dutchzcarguy

Free Member

-

Joined

-

Last visited

-

Currently

Viewing Topic: Z's on BAT and other places collection

Everything posted by dutchzcarguy

-

79 280zx windshield trim removal

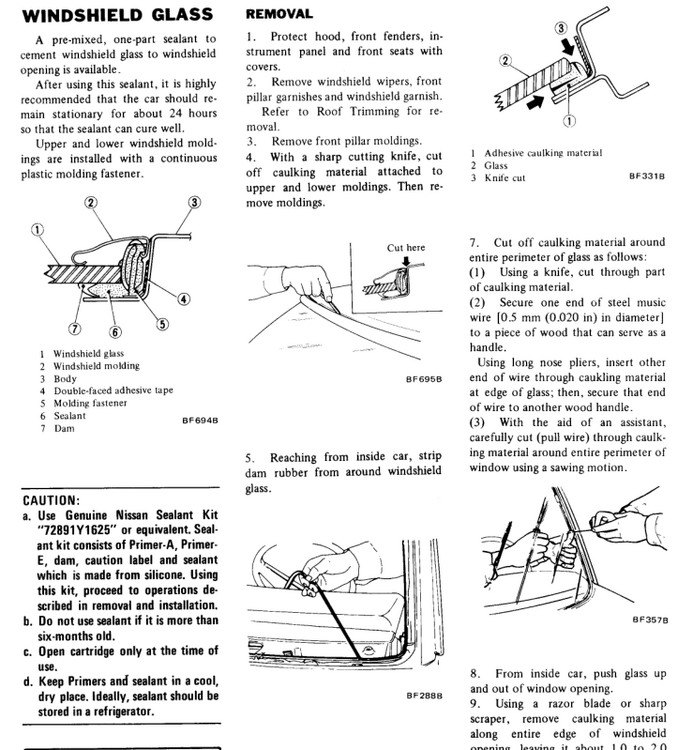

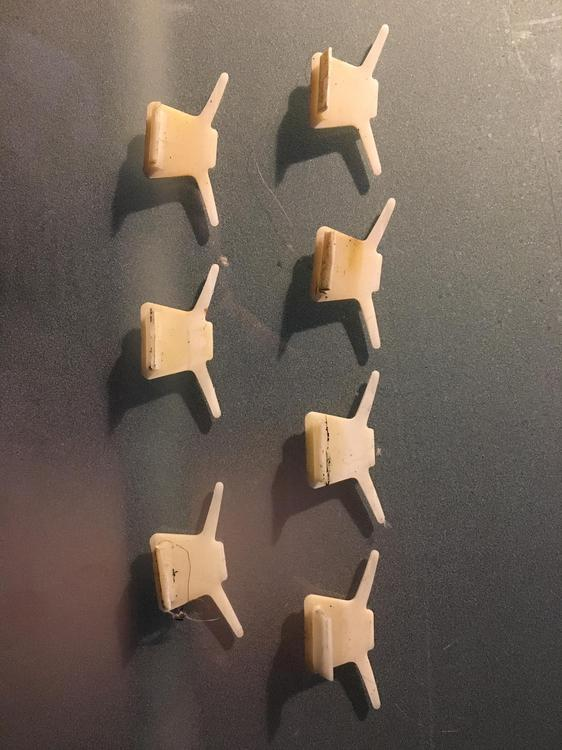

Eèèhhmm.. A 280z and a 280zx are completely different.. A 280z has a rubber all around the windshield like a 240z has.. A 280zx windshield glass is glued to the car.. It's much modern way to place the glass, it's part of the construction now. In picture BF694B You see the things you need.. As these parts are no longer available you can use the today's much better sealant. What you need to save from the old window are the parts i send you a picture of in #5 .. They hold the chrome strips on theire place. If they are broken too you can use some sealant there as well but when you need to replace such windshield it's a pain in the **** to replace..

-

saturday night music thread

Good one Site! Didn't know that title but the number i know very well, i listened till the end! Much better than all the sh*t they (almost everyone else) are making lately hahaha...

-

79 280zx windshield trim removal

I see this a bit late.. but i have done this without destroying anything.. i believe.. See my restore of a 1979 280zx2+2 slick roof.. and yes you start in the doors removing stuff to remove the front glass trim.. Don't forget these parts you need for the new glass... see comment 100 on above mentioned topic.

