I wanted to add to this topic for reference. I recently tried to rebuild the OEM units without success. I learned the first time that I never wanted to do this job again, yet here I was. This is a factory AC car, so it is slightly different at the heater core than @mikev88 has setup. These are the parts I ordered:

4 seasons vacuum heater valve 74604 (1)

4seasons heater valve 74827 (1)

Heater Hose Connector 5/8"X 5/8" Hose Barb Glass Filled Nylon PA66-GF33 Straight Fittings (1)

Gates Hose 19402 (1)

hose clamps

vacuum hose barb , M-M (1)

Vacuum hose

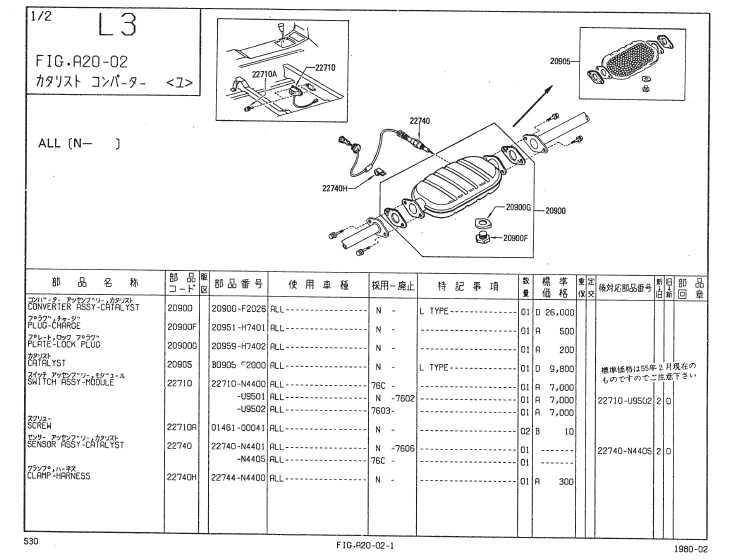

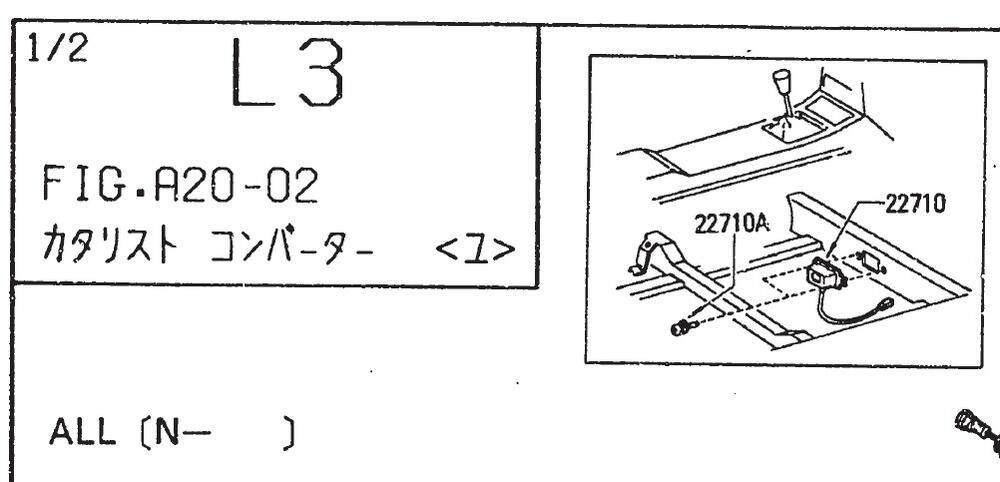

I wanted to make this simple unlike the stock installation. First off was the 74604, I mounted that in the engine bay. For the vacuum line - you will have to make a new hole in the firewall grommet and push the vacuum hose through there. Then connect up with the hose barb to the stock line location under the dash (W for my 1977).

