All Activity

- Past hour

-

Z Restoration Progam

The point was that cadmium is still being used to plate parts for old cars. Zeddsaver is just an example.

-

Z Restoration Progam

I am only talking about the element cadmium, 48 on the periodic chart, and its use in plating metal parts for corrosion protection. Carl Beck suggested that early 240Z parts were plated with cadmium, HS30-H disagrees. Carl Beck says that he had some parts analyzed scientifically, at Honeywell. It's been a long discussion, not one that can be absorbed fully without reading most of the last three to four pages of posts. https://www.anoplate.com/news-and-events/what-is-cadmium-plating/ https://periodic-table.rsc.org/element/48/cadmium

- Today

-

Z Restoration Progam

Please, please be most careful when suggesting ANYTHING from zeddsaver. I, and a number of folks I spoke with over the years , had problems, some big/significant.

-

-

weatherstrip

It's been a dozen or so years since new, but whatever glue I used on the rear hatch weatherstrip of my 240 is failing. Looks like I didn't miss any areas, but the rubber is just coming a adrift. The original stuff on my '78 Mercedes and day-to-day 2006 GMC are still looking good. Any recommendations as to which adhesives to use, and which to avoid? Thanks, as always

-

New Nissan Canada commercial

Thanks for sharing! I don't watch much TV, so when Diane told me there was a Nissan ad with what looked like a yellow version of my 240, I had to check. Cool ad, although there will be those among us who find the rubber-burning, wheel-spinning parts to be "deeply offensive," to which I say, "suck it up baby sisters."

-

Z Restoration Progam

Quite the discussion. You all seem to be describing an element metal by its color. Cadmium is silver. It's the chromate additive that makes the color and you can't tell the difference between the cadmium chromate and the zinc chromate. There are ASTM and SAE specifications for plating in these materials. Yes, you can have cadmium chromate plating but how does this all matter? So, I wrote a brief forward and printed five copies of the original 2005 script. They are about 35-40 single sided pages, color pictures, spiral bound with a cover page. It cost me about $15 each to make this nice. I really need to keep one, two are spoken for right now so I have two and I can always print more. Let me know.

-

Z Restoration Progam

Did Nissan ever use cadmium plating? Was it in use and they switched or did they start with zinc?