-

I've Seen The Future

Hihi.. What does one say when you want the car to continue? Engage? (Captain Picard!) 🤣

-

1973 Rebuild

Hihi.. I would like to see that one to! Hihi.. i don't remember i ever have seen one. A 240z has a fuelfilter under the hood.. that's it.. Other (later) s30 and s130 have a electric pump and a filter in the rear (and a puls dampener for the electric fuelpump.) For as far i know..

-

I've Seen The Future

Nice opportunity! Could you talk to the car and tell him the adress where you wanted to go or? It remembers me of a cardealer that had a show and he was looking for someone that could drive the new (then) Honda accord, He said he was looking for someone to drive the powerfull car and he knew me as a zx driver.. We took off, him in the passengerseat.. At one point we came to a trafficlight with a few cars already waiting for green, As i approached fast i took a swing on the steeringwheel and went for the right turn lane and he thought i would hit the waiting cars! He Braked like hell on a empty floor Hahaha.. And i said in a calm tone: It isn't easy to brake without a pedal, while i turned to the right taking the car onto the highway! That was FUN! I didn't buy the car but we had a nice ride!

-

1971 HLS30-14938 "Lily" build

I had the same thoughts when i needed to do my 280zx chrome strips.. (I'm not gonna polish them on a bench polisher.. i already saw the parts fly around in my mind) You could "glue them temporary to a piece of wood with some (small "blobs") silicone, wait a day or 3 and polish the hell out of them.. then take a wire and get them off the wood and clean out the silicone on a clean towel.

-

Half shaft rebuild. What could require that?

The older half shafts have a little screw inbetween were you can put a little nipple to grease them. then put the little screw back. If they have play it will soon get more.. replacing the needle bearings in a halfshaft takes a lot of your patience i learnt..haha..pffff... use lot of grease to hold them in place.

-

First three cylinders are lean,,,, but not sure why?

I always have to watch out that my 240z is not going over the 6500rpm's! it wants to go over 7K! And yes the carbs should be around 2,5 turns out. Also check for air leaks and do a ignition timing check.

-

Restoration of BringaTrailer 240z - HLS30-35883

They were for tying the cars down and the dealers were supposed to take them off before delivery to the customer, but as they were a bit lazy.. they were left on.

-

1971 HLS30-14938 "Lily" build

Ah, Thanks! We call the number 30 contact (were the signal go's in the switch the P-contact.) Also the common. 30

-

1971 HLS30-14938 "Lily" build

YES! That circuitry is what we electronic guys call the famous flipflop.. You have to experiment with resistors and capacitors and make one resistor a potentiometer (and a small resistor in series) to make a variable timer.. I believe you guys call it a bread to test on? You can make all kinds of electronic circuits on a testbread. I took a short look at the circuit and in that one you can change one of the LED's for a relay of 6 or 12 V that switches between 2 contacts (My translator says change over contact but that's not a very good translation..) Tutorial 1: Building a Circuit on Breadboard for Beginners in Electronics (startingelectronics.org) In the 2 contact outputs of the relais you put on one of them a high power variable resistor ( as a potmeter but high power=expensive..) for the lower amp's Hope you get it hihi.. It's a nice way to study a bit of electronics making your own circuitry, if your not really interested, i think it's to difficult for someone that never worked with small electronic stuff..

-

1971 HLS30-14938 "Lily" build

With a "flip-flop" circuit you can find on the internet you can make a 1-100 sec flipflop (Pot-meter on it) and a relais that switches on command of the flipflop circuit and the relais switsches a resistor into your passifying circuit on and off.. Now you have 2 diff. currents going to your parts.. The resistor inline with your parts need to be a power potentiometer that can handle the currents.

-

Restoration of BringaTrailer 240z - HLS30-35883

I felt addressed there hahaha.. my nickname could be Overfastener Mart haha.. 🙊 (I used to overfasten.. not anymore.. use torquewrenches!) Mart (short for Martin)

-

Z's on BAT and other places collection

Already $3200 and 6 days to go! (I keep my Hitachi's for sure! 😉 )

-

280zx turbo ECU with side mounted potentiometer

I think all the injectors have a resistor inline. They are normally in the corner of the engineroom on a aluminum cooling block/frame. I wondered always why there are 6 transistors to open the 6 injectors.. they all open together at ones.. at least the non turbo's do.. They all inject at the same time independant of when theire cylinder needs the gas.. Also.. normally you can NOT put 12 volt on a injector, it will get damaged direct on a car battery. You CAN test them with a little 9 volt battery you find in those firedetectors and remotes or so. They don't have the current to hurt the injector, just give the injector a pulse with the 9v battery, if you ever need to test one. (Put also some carbcleaner in the injector when you do!) Btw.. did you test in the video without injector-resistors ?? I would think that's lethal to the injectors!

