Sorry for the later reply, busy season with work.

I intended to restore an RS30Q, and had the car, but the CSP took its place, and the RS30Q was sold, so I never got to try I found/modfiy/stock set up.

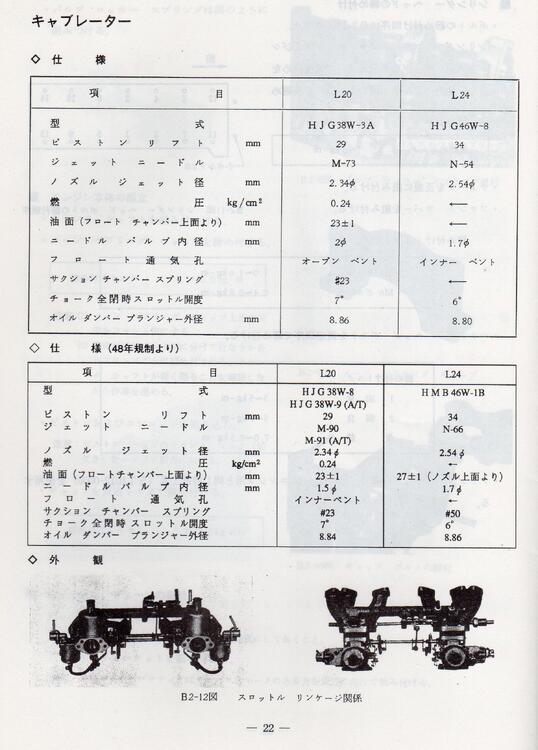

It's been a while since I was in Flat top carb world. A quick look/thought.

On my parts microfiche, there is only two needles listed, 16354-N3500, N-86A and 16354-N3310 and listed as applied model is L26 Australia.

Mentioned above is HMB46W -1 to -10, looking in the 240z/260z fuel system modifications plus booklet, mentions on page 18 "note: HMB46W-5 and -9 carburetors have the improved choke valves (no stamped number)." On the previous page (17) is mentions F1 and R1 as the second type, the third type F2 and R2, where Fand R are front and rear carbs. This corresponds to choke part numbers, 1st type, no part number (and that page is missing from my microfiche), second type 16188-N3300 and third is 16188-N3310.

The power valves also correspond to F/R1 and F/R2, (16059-N3314 and 16059-N3313 respectively, with the later having a green blob of paint on the valve, which I have seen.

So, what I am trying to say, point to, is I think the -1 to-10 covers small modifications/tweeks, with the HMB46W's as there production progressed. It also on what model the carb was on. I am unsure if any JDM market had the HMB46W fitted (HS30-H?), apart from their recalled Fairlady Z with the 2.6L fitted. It could like the Hitachi HJG38-11, NOS I have, this having an -11 suffix. This carb was I think, ran as singles or twins on various models, the P510, Fairlady Z, B110, N10 Cherry, all these models. I very much doubt ran exactly the same carb, cc would mean that needle valve would differ. The fuel inlet pipe on the NOS one I have differs in orientation than others I have seen, does this warrant a -* number change? The HJ38 has its number etched on the side of the fuel bowl.

Which brings me back to needles...I haven't seen anything with 1A to 1C (probably as the 1st page of my copied microfiche is missing), but I think it is lining up with changes to other modifications/tweeks to the carbs. I did send a needle off to be matched with an SU Burlen one, and it was pretty close.

I completely stripped a pair of HMB46's years ago to try to get a better understanding of these "boat anchors" work. People can run these carbs successfully, and some can. It's only fuel air and vaccum...! The key I think is they have to set up just so, and are a little less forgiving than the HJG46W. Some of these set up points are in the fuel modification system. What I found on stripping them if I recall is the nozzle kit (16496-N3311) is very easily worn, where the needle cuts a groove/makes the nozzle oval, rather than a centred fit. I found the power valve assembles clogged up with carbon, the valves are made up of 3 or 4 plates, with the centre one has little set brass nozzles set into the aluminium housing. These power valves run off a separate curcuit if I recall, giving an extra shot of fuel at a certain level of throttle, so have to be clean. I think there is a knock on affect if things are just set up just so.

The throttle shafts like the HJG46 could do with bearings inserted like Z therapy do. Also, if I remember rightly, the HMB46W's there is only one idle mixture screw that does both carbs, linked to both via hoses. This makes tuning difficult, as there has to a happy medium (or unhappy) to get it to run as best it can. I did come up with a mod that gives you individual adjustment to each carb, which I think would help.

Fuel level, very crucial, they eye level glass is a faff to see. The volume of the fuel bowl, which is under the carb is quite small, so getting that fuel float set is crucial,which is linked to fuel pressure. I did think of a large fuel bowl (cut a slice off a spare carb and make it into a spacer) to give you more volume, but I never thought it all the way though and see if it would work.

I seem to remember a very small inset fuel filter in the carb body, another thing to keep clean. Also, there are devices on the air filter box that need to be kept in working order too.

Right cup of tea time. I hope that helps.

Cheers

Ian

Subscriber

Subscriber 2Points1,333Posts

2Points1,333Posts