Everything posted by Jeff Berk

- Trouble-shoot directions for ignition/no start

-

Trouble-shoot directions for ignition/no start

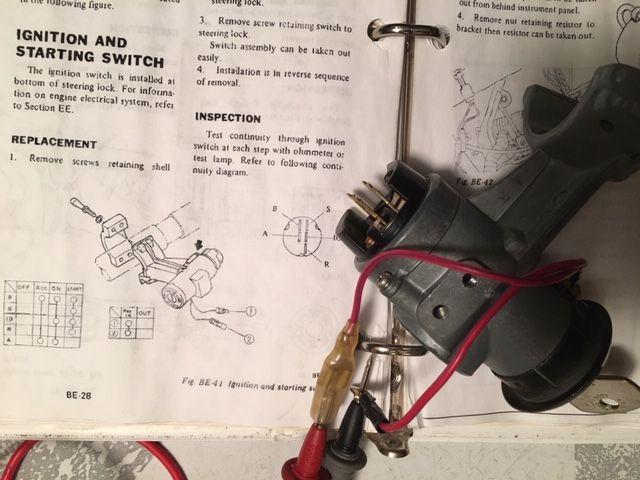

The pins tested out correct as per the diagram. I jumpered the solenoid to the battery and the starter spun like a champ. I connected a multimeter to the wire that connects to the small connector on the solenoid and it showed no power when I turned the key. I'm assuming that the two red leads don't need to be connected for the starter to start because I didn't bother since they only works the steering lock. My next step, I assume, is to see if power is going to the ignition switch. I have a wiring diagram so I'll start tracing.

- Trouble-shoot directions for ignition/no start

- Trouble-shoot directions for ignition/no start

-

Trouble-shoot directions for ignition/no start

Addressing the above questions... It has sat for 2 weeks outside while I worked on another car. It cranked lively like there was not problem other than forgetting to pull the choke the first time. Then utter silence when I turned the key. I hooked up a charger and it indicated that the battery was at 75% and I hit the "start" button on the charger to give the car more power for an attempted start. I turned the key and utter silence once again. The engine did not turn, the starter did not spin, and I don't think I even hear the solenoid click. The Unilite is a common problem but wouldn't of stopped the starter from spinning the engine, nor would a spark or fuel issue.

-

Trouble-shoot directions for ignition/no start

this morning I tried to start my 260z and the engine turned as normal, then I remembered to pull the choke, and nothing. I tried again and it once again turned not start. I released the key and tried again (it was a cold morning) and nothing. Again, nothing, and again. Where do I start? The battery seems fine but I put it on charge anyways. I didn't even hear a solenoid click (although it might of been muffled by my panic). Should I start at the ignition, solenoid, or is there something obvious (or insidious) I need to look at? BTW, it likely doesn't matter but I have a Mallory Unilite ignition.

-

Wiring harness issue? Maybe?

Do you have a wiring harness diagram http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/ You likely need to start at where you had the low voltage and work your way back to the next point to see what the voltage is. Be prepared for a slow tedious few hours.

-

Mikunis, but want a daily/recreational driver

Have you spoken to Lanny at R&R in Kent about the Mikuni's. https://www.facebook.com/510Restoration/

-

Parts Wanted: 1977 Datsun 280z Clock Wanted

The clock in my 260z didn't work when I purchased it two years ago and I went through two DOA e-bay clocks before trying to fix it myself. What I did was remove the back to see what makes it tick. I then determined that my clock used an electric motor to "wind" it, then it ran using a main spring. I sprayed it down with contact cleaner and put a drop of clock oil on every pivot point and plugged it in. It has been working ever since. I might of gotten lucky.

-

high idle speed issue

siteunseen... Thanks for the suggestion.

-

high idle speed issue

I just got word from the shop: "I’ve been talking to my camshaft contact. He grinds a slightly less aggressive cam for your car. The cam itself will cost around $450. We will also need new rockers and lash pads. They cost between $400 and $500 depending on what thickness pads are required. I’m looking at around 10 hours labor to remove and replace, and setup the geometry of the new cam. I will also change the oil & filter when I’m finished. So your looking at $1800 to $2000 if no problems show up after the cam is removed." I ask that he try to avoid having to do a valve job if at all possible since I'd be looking at an additional $500 or more.

-

high idle speed issue

The SU whisperer pointed to several potential contributing factors. The performance cam was milled from a CWC core. Apparently, CWC has a bad reputation. That engine should of had an internal oiler, but the cam shaft did not have provisions for that so an external oiling tube was installed. Since exhaust cams for 1, 2, and 3 cylinders were worn out, perhaps, the front half of the oiler tube became clogged.

