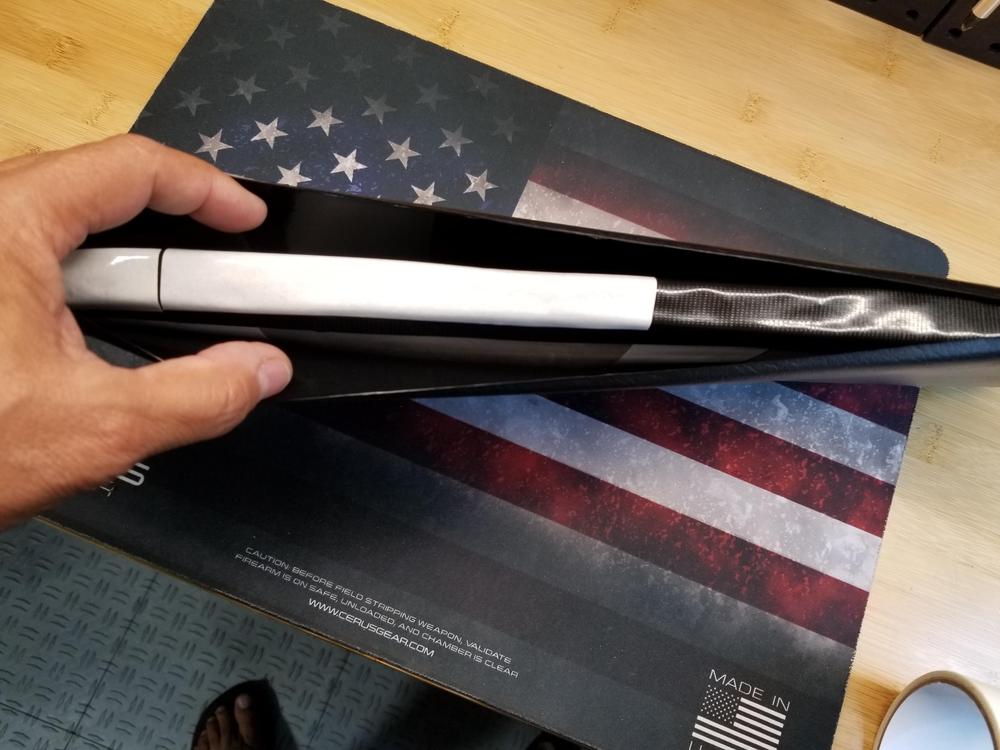

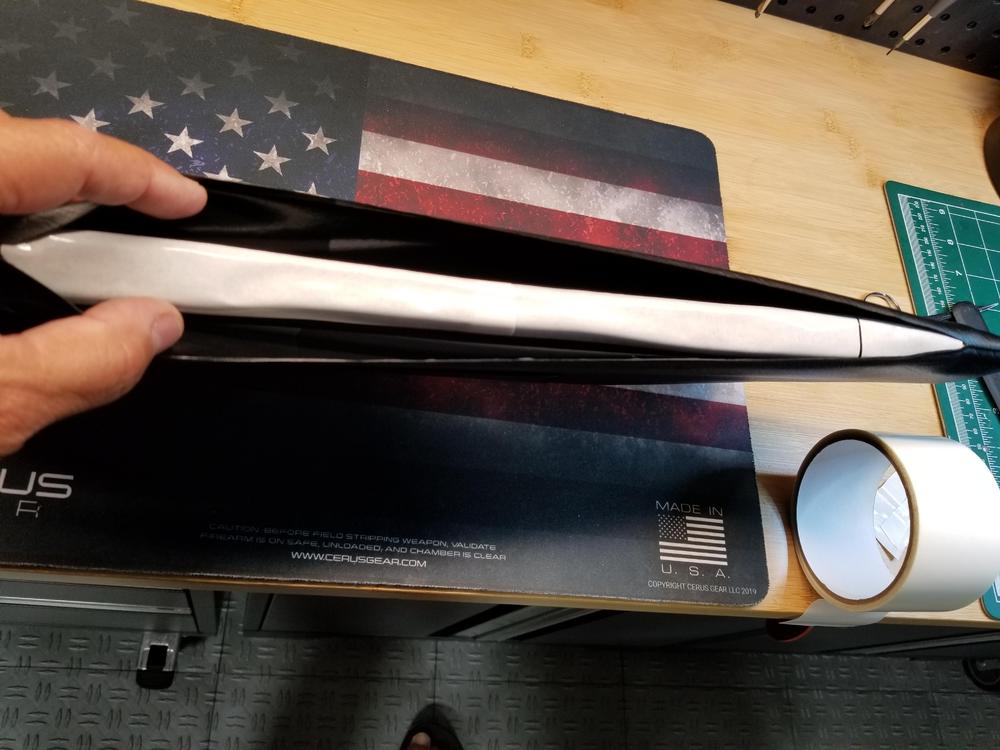

Today I turned my attention to the alternator, to see what I could learn about it, and share some of my early findings. Works cars had up-rated alternators with on-board voltage regulators, which was a departure from the S30 production cars. I've attached a few close-up photos to show how it looks in the car, and from the bench. I've also included a photo of the alternator used in the 1971 Monte Carlo - to my eye, they look similar enough to be considered equivalent, although I don't see any part numbers on the alternator, so there is no real way to be 100% certain.

