Some news! I started with some more body work and welded the first time on the body!

At first I was really intimidated as a welding beginner to weld on thin sheet metal, hearing all those stories about warpage and burning through! Of course they do happen if you’re not careful, but after some practice on scrap metal I got the hang of it! I’m by no means a professional welder, but pretty much all of my welds will be grounded down, so they only have to be strong, not look good! Even though every now an then some pretty once even came along!:)

First task was the rusty metal under the hatch sheet metal. Sadly I did not take pictures in between, but this was what i begun with:

And what I ended up with, already grounded down!

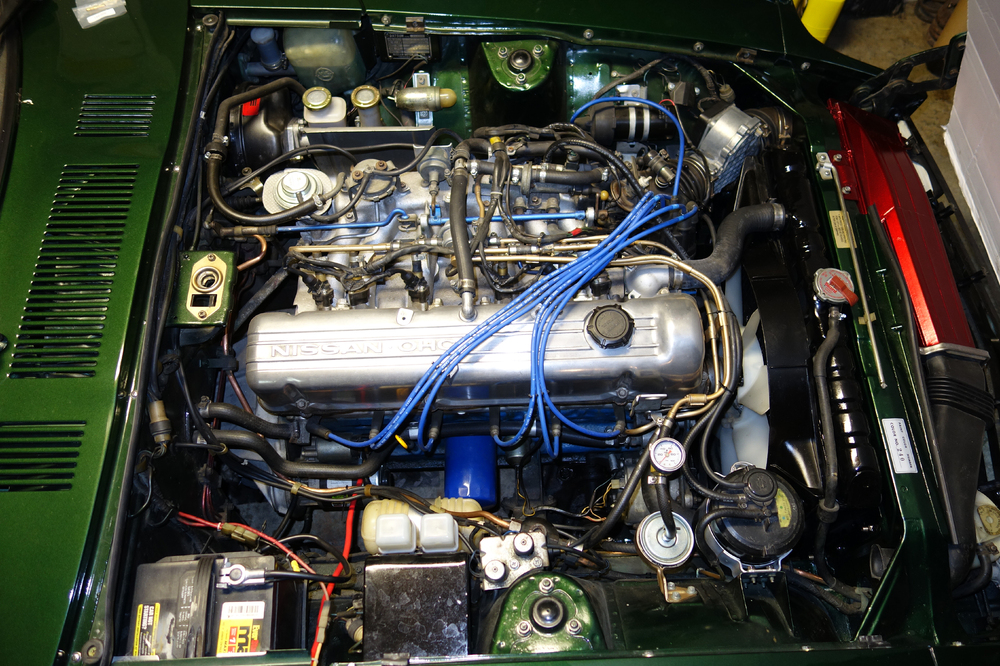

The next task was the battery tray! Even though mine was in quite good shape, minus one rust spot, it had to go anyway since I’m relocating the battery under the passenger seat in my quest to clean up the engine bay and make it oh so pretty!:) Still “in”:

And out it goes!

So if anyone’s interested, the battery tray’s for sale as is (Europe!)! Maybe I’ll restore it later down the line, really come to like welding, and make some more profit out of it.

To still be able to work inside the garage, where it was at most one or two degrees above freezing, I planned to weld in this new piece. But since my zinc spray decided to not work, albeit being completely full and unused had to postponed it. Definitely want something between metals when I put two on top of each other. Either zinc spray, or this red weld through primer. Haven’t had much luck finding some in Germany though yet.

Today I beared the cold outside for some hours, shove the body out of the garage and further CSD-stripped the left rear where some body damage was fixed before with filler, and also some unrepaired damages. Got rid of almost all of the fillered areas, so I can see the damaged area, and try my best with hammer and dolly soon!

I also stripped all the areas where I needed to weld, being the chrome trim holes, as well as around the side marker holes to delete them!

And plug welded them shut! Actually pretty easy with a short rotating motion.

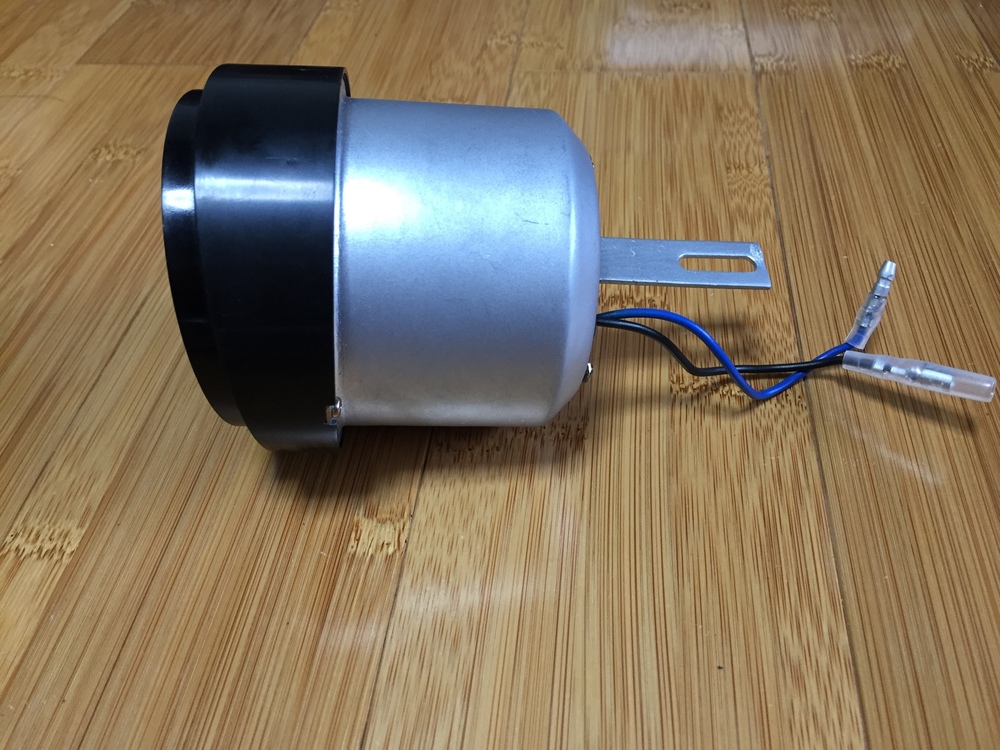

To delete the side marker holes I purchased the delete plates from Skillard over Zcardepot, after a friend recommended them. To be utterly honest I’m not impressed by them at all! The gap around is huge(!) for being a CNC cut item and one corner even had quite the indent. The picture beyond doesn’t even do it justice, it looks even worse in reality:/. A lot of bridging the gap will be involved. I hope they already fixed it! And am curious how the delete plates will perform on the front fenders!

Anyways, “butt welded” the plate in, again, not pretty but sufficient strong! Have to grind it down to properly weld the last gaps shut, as I wasn’t able to get in between the buildup properly. But that’s a task for the future, I got dark and more importantly utterly cold to keep on working!

Once again, let’s see how fast I get the bodywork done!:)

One last question though: I will be keeping the original frame rails, since they are in well enough shape still (minus some wrong jack up action, but not structurally critical), but I would like to extend them, maybe even connect them all the way back! What’s the best way without purchasing prefabbed frame rails, and not having a metal brake?

Have a happy holiday all you guys!:)

Subscriber

Subscriber 4Points3,770Posts

4Points3,770Posts Subscriber

Subscriber 2Points3Posts

2Points3Posts