2. Speedo Upgrades

The issue here is the ever changing differential gears and tire selections we just can’t help making. The limited choices of transmission pinions gear tooth counts means you might get close, but you will never be very close…..

Well, there is a cure. Actually many cures

GPS Speedometers. These have been around for a while

a. Cheap dash mounted little box that displays speed. Amazon is loaded with options.

b. Your cell phone. There are 150 free speedo apps out there. Did I say free? Hardly easy to use in continuous and easy fashion though

c. Dedicated aftermarket gauge manufactures. Speedhut, Dakota Digital and others. Seen and owned the Speedhut GPS speedo for my Z, it was great. There are now shops making 3D printed mounting rings for Z’s for all 5 holes. Fabulous.

D. Here is where it gets interesting. In my 69 510 (same issue for 68), I do NOT have a round speedometer. It is an old school rectangular sweep speedo. See pic below (not my car, 68 actually but ~same as 69). I love it, I want to keep it, but there are no aftermarket options for this style of electronic speedo.

So I start searching for solutions.

Step one was DIY stepper motors. Pun intended. Cool stuff. You tell a motor EXACTLY how fast to move, or even better, where to EXACTLY STOP at whatever rotation position you like. How do you think all the OEM’s have been building their instrument clusters for 1000 years? How do you think Speedhut and others build THEIR gauges today?

But you say “how can a simple backyard mechanic figure out how to get this electronic gizmo’s to work?”

Well it turns out that while we have been toiling in the garage and watching Bachelor in the evenings, the engineering world has been invented a huge range of DIY electronic packages designed at the “young” to get them into robotics and STEM learning. Search ARDUINO or RASPBERRY PIE on youtube. You will spend countless hours saying “OMG” to yourself……

Let me sum this up. After spending $50 bucks in boards and bits, and investing 15 minutes watching a YouTube video, I had a working tiny stepper motor (actually a 2$/100 generic GM instrument stepper motor) driven by a square wave frequency input (more on that in a minute) moving a toothpick speedo needle to anywhere I decreed. FM!

Now I have to admit to being a actual engineer (EE) and this stuff ain’t completely new to me so it was “easy” for me to make this leap, but I just didn’t understand the breadth and scope of what is truly EASILY possible now.

This leads to the following revelations. Got a fuel gauge that doesn’t match your new fuel sender in your new tank? No problem. Don’t want to spend the current insane $500 USD and up to find a used and rare stock tach for your 510? Make you’re own……

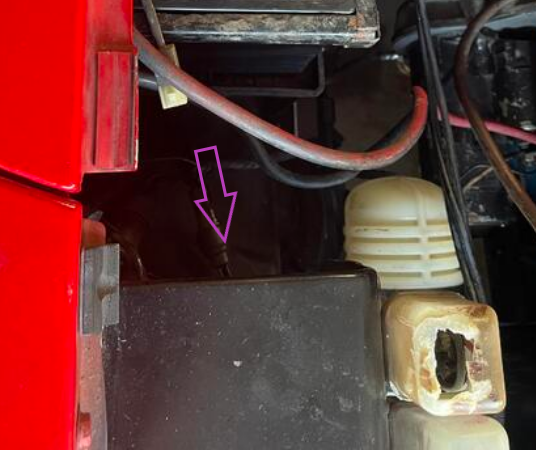

Now I’ll show the next link in this chain, The VSS. Vehicle speed sensor. To drive all this fancy stuff, you need to have a digital signal that tells you have fast your driveshaft is spinning (needed for cruise control too!)

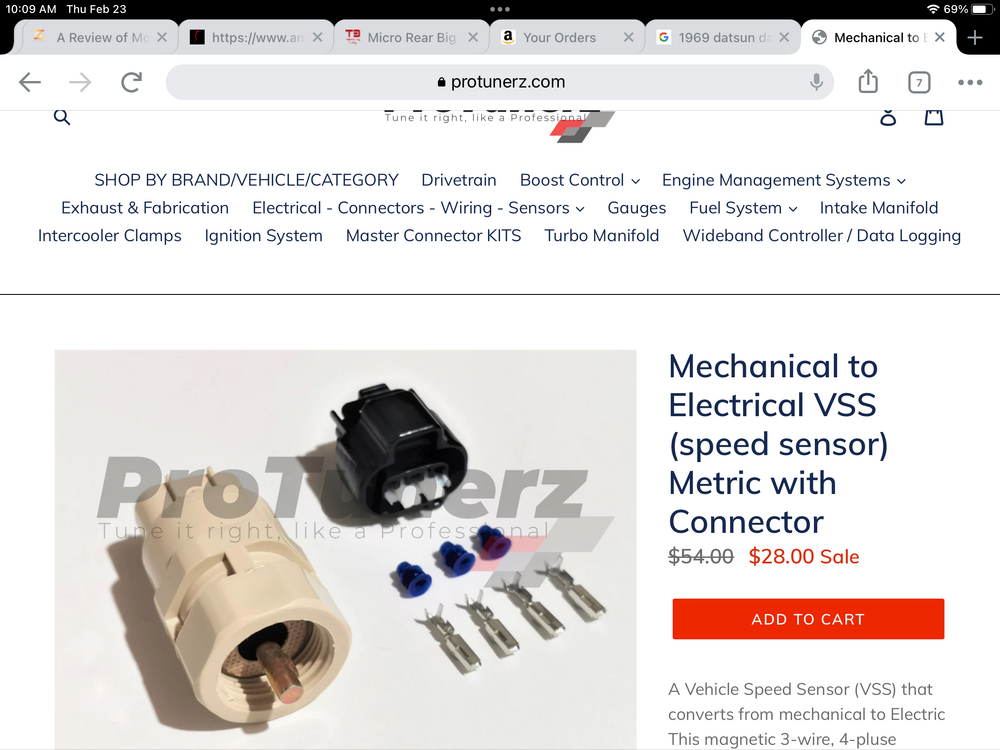

Well there is this cool little device, available from ProTunerZ. I first tound it years ago through a Toyota 4x4 supplier.

https://www.marlincrawler.com/transfer-case/parts-upgrade/misc-hardware/vehicle-speed-sensor-mci

Turns out the threads on the toyota tranny’s speedo cable pinion is the same as Datsun.

Screw this little gem on YOUR speedo pinion add 12v and a 1K resistor, and you get this lovely perfect 12v 50% duty cycle square wave output at a frequency 4 times the pinion rotation rate. For $28 buck.s Yeah.

BTW, the gear ratio of YOUR speedo pinion is computed by dividing 6 by the # of teeth on whatever pinion you have. 6/16 (yellow 16 tooth I think) is .375. So at 3000 RPM driveshaft speed your pinion is going 0.375 times slower. Use your tire circumference and diff gear ratio to compute Rotations per mile.

Subscriber

Subscriber 3Points428Posts

3Points428Posts