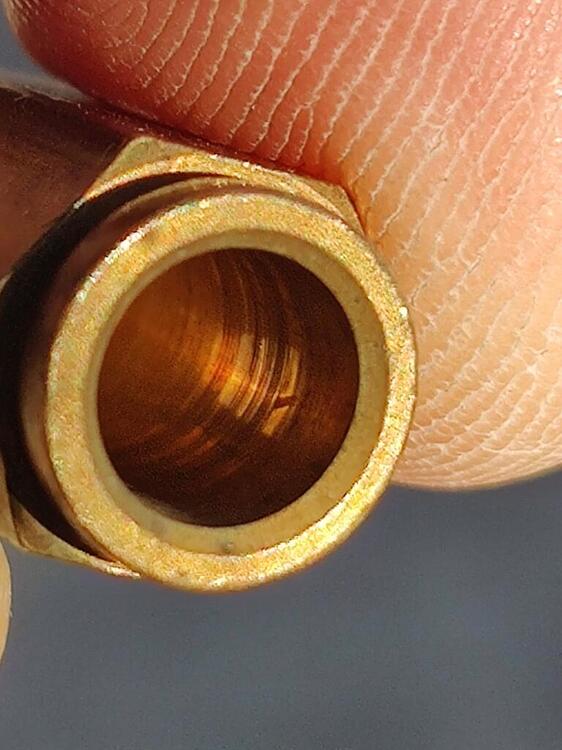

Unfortunately, the replacement needles and seats did not show up in the mail today. So, I found myself removing the rear carburetor needle and seat... just to have little look see at it for issues. Well, one thing led to another, and I found myself on Youtube watching a video someone made about their needle and seat not working properly and causing fuel to gush everywhere. That person used a Q tip in a drill and some metal polish to polish the inside barrel of the seat. I decided to have a close look at mine.

