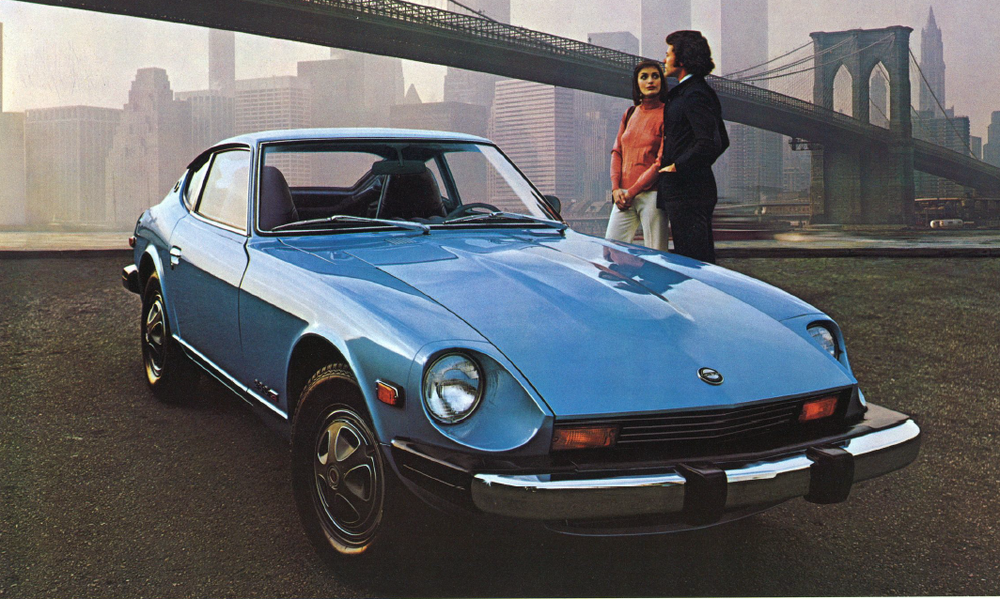

Not a 78 owner but I know a little about this. 77 and 78 280Z's had side mount blades instead of the top mount used on 70 thru 76, all had the twin wire blade design. Also in 1977 it was mandated in the US that wiper arms and blades be black. Here are a couple of images from 1976 and 1977 280Z sales brochures.

1976 280Z with early style, unpainted SS twin wire blades and top mount arms,

1977 280Z with later style, black painted SS twin wire blades and side mount arms,

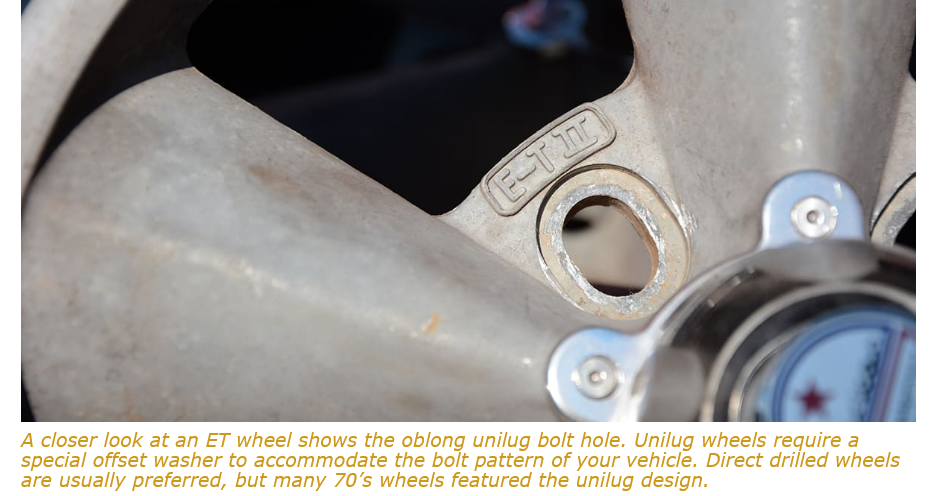

When I was on the search a few years back for replacements (I had aftermarket plastic blades) I got a set of the later style blades and arms that I decided to use on my 1970, When I got them they has quite a bit of the original black paint that I had to remove. Turned out pretty good, most people wouldn't know that they are not correct for my car. Here's a couple of pics of mine for a better look at the difference of the 77/78 style.