The recent 75 that I just parted out displayed quite conflicting “usability” or should I say “re-usability” in many components that come in twos. The car had sat outside for I’d estimate 10-15 years at least. 95000 mi on the clock. 195000? Maybe....

1. Spindle pins. Right side came out easily with my usual simple air hammer technique. Left side, no such luck. Even after upgrading my air hammer to the best one available (ingersol-rand 123KMax) and heating with dual MAP gas torches to 600C +, not even a micro-millimeter of movement. Off to the machine shop we go. I even cleaned out the cross pin area, although it came out without a fuss. Haven’t had to seek outside help for quite a while.

2. TC rods. Right side is near new, left side again not so much. Significant corrosion under the sleeve at the bushing end. Just enough to make me not want to re-use it.

3. Drum brakes. Unlike the usual drum to hub corrosion, this left side came loose with only a few hundred mild blows from a 5 lb, but then had to literally pry the drum off, the totally worn out brake shoes where bonded to the totally worn down steel liners and actually peeled off parts of the liner when it finally gave up. Right side? Just came apart.....

4. I previously shared my struggle with the lug nuts on the left rear side. One that had to come off with a ridiculously long snipe and a left hand thread lug remover socket

So its no mystery to me that the car sat more on its left side in a damp spot.

There were also many pleasant surprises.

The gas tank interior was sparkling clean, as well the fuel level sender. The filler hose is still soft enough to re-use easily. The tank itself has some dents, which I will chronicle the removal of here later. Going to try one of the hot glue slide hammer dent puller thingamadooees.

The hinges are like new, pin play and roller detent wise. How is this possible?

The e-brake cables are free to move in the sheaths, which are in great shape! Again, Huh???? The rest of the linkage is dirty and seized some, but un-seized with little fuss. Even the lousy M6 threads on the adjusters just cleaned up with a wire brush and PB Blaster and the nuts move just fine. The little rotten cotter pins all came out with a fuss, as did the the square C clips that hold the brake sheaths to the brackets under the car.

The tar mat sound deadening came off in huge sheets with my fingers. ok, the floor under them was mostly gone, that ones not fair.

The steering wheel, the infamous sponge rubber “rotten on top where the sun shine, not bad the rest of the way around” was EVENLY rotten all the way around. Spooky. Actually feels nice high grip in use.

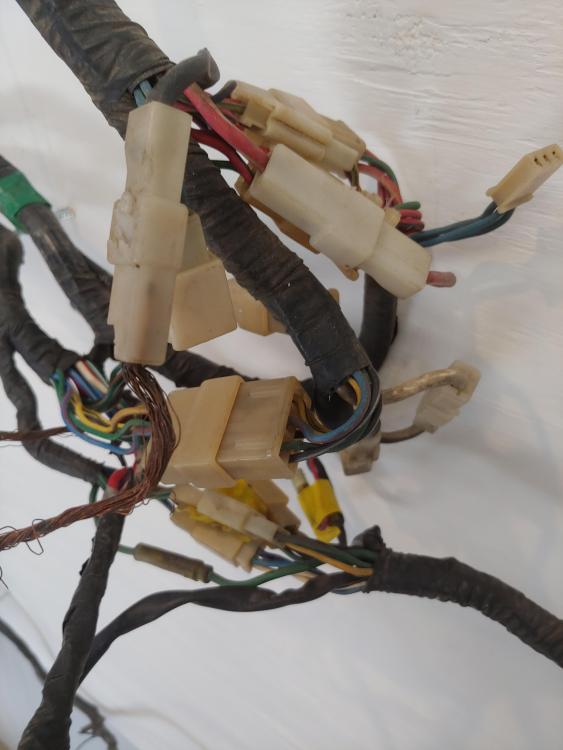

The wiring is totally un-molested and in pretty good shape.

No the clock was not working. I was sure it would work given the other nice surprises.

Wiper linkage and motor. Primo! Even the 6 little M5 bolts that hold the linkage to the cowl came off without much fuss.

Sun roof. too bad.....

Front clip from in front of the shock towers forward, near perfect. Remember the hood prop clip still in place and unbroken? Still is. Saved it.

Battery tray and surrounding body is nearly rust free!!!!!!! Saved it

Now the rest of the body from the rockers down, actually bottom of doors down, was GONE. It was neat to see the seat rails still attached to the sills and trans tunnel, but half gone on their bottom where the floor was.....

Subscriber

Subscriber 3Points3,770Posts

3Points3,770Posts