Everything posted by Jeff Berk

-

Need used throwout bearing

I am in need of a throwout bearing to build a spindle pin removal tool. As long as it can spin, I can use it. I am hoping to get one for the cost of shipping if possible. Thanks Jeff

-

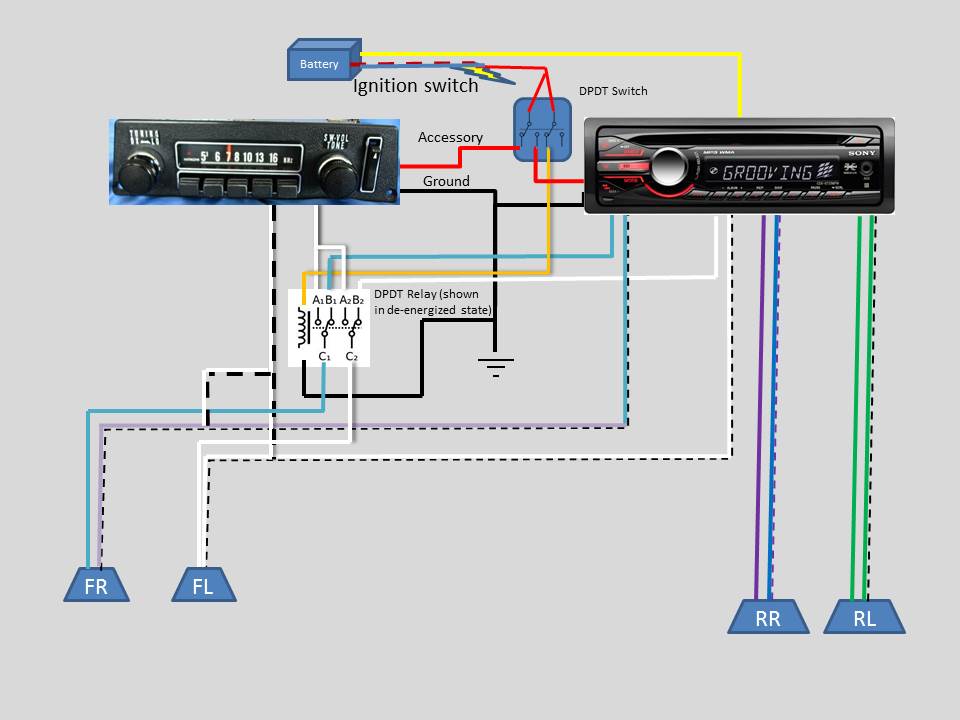

[SOLD] Original 260Z AM/FM radio and accessories - SOLD

I have one of those in my 260z but the lack of stereo was too much. I'm installing a modern radio in my glove compartment and a switch to go between the old and new radios. I had to use a relay to switch between speakers since speakers couldn't be wired both as mono and stereo at the same time.

-

Pay it forward!!!

Lumens... If you happen to have a '74 260Z manual you would like to pay forward, please contact me. There are a few sections of the on-line one that are too fuzzy to read. That or my eyesight is worse than I thought. (My mom told me to stop but I wouldn't listen.)

-

is removing the intake manifold risky?

Siteunseen: I already ordered the gasket from an on-line source. My local dealer is very unresponsive. I have a big bottle of anti-seize but I'm sure I'll never have to remove those bolts again (yea, right...). I'll likely work on rebuilding, polishing and clear-coating my carb's while I wait until for the gasket to arrive. Thanks to you and everyone else for help. Who know that a simple post "Is removing my intake manifold risky" would generate so much response. One more question about a hose connection on the front carburetor. There is an inlet shown in the center of this image (stolen from Datsunroadsterranch) to the left of the dome that allows air to enter the carburetor when choked: It was blocked off by a PO with a small rubber tube with a plug in the end. Should this be connected to something of importance? It seems odd that it's only on the front carb. Jeff

-

is removing the intake manifold risky?

I ordered an OEM using the parts number supplied by siteunseen. Thank you for the help. Down the rabbit hole I go...

-

is removing the intake manifold risky?

Any idea what gasket to get for an N42 head with an E46/E48 intake manifold? My car's a '74 260 but has a different engine and carb setup than original. I would of thought all the 240-280's had the same but that may not be the case. I'd likely not get an OEM since I need the option to return it if it does not fit.

-

is removing the intake manifold risky?

I just realized that the intake manifold gasket is also the exhaust manifold gasket. That being the case, I need to remove the exhaust manifold as well to replace the gasket, correct?

-

is removing the intake manifold risky?