-

280zx turbo ECU with side mounted potentiometer

Hi Dave, Nice to see these ECU's opened up.. I did last year a Non turbo.. they are completely different.. I would mot worry to much about the capacitors.. yes maybe the electrolite ones there are a few but the parts nissan used in these ecu's are high standard. I understand that the problem you have is that it will not rev above 2000 rpm's ?? Maybe the ecu get's foulty signals and want's to protect the engine.. As an electrical engineer i think it's not your ecu that's the problem. You should check the signals it's getting from the engine.. If the other "new"ecu is from another 20e (turbo?) then it could work also it's just that there may be some differences in rpm points were the 2,8 ltr go's not or even further with injecting etc etc.. Btw, nice test stand! Mart.

-

Restoration of BringaTrailer 240z - HLS30-35883

I bought some OEM ones in 1994.. They stayed in the "warehouse" till 2000 and used them on my 240z. After about 20 years so around 2020 one of the brakepads came lose on one brakeshoe! They were original nissan as i ordered them myself at nissan. So they don't last forever.. But hey who knows how old they were before I got them.. Btw.. no fun having some lose parts in your drum, Luckely i was just 100mtrs from home and went back and installed some other ones.

-

Small rust thru spots on drivers side floor 72z

Yeah.. why not.. i was only looking for the name of those rubber thingy's you put in the nice round hole(s).. But first i would clean the complete floor as there are often more holes than you think.. My first 280zx had had every 2 years a new layer of undercoating.. when i had it 10 years it was about 20 years old and the technician that checked my car for MOT (Dutch=APK) said to me he could poke right through the bottom at 17 places or so... It had rotted from the inside.. I never needed to put some undercoating on it.. it had a layer of half a cm.. personally i hate undercoating.. grease is best i think, it wipes off and you see more through it when something is wrong. My latest 280zx has some kind of "silolak"on it.. it's not done by me.. but it's increadable stuff. I ones took of a little bit on the brakeline and after 40 years the original greenish paint nissan used on them came from under it.. in unbelievable good condition. I wish i knew what the pre owner used. Silolak=silolacquer.. "Silolak" in english can be something like: paint for silo's? My translator program just says silo for a silo.. it's a big round standing up tank for pig or chickenfood.. a silo.. long ago they were made of steel and they rusted like hell as some foods can attack the steel.. so they had made a paint called silolacquer

-

1973 Rebuild

Looks good but i hope that stripe just above the middle of the picture in the lip of the coolant/thermostatholder isn't a crack? 🙊

-

Small rust thru spots on drivers side floor 72z

Oh Ps.. My 240z is very flexing.. More and more rubber! (Just kidding!)

-

Small rust thru spots on drivers side floor 72z

An easy way to get rid of those holes.. Take a holesaw and.. as you can't center them with the center bit.. first make a hole in a flat piece of wood and then hold the wood over the hole in the floor of your z.. then dril a nice round hole out of the bad rust hole.. ad a rubber lid in the hole and your ready! 😉 check the rusty hole for what diameter drill you need. NO welder/welding needed.

-

Hatch misaligned?

Take it off (Big JIS screwdriver needed) and listen during a drive if it's gone. wouldn't surprise me if it's still there! My 240z squeeks and rattles all the time.. These car body's do a LOT of warping during driving in the length of the body.. it's normal. I found that the Inner lining around the roof (Those plastic covers) are a "nice source" of rattles and squeeks.. You can get rid of them by using a little grease or WD grease product. Maybe some polishing of the plastic parts will also do the trick. Let us know what you found.

-

A couple of SU questions

How about the original servicemanual? 😁

-

Door lower weatherstripping 280z

Hahaha... I do drive in the wet.. but my sill aluminum strips are lying in my sellar (also known as the big pile of parts store!) So they don't get wet! I drove my 240z most in the winter as i really really don't want to restore a 300zxtt !! (A 240z restore IS MMUCH simpler!) As for the noise dampening of the strip under the door.. haha.. i hear my engine and (not really original) exhaust drowning out everything, so i'm not bothered by a little ambient noise.