going to share my rack re-build here for anyone that is interested

first I disassembled the rack, ( well documented in the FSM and here ) , then I assessed the condition of all the major pieces

1) the inner tire rods were good and tight with no real play

2) the rack end bushings were mixed , the drivers side showed significant play, but the passenger side was tight.

3) the pinion bearings were shot, in fact the housing was partially full of water

so then I tried to source parts, the standards stuff was available, I ordered rack mount bushings ( rubber ) , bellows, and outer tie rods. however the internal parts, end bushings and bearings were not available. so I had figure out something

I ordered bearings from mcmaster carr, that I think will work with a spacer.. the originals are angular contact ball bearings, 15mm id x 35 mm od x 12 mm thck. looking thru the mcmaster catalog I found https://www.mcmaster.com/#6680k13/=16kgt7i which are very similar, just need to make a 1mm spacer to make them wide enough.

I measured the rack itself and it is 25mm, so I looked for the bronze bushings that might fit, could not measure the OD of originals before I got them out but they were around 1.125" . the closest thing I found was http://asbbearingsonline.com/index.php?main_page=index&cPath=103_105_109 so I ordered 2 z90-2530

Last night I replaced the drivers side rack end bushing.

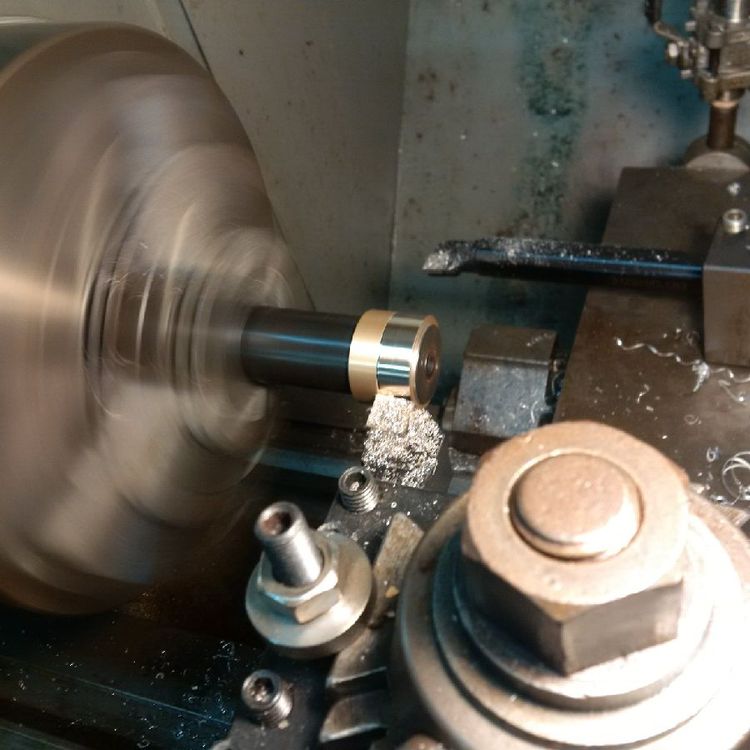

could not get the sleeve bushing to come out with my harbor freight id puller, so I ended up cutting it lengthwise with a hacksaw blade ( almost all the way thru ) and then it pulled easy. I measured the remaining bore in the rack as 1.124" ID. the bushing OD measured 1.185" or so, so to the lathe !

the hard part of most projects like this is how do you hold the part ? luckily I had bought some expanding collets. so I started by machining it to the .984" diameter of the bushing

then I put the bushing on it, expanded the mandrel , and turned the bushing OD to 1.125 giving me .001 of press fit.

After pressing in to the rack housing, ( using the collet and a hammer.. plus a little torch heat on the housing ) the ID of the bushing had shrunk a bit, so I had to hone it with a brake hone.

So after a 30 mins of honing and test fitting, I got the rack to slide smoothly in the housing with no detectable free play

NIce! next I will work o the pinion bearings and see if I can make them work.

Subscriber

Subscriber 2Points3Posts

2Points3Posts