-

high idle speed issue

I must of not aligned it properly when I rebuilt it. For some reason it was working fine for several months. The local SU whisperer knew what was wrong within a few minutes. Unfortunately, he also discovered that the exhaust cam on cylinder 3 was overly worn and I'm going to need to replace the camshaft. I didn't like that overly aggressive camshaft so now I have an excuse to replace it.

-

high idle speed issue

Problem resolved. I had a stuck butterfly valve in the front carb.

-

Ron Tyler (RT) differential mount dimensions

The only reason I'd DIY the mount is that I like to find a reason to use the metal shop I have access to and to make whatever parts I can for my Z. Looks like this will have to wait, just found out my camshaft needs replacing (ouch).

-

Ron Tyler (RT) differential mount dimensions

Could someone that has, or is knowledgeable about the Ron Tyler differential mount look at the dimensions of the mount on the listed URL and verify that it is valid for a Z application with an L28 engine/R200 differential? The mount was originally designed for a Chevy V8 conversion so I'm concerned that it might alter the driveshaft angle and put stress on the universal joint. I'm planning on building one using Alteredz.com as a guide. I'm assuming that RT has not patented his design. http://alteredz.com/drivelinemods.htm

-

Dash replacement—does this area need paint?

Working on your Z in the kitchen. You must have a very understanding spouse.

- S30 Chassis Jig and Sheet Metal Fabrication

-

high idle speed issue

I’m having a high idle speed issue. I’m running between 1,600 and 2,100 rpm. Prior to this, my 74z with a modified 280z engine running a pair of SU’s was having starting problems and would sometimes stall and idle somewhat slow. I decided to try and adjust the carb’s using https://zcarguide.com/tuning-adjusting-datsun-240z-su-carburetors/ Because one of the fist things to do was to check the spark plug condition and gap, I installed a new set of plugs. I’ve never adjusted the timing because I cannot find the timing mark (I have a gun and I know how to use it). I set the idle screws all the way out and then backed them in 1 ½ turns. Then it started right up with minimal cranking, but the rpm is too high. To get a balanced air flow from the pair of SU’s, I had to turn in the rear and back out the front SU’s idle screws. Doing so maintained the high rpm. There was a small vacuum leak from one of the ports on the vacuum balance tube that I stopped with some Teflon tape on the M10-1.0 bolt the PO installed. I couldn’t find any other leaks between the carburetors and engine/intake manifold. The fast idle adjust screw is out all the way. The vacuum activated dashpot between the carb’s not pulling the throttle open and the choke cables are disconnected. Could I be missing a vacuum leak or could the timing be too advanced? If so, how do I go about re-making TDC on the harmonic balance?

-

Fuel tank is out, Any opportunities to do something else?

I replaced the tank straps with stainless steel, but I had access to a free source of material and a community metal shop to cut them and make the end fittings so I was able to do it on the cheap. I also replaced several of the hoses because I found them to be hard. Braided fuel grade hoses are available by the foot because some German cars appear to use them. Make sure all your replacement hoses are fuel safe.

-

Long throttle linkage replacement

Does anyone make a replacement plastic end? Anyone try and print one on a 3-d printer or mill one out of aluminum? My short linkage is a little longer than the SS replacement being sold on e-bay and I wasn't able to get the seller to respond concerning a custom length. I figure a used one may or may not be better than what I have already. Jeff

-

e-fuel pump wiring cut

Steve, I decided to run a temporary wire to test the pump and to get the car running again with the intention of removing, inspecting, and re-wrapping the wiring harness over the winter. I re-wrapped several of the other wiring harnesses in the Z and found several melted wires that way. It turns out that the new pump works on the temporary wire but I wasn't getting enough pressure to easily start the car. That was resolved by replacing the mechanical fuel pump this past weekend. Thanks for the input. Jeff

-

e-fuel pump wiring cut

Hi all, My electric fuel pump is not getting power. There is power in the black/white wire off of the 2nd relay and I can trace power to the body harness connector next to the right side of the passenger seat. From there, it should go back to the pump but it never makes it. There is also no continuity from the body harness connector to the fuel pump connector. Given the option of either pulling out the wiring harness from under the interior panels or just splicing in a wire at the body harness connector and running it to the pump, which would be better? How much of the interior would have to be yanked to uncover the defective harness? Note that the car still runs with just the mechanical fuel pump but the pressure is less than 2 psi and the engine is running rough. 260z February 1974

-

Picking up a 1977 280z 6 Hours Away. Tips?

You might want to read this. Then after getting it to work, install a relay for your headlights. http://woodworkerb.com/home/datsun-240z-rebuild/blinker-detail/

-

Fuel tank hose with a hook in it (240-260z)

But the hose with the 180 degree bend (or two 90's) goes on the top tank connector passenger side, through the grommeted hole and to the vapor expansion tank. If that is correct, I got the wrong diameter hose somehow.