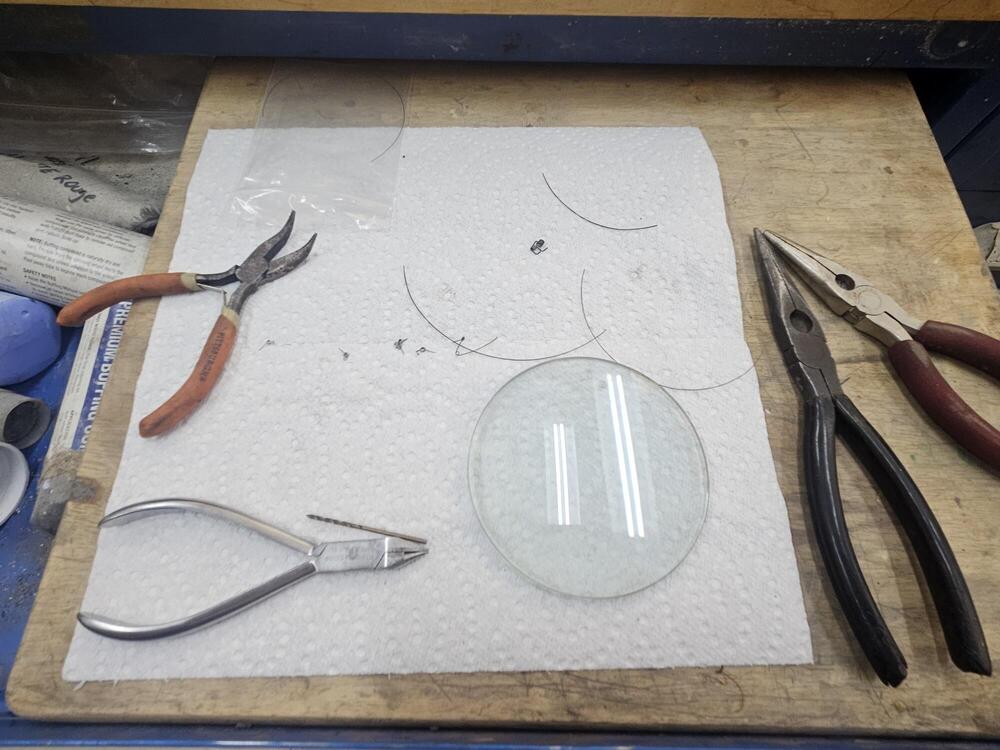

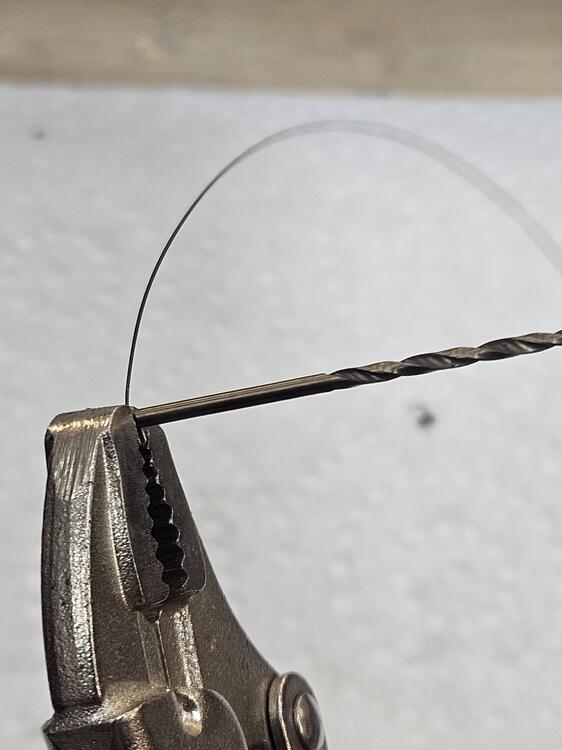

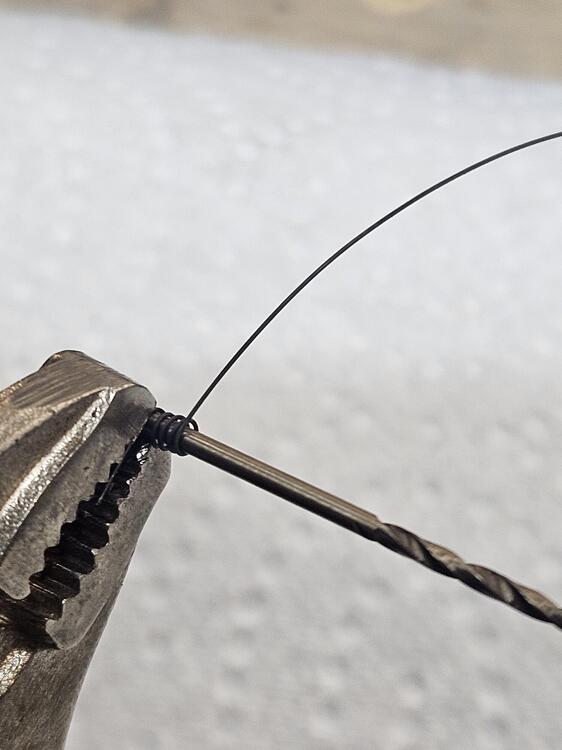

I wasn't able to take a good picture, but you can kind of see from the above one that the inside of the seat bore where the needle sits is not exactly smooth. So, I grabbed a small section of 1500 grit sandpaper and rolled it around a drill bit which I inserted into this bore. Using the drill, I smoothed out the ridges on the inside of the seat.