I didn't know there was a clear coating you could apply to bare metal that was heat resistant. I'll read up on it but might go with Rust-Oleum Engine Enamel instead because I found it locally at Summit Racing. I got the last two bolts off and noticed that the inside of the intake is very rough. Would smoothing it out and polishing help performance or would it be a waste of time?

-

is removing the intake manifold risky?

I like that valve cover Siteunseen. Right now I have mine polished with Mother's. It's tempting to sand blast it to get that effect. Did you tape over the lettering or buff them out afterwards? I decided to pull my intake and started the project tonight. I seem to be one of those that likes to tinker with cars as much or more that drive them. I still have two bolts under the intake to remove that are difficult to get to. I found it odd that the lower bolts don't go through the flange but instead bolt to the block with wide washers that hold the lower flange against the engine. Nothing seemed overly tight so snapping off a stud or bolt is unlikely.

-

is removing the intake manifold risky?

Ok. Not worth the potential problem.

-

is removing the intake manifold risky?

I just rebuilt one of the two SU''s on my '74 260z and really like how it looks after blasting the body with glass beads. I'd like to do the same with the intake manifold but wanted to get some input on how much trouble I''m asking for in removing the intake (i.e. what is the likelihood that I'm going to break something like a stud in removing it). A local free access machine shop has a couple of blast cabinets available so it won't cost me anything. Note for those in NE Ohio, look up Sears ThinkBox at Case if you need to use machine shop tools, welders, etc. The only cost is materials and parking. Jeff

-

difference between two wiring harnesses

I had to change both the dash and fuse box harnesses but the problem ended up being due to a bad connection.

-

difference between two wiring harnesses

It worked out fine except for an extra wire. But then again, my original wiring had undergone so many modifications, I might of been missing that wire due to PO's re-wiring to install a radio or anti-thief system.

-

FSM Section EF for '74 260 needed

I have a 260z that has undergone may upgrades, downgrades and lateral grades. The carbs right now are 4-bolt round tops. Somewhere along the modifications, the return flow fuel line was disconnected and plugged. I'm getting vapor lock issues on hot days when I'm driving hard so I'd like to reconnect this line but I'm not sure where it goes. It is likely in Section EF (Fuel System) of the FSM; however, the only copy on line is a bit too fuzzy to read or to follow the diagrams. Could someone please pm me a copy of this section in a better resolution? Thanks Jeff

-

How do you get this off? Or does it come off?

I think you might want to get a tie-rod fork (a.k.a. pickle fork) from Autozone, Advance Auto, or whoever to separate it. They loan out these tools and you need just to return them within 30 days for a full refund of the deposit. https://www.homedepot.com/p/Powerbuilt-Tie-Rod-Ball-Joint-Separator-648468/204505272?cm_mmc=Shopping|THD|G|0|G-BASE-PLA-D25T-HandTools|&gclid=Cj0KCQiA_5_QBRC9ARIsADVww153tZZuaYVzwUjeTD87h7OVzBB9gakynvGAtcEwbrHDdULQWLN0hYsaAlwgEALw_wcB&gclsrc=aw.ds&dclid=CIGI0PLzudcCFQK7Twodco0HGg

-

Pay it forward!!!

Does anyone have a fast idle setting screw tab off of a 240z or 260z. I'm talking about that triangular piece that is attached by two screws and uses a third screw to push against the throttle linkage to increase the RPM for tuning the carb's? I've got a 260z with round tops so the setup is likely the same as a 240z.

-

Upper oil pan?

I'll give that a try after I wash off the underside. Thanks

-

Upper oil pan?

I've got an oil leak in my 260z (L28 engine). Not having a lift, I asked a mechanic at NTB to see if they could find the source using their lift. I suspected either a rear seal (I replaced it a few months ago) or the oil pan gasket. Instead I was told that the upper oil pan was leaking. What is an UPPER oil pan? From what little I could find on the net I know I need to remove a cross member to replace it and it uses RTV to form a gasket, but that's about it.

-

pilot bushing fit

FYI, I used dry ice to shrink mine so it would fit

-

Obsolete HTF Parts for Prototyping

Concerning the dash padding, it sounds like this device would work for anyone in the Cleveland, Ohio area but creating the model would be difficult. They also have a scanner with a 2-meter capacity, but I understand that 3-D scanning is not especially easy. http://thinkbox.case.edu/equipment/shopbot#centerCol Between the Cleveland Public Library's Makerspace and Case Western Reserve's Sears Think Box, there are a lot of resources here to create objects for roughly the cost of the material. Are their any detailed pictures of the 280z headlight connectors out there? From the few blurry photographs I've seen it looks like female bullet connectors embedded in a socket. That can't be that hard to make. The water-proof outer shell can be created using a flexible filament (e.g. NijaFlex).

