Everything posted by Zed Head

- Bad Brake booster

-

Gas Tank Filler Cap Problems - Threads Stripped

I built a filler tube insert using three drilled holes and set screws, to clamp it to the inside of the original tube. Yours is pretty messed up though and you'd need to find a cap that would seal on the old tube's top. A rubber plumbing pipe cap and a hose clamp might get you by, with a small hole poked in it for a vent. Or a rubber hose coupler to clamp a new tube to the old one. You won't be able to close the outer cap though. Kind of joking. Dropping the tank is the way to go. Shouldn't have got angry...

-

Build Thread - New Turbo-Swapped 280z from WA

I like this one since it leaked without the engine running. The oil just sits below the edge of the pan when the engine's not running. The only seal it can get by is the drain plug's. If you ran the engine then turned it off and let it sit, the filter gasket is a potential leak area,, since it's tilted and is supposed to stay filled.

-

Dreaming LSDs

Attribution... http://forums.hybridz.org/topic/49194-differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount/

-

32K mile 1976 280Z Original - Survivor

I noticed some people on BAT commenting about the sill plates not having "Datsun" in the middle. My 1/76 build car does not have Datsun on the sill plates. It's been painted once, poorly, but everything else about the car says it's original. Maybe they don't know what they're talking about.

-

Overheating after modifications, what am I overlooking?

So, what I implied was normal is probably actually a sign of a clogged/low flow radiator. I saw this on my old radiator, which didn't cause overheating but had problems keeping temperature down on the hotter days. It was marginal. Interesting too that the suddenness is most likely the T-stat opening, like you thought. More clues for future cooling problems.

-

Can't get timing to less than 25 degrees?

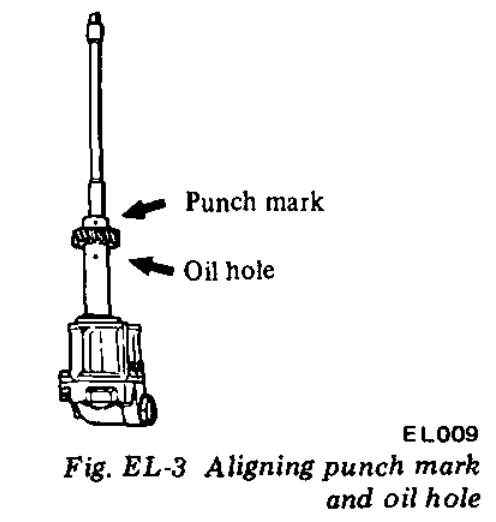

The locating dot/divot looks kinda like a pin, but it's just a shallow depression in one side of the gear body. Nothing on the other side.

-

FS5W71B 280zx transmisson rebuild

The USPS is pretty fast. Fedex and UPS seem overpriced now..

-

Can't get timing to less than 25 degrees?

I'm tempted to go drop the pump on my seemingly all original 76 short block. It's just sitting there wasting space anyway.

-

Can't get timing to less than 25 degrees?

Just regurgitating stuff I've read, from people who seem to know. Maybe they all pinned theirs before you saw them. Here's another. http://forums.hybridz.org/topic/106792-slop-in-the-distributor-drive/

-

Can't get timing to less than 25 degrees?

Hope your fingers don't get tired or cramped... I didn't post it earlier but the gear on the oil pump is apparently a press-fit. They've been known to slip. There are stories about the gear slipping upward, causing the distributor drive slot to lose contact with the drive tang, or just spinning a bit and screwing up the ignition timing. Something to consider if it changes again. http://forums.hybridz.org/topic/115353-l28et-issues-oil-pump-shaft-gear-spun/

-

Flow Rate and P/N Of Original Factory Injectors

Here's some internet fun. I took one of your Bostech pdf file numbers and Googled it. I got some 280Z references. So I put it in to the CourtesyParts site and it comes up, but is discontinued and undefined. Looking like Nissan did not identify more than the package for their injectors. Lose the paperwork or package and it becomes unknown.

- Overheating after modifications, what am I overlooking?

- Overheating after modifications, what am I overlooking?

-

Overheating after modifications, what am I overlooking?

Could be. The top hose supplies the top "tank" of the radiator, from there the coolant has to flow through many small tubes to the bottom tank. The small tubes are what get clogged. Looks like you might have went past well-enough. Might not even be the thermostat opening, but if you wanted to test, you could remove the thermostat. Then you'll get immediate problems.