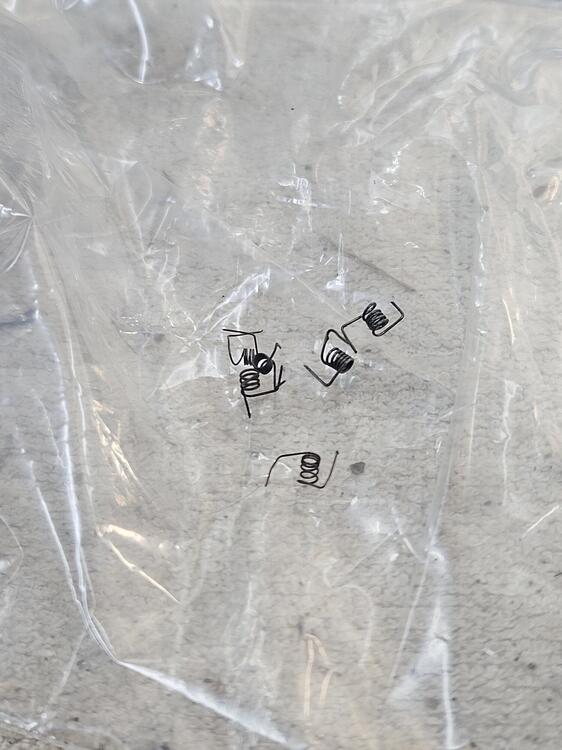

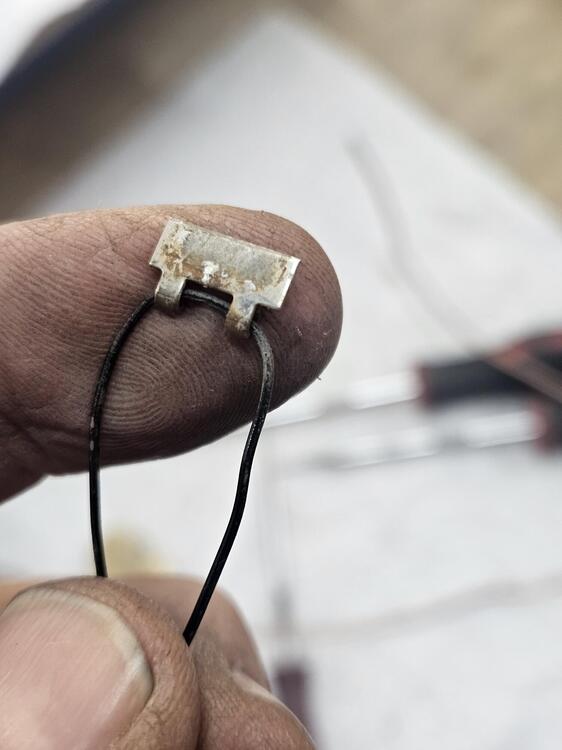

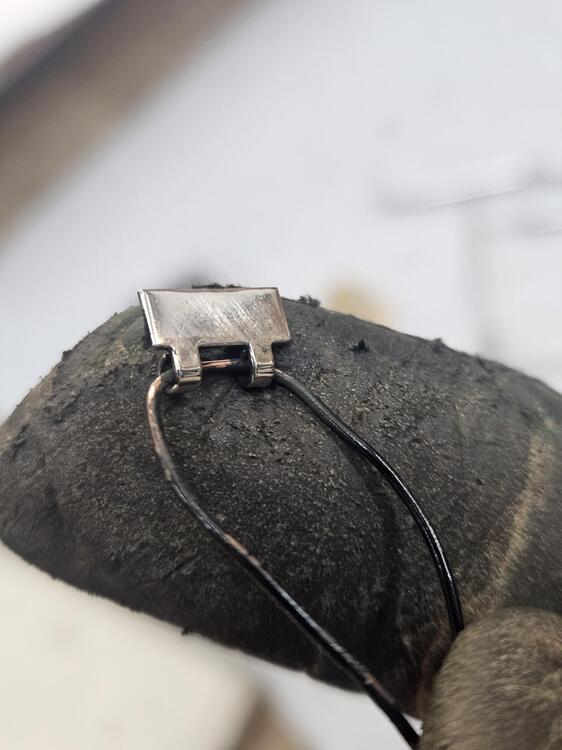

Then I used a Q tip and some metal polish and a drill to polish the inside of the barrel. I then sanded the corners of the needle with some 2500 grit sand paper and polished the corners of it as well with the Q tip and metal polish:

