Everything posted by Zed Head

-

Saridout's 1976 Color Wiring Diagram

Hello Mike. I'm not sure where Saridout has been but I'm fairly confident that he won't mind if you download his diagram to the Downloads section. I actually had some correspondence with him a few months or a year ago about the broken links to his web site and he sent me a new link that worked, for a short while. But Eurodat has also downloaded a copy in to one of his messages too. So, it's there and we might as well make it easy. It's a nice piece of work. Post #27. http://www.classiczcars.com/topic/33820-free-full-color-wiring-diagram-for-1976-280z/page-2 Edit - seemed like a year but I guess it's only been about 8 months.

-

Dim Headlights

The Irwin/MSA product is a good one. I think that it does both the power supply side and the ground side so cleans up both of the problem areas. If you feel comfortable with adding a relay, you can add one in front of the combination switch, at the fuse box, to take the power flow out of the switch and let it come through the relay instead. I can't remember the details but it should be apparent from the wiring diagram. You only need one to supply the fusebox, I believe. A link is supplied below to Saridout's very nice 1976 color diagram. Post #27. Besides dim headlights, the other problem that will crop up is heat buildup in the steering column switch. either the heat cycling and fatigue, or actual melting of the solder, happens (hard to tell which, shiny metal is exposed) and the wire will break off at the contact. You'll know you have this problem if the top of the plastic column cover gets very warm when the headlights are on. The actual switch is under it. http://www.classiczcars.com/topic/33820-free-full-color-wiring-diagram-for-1976-280z/page-2

-

Vogtland springs

Thanks for checking. I don't want to give jdmwerks a bad rep. I've seen where people had no problems with the 280Z setup and liked it, and just one where a guy had a problem, but jdmwerks resolved it quickly. But you never know what other parts people are working with or what they're really doing. Hope yours drop right in.

-

Recommendation for new radiator and elctrical fan for 280Z

The dash voltmeter is a good indicator of whether or not your alternator is keeping up. Note where it sits with everything off. That's your base battery charge reading. Then, after the engine is started and running at higher RPM you'll see it jump up to some high limit. That's the alternator regulator limit. As RPM drop toward idle speed you'll probably see the needle drop toward the normal battery charge state. When it hits the number, that's equilibrium, power out = power in. If it drops lower your battery is discharging. The gauge isn't very precise so you'll probably just see it sitting on the everything off state. You'll feel good when you're driving and worried when you're idling. Many people have used the early 90's Maxims alternator. It's a 90 amp output and will bolt in. But it needs a pulley change and rewiring. Simple in concept, but the pulley bolt needs an impact wrench and some grinding of the housing might be needed to get the pulley aligned. I have one sitting in my garage, completed, but I've found that the small improvements here and there, relays and connection cleaning, have put my stock ZX alternator to where it can keep up, with my stock electrical parts, no fans. I've also found that the cheap parts store alternators vary in their output. The first one I used was weak. The factory issued, old, grimy, wrecking yard ZX alternator was much better than the shiny "new" parts store reman.

-

Heater control panel

The disassembly is described in the 1976 AC chapter. AC-31. And, of course, assembly is in reverse. They say have the cables on the control assembly (plate) first. So zKars's method is best. It is possible to remove at least some of the cable ends, maybe all, from the assembly though, with it installed. But you do need some slack in the cable so that you can maneuver it without bending it. If yours is already done backward you'll know pretty soon whether you need to take it apart again.

-

Heater control panel

Not really clear what "hvac plate" means. Or "heater box". I've detached and attached cables from both ends. Sometimes it takes some contorting and a little extra maneuvering, and don't lose the little clip, but I think that the cables could be installed last if you wanted to do it that way. Edit - the ends of the cables go to the water rooster on the firewall, and the foot vent doors. That's why heater box is odd. I haven't worked with the vents so maybe that's the heater box.

-

OK to lift 280Z by the control arms?

Probably depends on which part of the control arm was used and how wide and distributed the lifting pad was. The ends, under the struts, probably not a huge deal. In the middle, not recommended. But, definitely not designed for it. People these days just aren't trained in how to work with stuff bigger than a phone. Are there visible bends or dings in the arms? You probably should have been emphatic and left the shop when they resisted. Lifting a car is basic shop knowledge. I can't even imagine being told I was wrong when someone was working on my car. The customer, etc....

- 280z Fusible Link Upgrade

-

Vogtland springs

What do you mean by "they are all four the same"?

-

Vogtland springs

In that other thread the guy was switching springs back to front to try to figure out his problem. Since one set gave the height he wanted, jdmwerks sent him another two of the same so he'd have proper height. Which was good of him. That might be the new normal, maybe there's a problem with some of the springs. But, there is still a question...

-

Vogtland springs

I saw on another forum that somebody had a problem with one of the part numbers. The spring had the wrong rate for some reason. They swapped one for the other so the guy ended up with four of the same. Not sure how it turned out. It's tough to introduce new products. Hope he figures out what's going on.