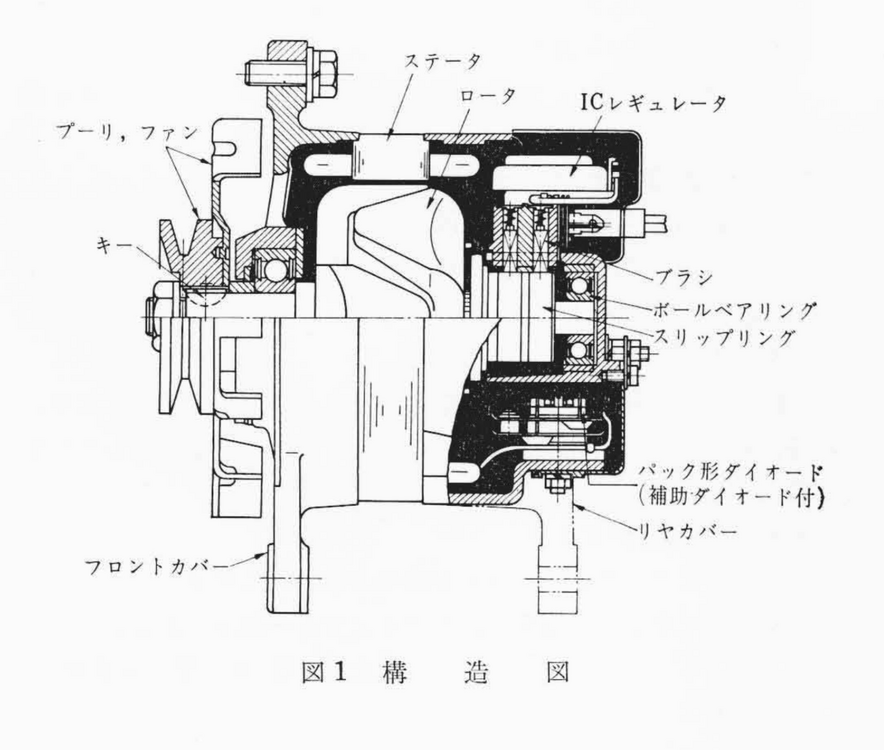

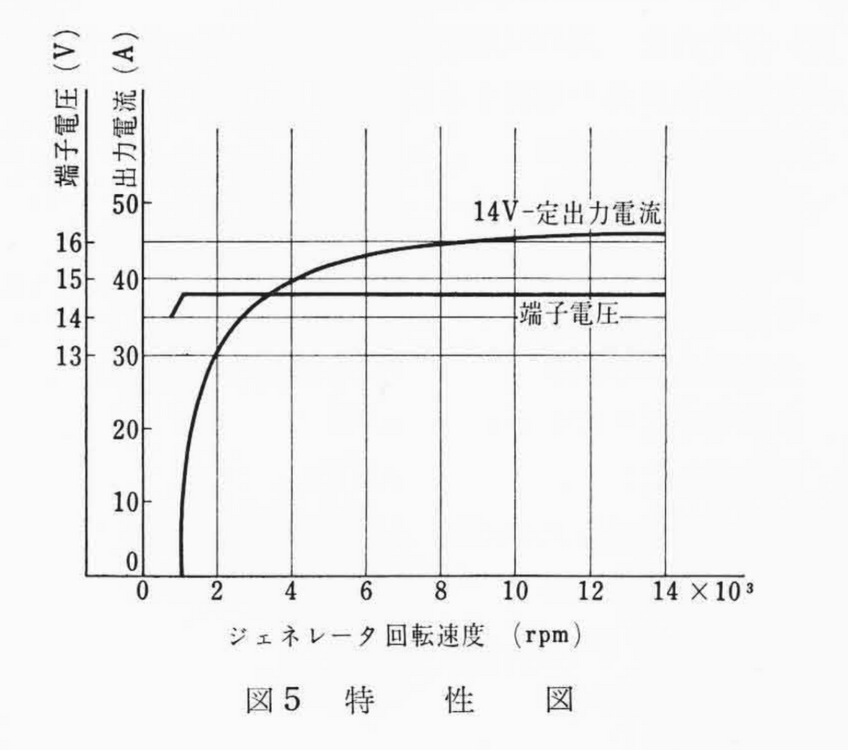

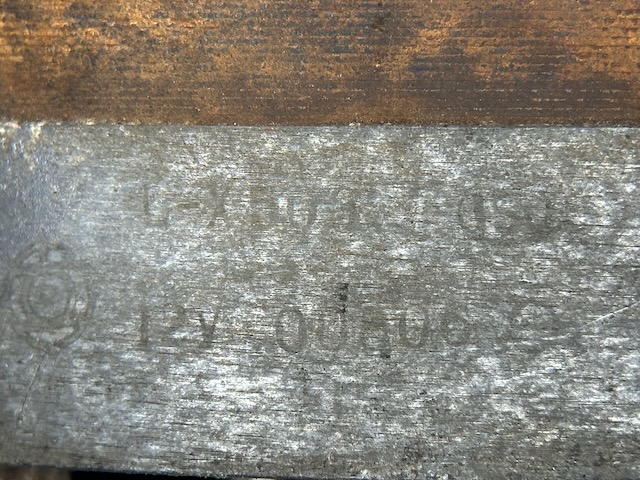

Without having any markings on it that I could see, I elected to disassemble it in anticipation of getting it rebuilt and ready for use. I didn't get very far before I had to quit for the day, but at least I was able to disassemble enough of it to get a picture of the markings on the voltage regulator - it's a Hitachi TR1Z-06. Based on a 1971 document I've downloaded from Hitachi's site, a version of this IC-based alternator was used in the Nissan President and Cedric, and it came in 40, 50, and 60A models. I'll need to bench test this one to determine its actual output.