-

Z Restoration Progam

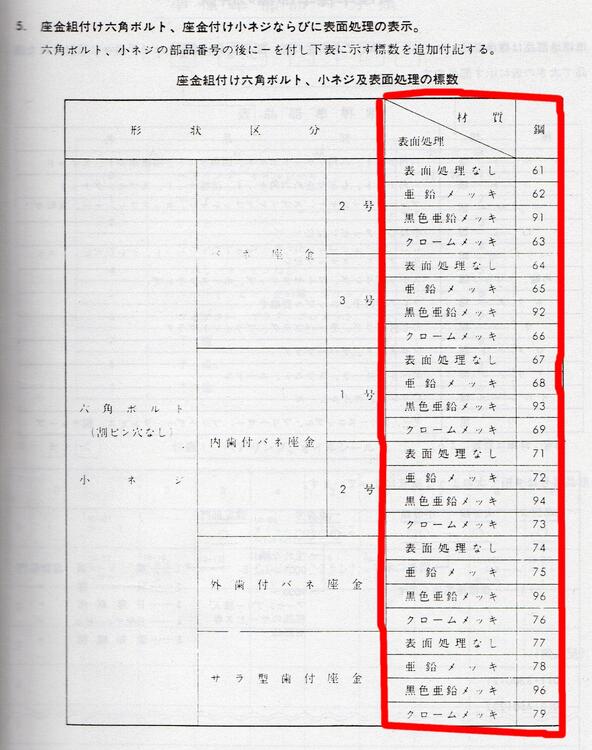

Vague? The Nissan literature - I've put it in front of you many times on this thread - reads ' 亜鉛メッキ ' (Aen Mekki). That translates fairly literally as 'Zinc plating', but many people will take that a step further and translate it as 'Galvanizing' (English spelling 'Galvanising', with an s). Black Zinc is also on the list. So we have an old-Japanese Kanji word for an element ( 亜鉛 ) sitting next to a modern Japanese version of an English technical process term ( メッキ ) written out in phonetic Japanese, Katakana. There's nuance involved which may well sail over heads who are not used to Japanese-English-Japanese translation, but the bottom line is that we are talking about a protective coating of Zinc, applied via electroplating ('Mekki'). You might be interested to hear that the original usage of the term 'Mekki' in Japan was in connection with Gilding. Yes, it's not strictly the true Galvanizing process (more suited to water tanks and shed roofs) but there's the nuance... People who insist on 100% literal terminology might be well advised to steer away from ideogram-based languages and their writing systems, for there be dragons. You might notice - although it's hard to tell given your "therein lies the problem" - that no Cadmium is mentioned. Yes, noted. Although I have a hunch that we might be going to hear a little more about that soon. Stay tuned.

-

The Waive

A bot seemed to find its way into the site. I squashed the bot with Bender.

-

Z Restoration Progam

And therein lies the problem Galvanizing and Zinc plating are two totally different processes, the only thing they have in common is Zinc. If the Japanese specification is this vague then there will always be some confusion to what type of coating was used on the parts. Coming back to the Vintage Z restoration program of 1996-98 in the USA; Nissan Motor Corporation USA was very specific that Cad plating be used and listed it repeatedly in their "Quality Control Checklist". They also listed suspension parts be painted semi-gloss black not powder coated. There is no confusion here, it's all in black and white on the document.

-

Z Restoration Progam

So far it appears that cadmium was NOT banned in Japan in 1970. Therefore it is possible that cadmium plated hardware was available in the automotive industry in 1970 and early 1971. Carl Back has evidence apparently obtained from a very reputable high level technology company, Honeywell, that cadmium was present on the hardware he had tested from 240Z's. It's not clear how much. Maybe a plating bath was contaminated and there was just a trace. Mistakes happen, and sometimes deception. There are easily imagined scenarios where cadmium plated hardware could make it on to a 240Z production line, especially since cadmium was not banned and was still used in "more than 1,000 Japanese plants" in early 1971 . At this point the argument is between what Nissan's documents say, and what Carl Beck observed, and what general public documentation from the time period describes. That's the whole thing in a single sentence. All that I've done is add a little bit of clarity. Forum members can draw their own conclusions. The main point, Carl Beck's public service announcement, in a way, might actually be for people working with early 240Z hardware to assume that it might contain cadmium and to take appropriate precautions. Especially since the aftermarket appears to be offering cadmium plated hardware. Maybe Carl got some aftermarket bolts? Who knows. https://www.zeddsaver.com/pages/about-us https://www.nemetalworks.com/cadmium-plating-services

-

Z Restoration Progam

Let's take a look at the random example of a bolt from the front suspension. It's one of the hex bolts that holds the balljoint onto the transverse link. Part number from the 1970 Nissan C-187 Parts Catalog for the S30 and PS30 models is: 81-30820-65 BOLT WITH WASHER. Nissan Engineering Standard (NES) tables, the '81' prefix identifies it as a Hex bolt and the '65' suffix - when you look it up on the above table - shows us that it is Galvanized/Zinc Plated.

-

The Waive

Mike's removed them now but about a month ago there were some post in Russian that had nothing to do with Zs.

-

Bodywork Issues

That makes sense, but the problem is really just cosmetic (once I've confirmed that the exhaust problem has been corrected), so I don't think I want to go as far as adding a second strut to correct it. I don't think all cars with the single strut have raised driver side hatches, though, so I'm thinking that there are other ways to address this. If the hinges are worn, that might be a place to start, or maybe the two hinges just need to be adjusted relative to each other to lower the driver's side? At this point I haven't glued the seals back in or attempted to adjust the hinges or latch, so I think I'll move ahead with those steps and see how close I can get things to flush. The upper portion of the new inner seal is almost vertical when installed. When the hatch is closed the vertical portion slides outward against the underside of the hatch to create the seal, so I expect it to compress a little over time as well. As an aside, I was happy to see that, with a couple of careful initial closings where I manipulated the seal at the hinges, the seal is sliding over them properly. Both my original seal and the replacement were mangled by the hinges. I've been procrastinating on the next steps because I know I'm not going to enjoy removing the adhesive from the car before gluing the new seal in, but I'll report back when I've made progress.