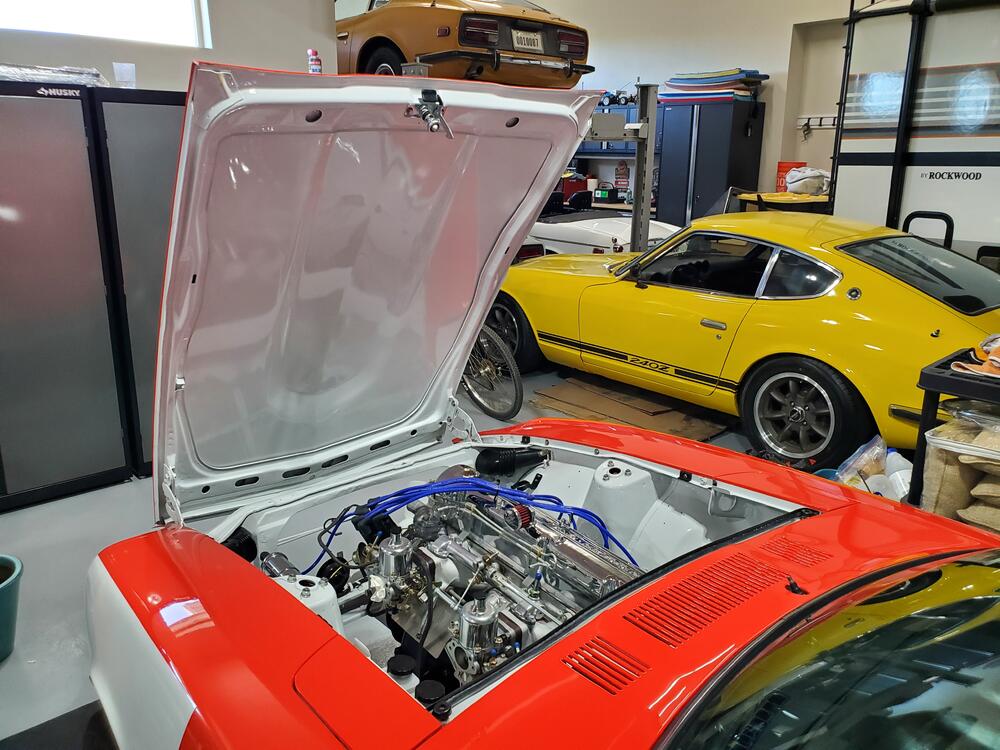

For the plumbing into the valve, I was able to use the OEM hose off the block that went to the firewall. just rotated about 90 degrees to mount up the 74604 to it:

Why this wasnt done at the factory, well thats a mystery! much cleaner and easier outside of the engine bay. For the factory grommet that seals the lines going through the firewall, you will have to enlarge 1 hole to fit the hose through it. I just cut where the lines were on it and it fit perfect:

From the 74604, the Gates hose (19402) has a lot of bends. You just need a long J bend to go from the heater valve through the grommet and through the firewall. The other side will connect to the 74827 (under the dash): This is my installation before I rotated clockwise another 20-30 degrees :

For the heater control wire, you will need to use some pliers and make a loop at the end of it. the new valve doesnt travel as far as the OEM one, so adjust where you want the lever to be on the dash. I lined everything up on full cold and tightened the wire holder down. Finish it off with a internal star washer to keep it from popping off. You will use the rest of the gates 19402 hose with the S bend to clear the outlet from the heater core to the new valve.

For the outlet from the heater core, I used a stock hose:

from the outlet, it went to that OEM hose, then to the 5.8" barb, through the firewall and through the grommet on the uncut side. Make sure to get the grommet pulled through to the middle of the barb. From there, connect to the stock hose.

Everything fits and there is more room under the dash to work with. Reuse some of the OEM screws that came off the stock mounts to keep the side plastic onto the heater box. No issues with the setup and if there are future issues, it will be much easier to deal with. Hope this helps someone out there

Subscriber

Subscriber 4Points271Posts

4Points271Posts