I

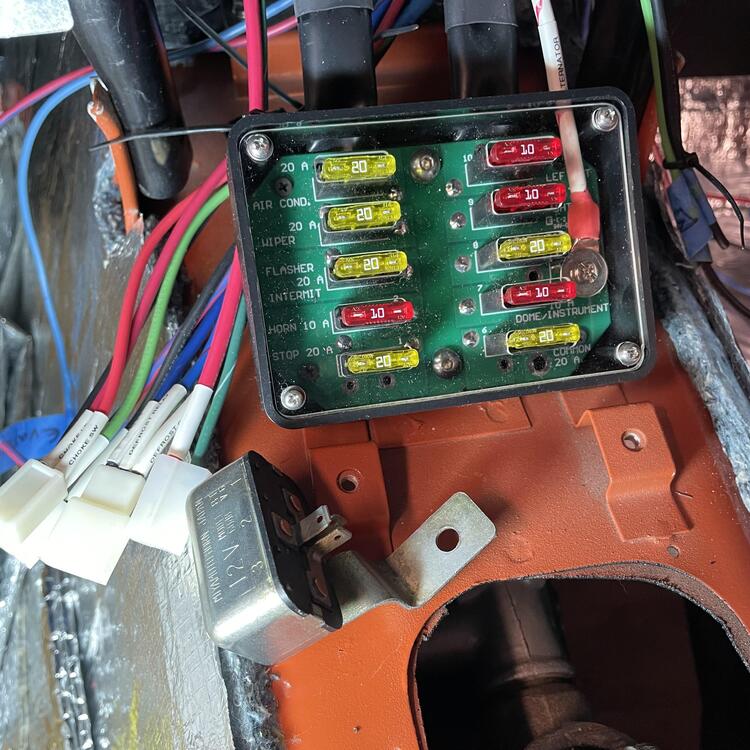

After cleaning them, I put the needle and seat back together in the carburetor. Because I had to take the linkage apart to install the new connector rod, I synchronized the carburetors again.

Here is something interesting: While I did the standard balancing procedure which included setting each carburetor's set screw so that each carburetor had the same flow at idle, and then screwing in the auxiliary shaft screw (to activate the linkage against both carburetors) and setting the balance screw to have the same flow during throttle application, I also did something similar for the choke. This is not something I saw in the factory workshop manual.

For proper choke function, the factory workshop manual provides instruction to set a specified gap between the throttle plate and the body of the carburetor when the choke lever is pulled. This is to be done for each carburetor. After this is done, in theory, when you pull the choke lever, the choke mechanism will open the throttle plates on the front and the rear carburetor the same amount. I did as instructed in the factory workshop manual.

However, I then started the car with the choke lever slightly activated. This raised the speed of the engine above normal idle speed. And then, I checked the flow of air through each carburetor using the Uni-Syn. Well, the flow was not the same. Similar to the procedure to balance the front and rear carbs when the linkage is activated, I used the Uni-syn flow meter to set the flow between the two carburetors to the same amount with the choke lever in operation (slightly). To adjust flow I had to shorten/lengthen the connecting rod for the choke.

After completing this adjustment, when I pull my choke cables to start the carburetors, both throttle plates are opened to a position where both carburetors are flowing the same!

I never was able to get the chokes working well on my track Z (when it had SU's), but I think this will be the ticket to getting the chokes to operate well on this car. I will be able to test that tomorrow when the engine is cold.

I did take the the car for brief drive after messing with the needle and seat. So far, so good! I hope I have solved the issue with the rear carburetor puking fuel.

Subscriber

Subscriber 9Points11,140Posts

9Points11,140Posts Subscriber

Subscriber 4Points1,281Posts

4Points1,281Posts