-

Gav240z started following Z Restoration Progam

-

Z Restoration Progam

At the risk of flogging a dead horse. The fact that Japan banned cad plating and the fact that Nissan documentation doesn't mention CAD are two pretty compelling indicators of what was in use. Not to mention that when you find an old plated part that hasn't been exposed to the elements such as the AM radios chassis and you re-plate in yellow zinc, the finish looks pretty identical to original to me.

-

9shineslabel joined the community

-

-

The Waive

What's the problem?

-

Mitchel0407 started following Tire size. Confirm once and for all...

- Tire size. Confirm once and for all...

-

prostore@ix.netcom.com started following Tire size. Confirm once and for all...

- Tire size. Confirm once and for all...

-

dutchzcarguy started following Tire size. Confirm once and for all...

-

Tire size. Confirm once and for all...

I know these datsun 260z rims quite well and i would never go over 195/70R14 tires on these!! The 280zx has 6 inch wide rims and 195/70R14 tires on! The standard on 5,5 Inch rims is 185 and max 195 i would advice you! Best drive would be i think the todays 185/60R14 but then it leaves a bit of open wheelhousing.. I would prefer a good ride above a good LOOK! ;-)

-

Z Restoration Progam

@Zed Head Have you tried searching using the Japanese language? No, you're putting the cart before the horse there. How about 'Without a document explicitly stating that Cadmium-plated parts were used on these cars when they were made, the assertion remains anecdotal.' Aside from the issue of legislation, have you considered the elephant in the room here? Where does the assertion that the electroplating and protective, sacrificial chromate/passivate coatings we are discussing here were CADMIUM actually come from in the first instance? Where's the source? I've seen 'Cad' being referred to on this forum - and elsewhere - for many years as though it is established fact. Mostly from USA-based individuals. Where did that start, where did that come from? Can anyone provide any official data, document or communication from Nissan which talks about Cadmium electroplating being used on these cars in period? I'd be delighted to see it if such a thing can be found. Meanwhile, we have official, period documentation from the manufacturer - specifically relating to the S30-series Z - published Pro Bono for our use in maintaining the cars, which states that fasteners and fixings were electroplated with ZINC coatings. No mention of Cadmium. I posted an example of this, and you have - so far @Zed Head - all but ignored it. Any specific reason for that?

-

Round top SU carb piston binding

If you do one at the time you have a (mirrored) example there to see how it sits/comes together again.. and... ALWAYS make pictures BEFORE taking apart.. it's so easy to miss that sequence of the little rings/parts on there! RULE NUMBER ONE: MAKE PICTURES OF EVERYTHING YOUR GONNA RESTORE!

-

The Development Story & Specification Of The European Spec Datsun 240Z

The first versions were (as far as i know) never sold officially, but only delivered for testing as prototypes. Some ended up in private ownership. but i guess those were very few. The upgraded suspension, front and rear spoilers, 5-speed transmission and the different front turn signals, etc were standard equipment on all european cars. Even though the parts catalogue lists things as optional, as far as i know, most (all?) european Datsun importers didn't sell any dealership options and most cars were sold as standard european final spec cars. Aside from Portugal, of course, which had their own specifications.

- Tire size. Confirm once and for all...

-

w3wilkes started following Tire size. Confirm once and for all...

- Tire size. Confirm once and for all...

-

pjczc8 started following Tire size. Confirm once and for all...

-

Tire size. Confirm once and for all...

Hi All, Normally I can answer any question I have using all available sources on the internet but with this question I want to confirm with this community before pressing the buy button. I have a stock standard 1977 280z. I have purchased and reconditioned a set of 14x5.5 Nissan alloys (see pictures). I live in Qatar so tire choices are extremely limited. I can get some basic Yokohama ES32 in 195/70R14 if I want a stock black wall look. However I am tempted to import some BF Goodrich Radial TA's in either 225/60R14 or 205/70R14 at 4 x times the cost - because I love the look. My question is that with 5.5 inch wide alloys can I definitely get away with the 225/60s (which have a similar circumference to stock) or do I have to go with the 205/70s (which have a taller/larger circumference)? I have read a lot of people saying that 225s are OK, however I worry that they have 6 inch wheels not 5.5. At 4 x the price of the tires I can get locally I really don't want to get it wrong. Thank you for your help (and please feel free to share pictures in your response).