-

Obsolete HTF Parts for Prototyping

I guess my question is what would you do with the design files (or whatever they are called) and the items generated by the prototype machines? If you create files that can be used to control a simple 3-d printer for example, would you offer to "print" the item for the Z community for the cost of material, for a fee that included the material and a profit (assuming the college permits commercial use of their equipment), or to sell or give the control files away to the Z community for their use on their personal 3d printers? I'm not saying that this is not a good idea, there's a video out of Jay Leno using a 3-d scanner and printer to create parts for his stable of cars and there are currently very few 3d printer files out there for Z parts. I'm just wondering what is the best way of using these resources. Jeff

-

Installing two radio systems (original in dash + new in glove compartment)

I’m trying to figure out how to hook up the original radio as well as a modern day radio in a 1974 260Z. The original speaker is gone and I have two door and two rear compartment speakers. If I chose to have the original (monaural ) radio power the two front speakers and still be able to run the two front and two rear with the modern radio, I’m assuming I need to do some special wiring since both radios cannot power a speaker at the same time and since the two front speakers cannot be hooked together for the original radio because that will be a problem for the modern radio that needs to keep them separate. Please look this over and offer suggestions on if it will work or if there is a better way. 1) Power from an ignition controlled source goes to a DPDT switch that toggles between powering the original radio and the modern radio (red line) and a power feed to a DPDT relay (orange line) or an open circuit. 2) The original radio on the left has two speaker wires, the positive wire (white) and the negative wire (white with a black dash). The negative wire splits and goes to both rear speakers. The positive wire splits and goes to contacts A1 and A2 on the relay. 3) The modern radio on the right has eight speaker wires with the rear speakers wires (green and blue pairs) going to the two rear speakers (RR and RL). The front speakers have two pairs of wires with the two negative wires doing to the two rear speakers (turquoise and white with black dash) and the two positive wires (turquoise and white) going to the B1 and B2 connectors on the relay, respectively. 4) Assuming A1 and A2 are open in the de-energized state, the speaker signals will travel from the modern radio through the turquoise to B1, then to C1 and then to the front right (FR) speaker and through the white wire to B2, then to C2 and on to the front left (FL) speaker. 5) Assuming the relay has been energized by the DPDT switch which is sending power now to the original radio, A1 is connected to C1 and A2 is connected to C2 in the relay. This will send the speaker signal from the original radio to a split connected to A1 and A2 so that both front speakers are powered. The above assumes that it is OK to have the negative wires from the front speakers connected to both the original and modern radios at the same time and for the negative front speaker wires to be interconnected. I might be able to find a relay that has 4 internal switches, but that might be hard to find.

-

proper routing engine harness and dash harness

Actually, your's looks not that bad. I'm glad you have some of the wires labeled (#4 in the second shot). You might want to tape wrap some of the wires together that are going to the same component groups. Also I see some relays dangling. I 3D printed a relay holder for my two flasher relays to keep them out of the way (public library has several 3D printers). There are a number of metal bend tabs that are used to hold wire harnesses in place. See if there are any that you could utilize that could help organize the wires. If nothing else, no one will be able to see the wires once the dash is put back together. Remember that this car pre-dates cars with circuit boards and ribbon cable so there will be a lot more wires strung behind the dash.

-

Heater Fan has power/not working while in car

OK!!!!!! I think I'm there...THANK YOU CO I went to Autozone and picked up a new relay and wired it in, adding a ground wire since the new relay had a plastic shell. So far it seems to be working. Now to secure the wires so it doesn't look jerry rigged. Now onto the next electrical glitch.

-

Heater Fan has power/not working while in car

CO: I removed the relay cover and one of the points looks rounded. I lightly sanded them with fine sand paper (wish i still had my points file). With the ignition OFF/fan OFF/Relay installed: There is 12 volts between the diagonal G & L wires while back probing. Therefore there must be continuity. With the ignition at ACC/fan OFF there is no click, points are open, between G&L 0 Volts, 37 ohms. With the ignition at ACC/fan ON there is no click, points are open, between G&L 10.2 Volts. A relay is inexpensive enough, maybe I should buy one. As a side note, I found that plugging/unplugging the relay blew a fuse but not the one for the blower motor. For the dash lights (not working right now) and the voltage regulator under the hood. Jeff