- Recommendation for new radiator and elctrical fan for 280Z

-

280zx distributor spacer ? - into 71

The ZX distributor uses the one like in Post #4. "L28E" in Post #11. I just checked mine. Plus that picture in #4 is from Blue's ZX distributor upgrade page on atlanticz.

-

Stainless steel headers, exhausts and JDM twin-pipe mufflers.

What is the difference between the products, besides the pipe size. Just curious. The Race-sport and Street-sport especially. Good luck with the business.

-

Pulse Width Modulated (PWM) Dimmer Control Upgrade

That looks pretty cool, but................why? Does the current (no pun...) system waste that much energy or are you just running out of things to make better? PWM implies some microcircuitry. Is there a computer in that little box? Pretty far out. If I could get my potentiometer out I'd be on-board with it. It's way up in there though. You seem to be making a lot of brass extendo devices...

-

280zx distributor spacer ? - into 71

There's no picture. And most people use "tang" to describe the piece at the end of the oil pump shaft, down in the hole, that fits in to the slot on the bottom of the distributor shaft. So not sure what you mean by tang. There are no threads on the tang. Or "spacer", since there's no spacer on the distributors. Maybe you meant mount or base. The ZX distributors do definitely need their own base, that bolts to the front cover. http://www.merriam-webster.com/dictionary/tang

-

Current Coilover Options For 280Z's

Patcon makes a point. I was being "literal" in car slang terms. Since the factory struts are "coilover" by definition. Here's a setup that people seem to like - http://brandcarparts.com/shocks-struts-nissan-280z Bolt-in. Inexpensive. Vogtland springs for lowering and a couple of shock/strut options.

-

Current Coilover Options For 280Z's

I went back and read the fine print and see that you're right. There's a thread on Hybridz about them, from JPN.

-

Current Coilover Options For 280Z's

Didn't realize that JPN and BC are the same company or JPN is distributing BC parts. Kind of confusing.

-

Recommendation for new radiator and elctrical fan for 280Z

I've looked for a good switch for a fan in the past (it was for an injector cooling fan, not radiator). Difficult to find. The ZX switch is set to a high temperature, it's more of an extreme heat switch, to battle the heat-soak problem. Probably wouldn't work well for radiator cooling fans, it turns on at 210 F or around there. I think that many people who use the electric cooling fans use programmable systems, with a thermocouple. Here's a general article. http://www.hotrod.com/how-to/engine/ccrp-1111-electric-radiator-fans/ Good luck on matching the thermostat housing threads. Most people just run a tap through the hole and repurpose it. Once they find a sensor that they like.

-

Current Coilover Options For 280Z's

Maybe the web site needs updating but they don't show a 280Z option. Only early S30, 240Z - 260Z. http://www.bc-racing.co.uk/applications/nissan-coilovers/nissan-240z-260z-51mm-strut-70-73.html http://www.bc-racing.co.uk/applications/nissan-coilovers/nissan-280z-260z-with-55mm-strut-75-78.html

-

NGK BPR6ES plug cap coming loose warning

I've seen the problem in the past but have noticed that the newer NGK's I bought have a different color electrode (darker, not shiny aluminum) and it doesn't seem to come loose anymore. Almost looks like the flange is part of the "cap" now. The issue might have been addressed with a modification. Could also have been a short-term problem caused by a manufacturing change. And there's always thread-locker. The threads are metal-to-metal contact on one side so conductivity isn't an issue. Plus contact with the flange.

-

Current Coilover Options For 280Z's

One negative of the T3 product might be the cost of the shocks. Koni's are expensive. If you can do the work then just buying an adjustable spring perch (basically a threaded tube with a perch on it) and sectioning would give you the most basic thing people look for, adjustability, pretty cheaply. The key to success is understanding that the sectioning is for getting the shock to fit properly and work within the desired range of travel. Choosing the shock is a result of choosing ride height and finding one with the range of travel to fit that ride height. The spring perch can be installed on any tube height. Basically answer the questions of "why am I cutting the strut tube to be this length", why am I using this shock, what is the purpose of the adjustable spring perch, where does the perch need to be with the springs I plan to use. Even if you buy a package or kit, it's good to think about those questions. People occasionally miss a question and end up with bottomed out shocks, or a car that sits too high or too low at full spring perch adjustment. Wheels factor in also since they affect ride height.

-

Very Cool Ignition Upgrade

It's fun to make things better. But the 123 ignition system has been around in the 3 ohm primary circuit form for many years and probably many miles. Seems like a design problem would have shown up in that time. Maybe you just got a bad cap.

-

Weird Wiper Issue

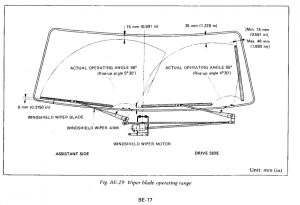

There was a guy on another forum who had installed the linkage at the motor 180 degrees off. His wipers worked but they tried to park on the hood. Maybe you're seeing the wipers move and park but what you're seeing out of the cowl area won't work once installed. Anyway, here's a drawing of how things are supposed to be.