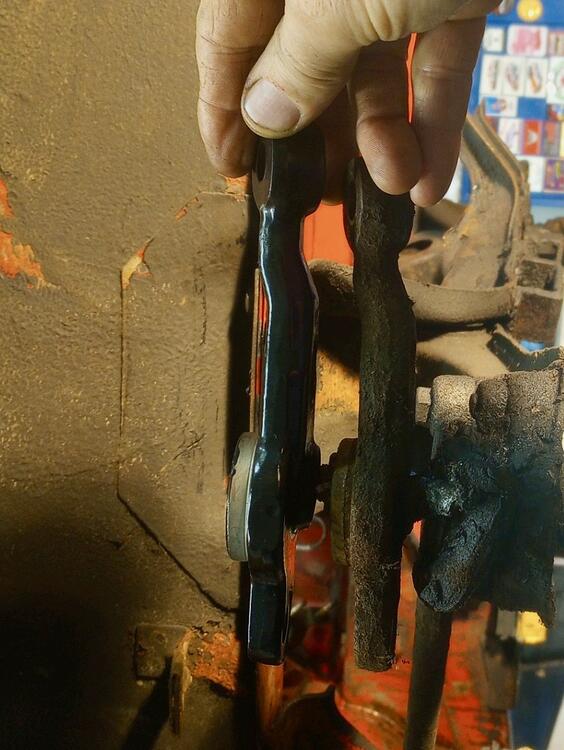

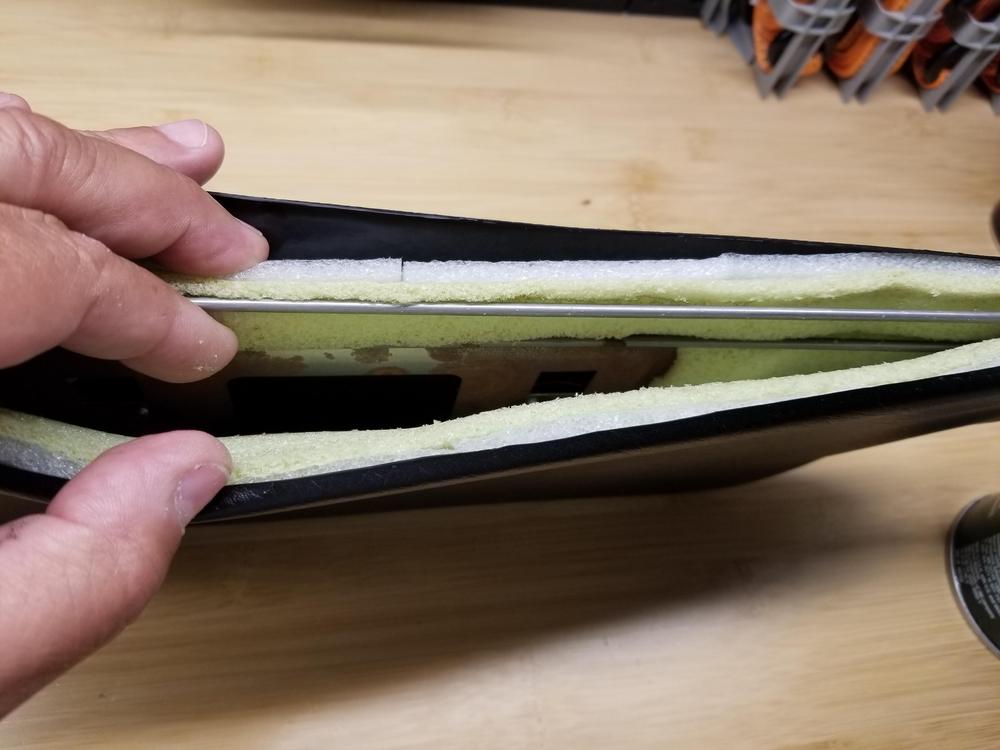

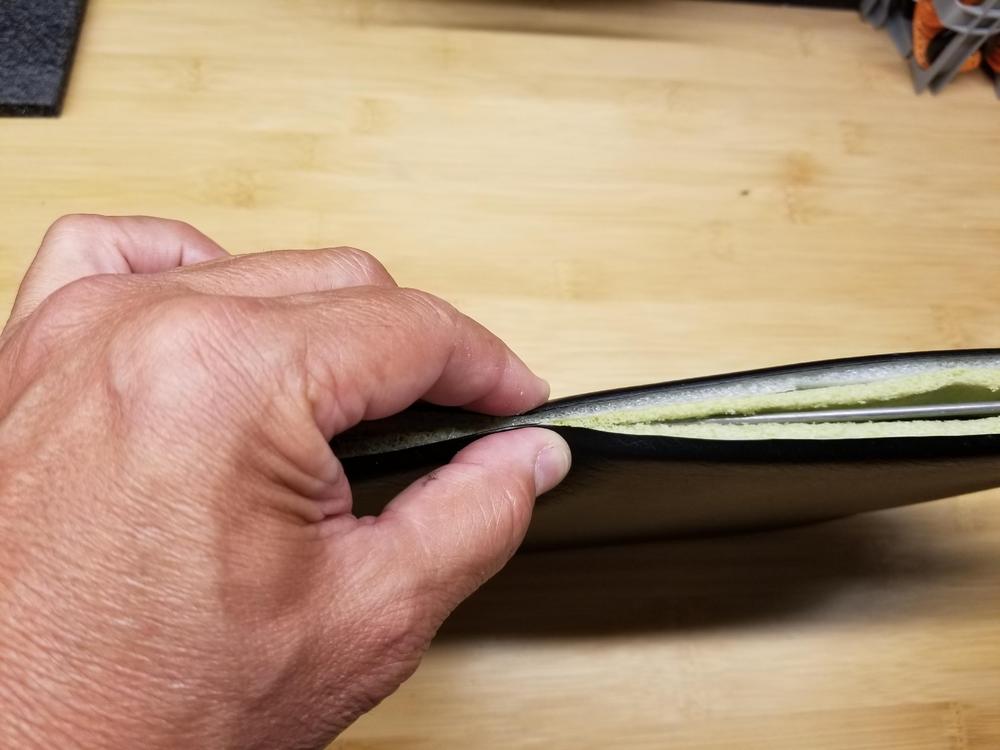

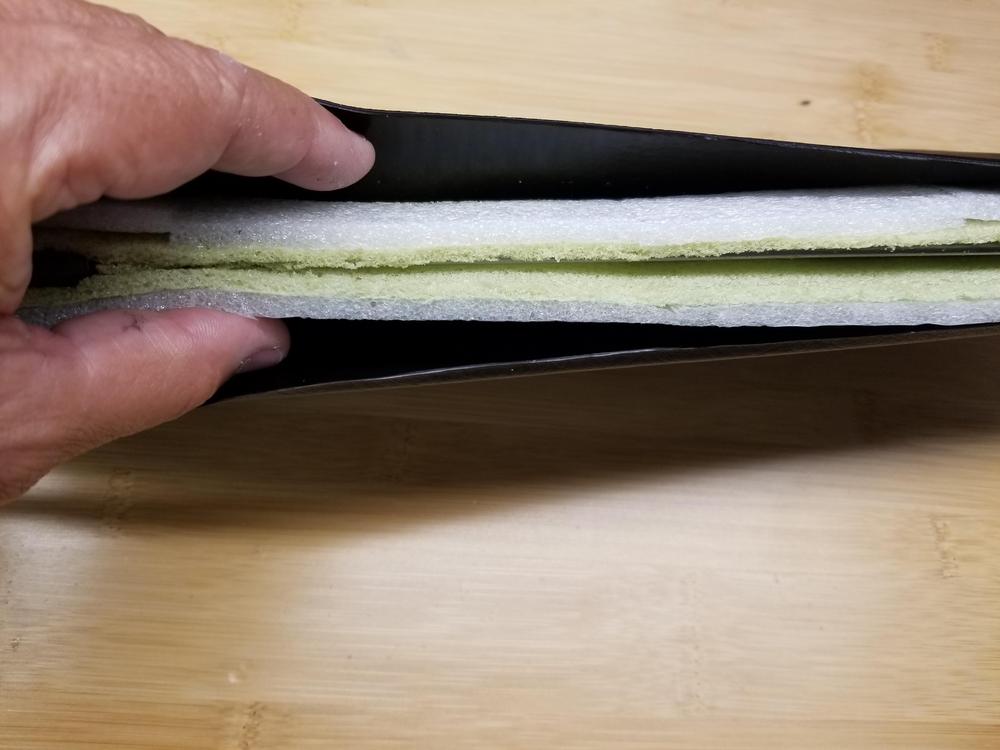

It appears that stock units did not have the protective black rear cover (see picture of a stock example). It was likely added by the Works team to provide additional protection to the voltage regulator.

.thumb.jpeg.c9499c5e52601d778622258a0854128e.jpeg)