-

Flow Rate and P/N Of Original Factory Injectors

Yours don't have any numbers or letters molded in to the plastic at all? No A46......1? The colors fade over the years. I have a bunch of old injectors. Here's a picture of one of a set of six, that look awful but were perfectly balanced on my little full-rate wide open flow tester. The other side says Made in Japan. I had them on my car for a while but took them off when I started trying to solve the heat soak problem. They're still on the rail. They came from my 1978 parts car, the rusted hulk that keeps on giving. I have some of the Bosch injectors also. You can have either of them if you can use them.

-

Under hood help (260z)

Nissan actually define it better than just "vapor lock" or "heat soak". They wrote a thing about it.

-

Dreaming LSDs

7tooZ's offer is worth keeping in mind. The MFactory product is apparently of high quality and I think that 7too had his professionally installed in an R200 housing. Properly shimmed, new bearings, seals, etc. It's a drop-in R200 long-nose, which is what the 87-89 300ZX clutch-type LSD would almost be. No need to change the pinion flange with 7too's diff. Drop yours, install his. Not clear what you mean by housing plate or (E) mounts. Maybe you left a picture out? There are two types of R200 - long-nose and short-nose. The transition from long to short was 1990.

-

A Real Shocker!!!

Hydrogen is explosive at very low concentrations and doesn't take much to ignite. There's some good reading out there about it, I posted one below. I had a friend check the electrolyte level of somebody's battery with a lighter. The gases lit up in his face. They threw him in another car and drove over a couple of curbs to get to the water hose at the gas station to rinse his face off. That was back when water and air were free. It was Saturday night, cruising night, at the shopping center parking lot. The old days, when we didn't have "phones" to keep us occupied. https://www.nasa.gov/pdf/513855main_ASK_41s_explosive.pdf

-

Flow Rate and P/N Of Original Factory Injectors

I have to confess that I might be the one that connected the range of Bosch part numbers together. I have found many of the 0 028 150 116's in the local yards on 280ZX's, back, 5 years ago, when the yards had a regular supply of Z's and ZX's. I ran a set on my 280Z for while until one sprung a leak (they're on the shelf, waiting for me to find that one replacement. Even though I don't even use that style any more). I think that all of the evidence I've seen has been anecdotal, like Fast Woman's story, and my wrecking yard finds, and my projections are based on those and data like the Stan Weiss table, and Chickenman's comments. There's got to be a cross-ref list out there somewhere.

-

Flow Rate and P/N Of Original Factory Injectors

Here's a link to one post in that ancient blog. The links to the source are at the top if you want to dig through more. It's on-topic but doesn't cover your question. Search "Bosch" in it and you'll find a good post from a Ford guy. Even Ford was color-coding injectors back then. http://yarchive.net/car/injectors.html

-

Flow Rate and P/N Of Original Factory Injectors

Here's a typical general reference, below. I think that finding Bosch injectors in your 280ZX is like finding a 10 ohm resistor in the coolant sensor line on your 280Z. Somebody like us either figured things out back in the 80's or a cross-reference list existed. I am 99% certain that Bosch changed their part number with the length of the hose. I think that the range ran from 105 to 120, as you can see in that spreadsheet. Until somebody finds that cross-reference, there will be no certainty, beside the reality that many people use them and that they work very well. I have another old source I can paw through, from a guy who who really understood the system, even suggesting modifying the AFM traces to tune it. He might have mentioned something. I'll have to dig it up though. It's good reading.

-

Dreaming LSDs

It's all about cost, skill, luck, and time. How much of each or any or any combination, do you have? Here's an option that looks quick, fairly low skill level required, but expensive. https://whiteheadperformance.com/performance-parts/datsun-240z-260z-280z-1970-78/240z-280z-diff-differential-axles-lsd/

-

Bought # 4858

No advice, just curious, but how bent is the head? The head on my 76 engine was bowed up in the middle about .008". I set it back on with no gasket and found that I could pull the bow down really easily with a single head bolt and a ratchet handle. Seems to me that having a bent head machined with a torque plate then bolting it to the engine to run it straight makes more sense than shaving material to get the surface flat but the valve guides off axis. Just a thought. I wonder if the requirement of straightening is really required. I never re-used the head so have no evidence either way.

-

Dreaming LSDs

There's this one - http://forums.hybridz.org/topic/127169-mfactory-r200-helical-lsd/ which seems pnp. Then there's the OBX, which takes some work to make sure you get the right one, and flip the gears, and replace the low quality washers inside. https://www.amazon.com/OBX-Helical-Nissan-300ZX-Silvia/dp/B00QHQWMQ6 http://forums.hybridz.org/topic/88099-obx-differential-inspection-and-installation/