Everything posted by zKars

-

Oxygen Sensor In Cast Iron Exhaust Manifold

81-83 280zx turbo's have an O2 bung in the cast iron down pipe out of the turbo. I think starting in 80 or 81 the NA engines had one too. The 81 FSM EF-43 shows its location.

-

Oil Pressure Sender

BSPT. There was a semi recent discussion about this and the source for adapters. Some, including me, would argue no "need" for correct adapters. I ran an 1/8 NPT tap into the oil sender port, added my NPT "T" (using an oil pressure safety switch along side sender) and never looked back. Stock oil sender threads happily and leak free into NPT as well. I've had mine this way for years and years with 0 leaks. Same for the water temp ports on the thermostat housing, except 1/4 or 3/8 NPT depending..

-

My Vintage Rallies Texas 1000 Thread

I've hauled a Z or two on a U-haul trailer. None had spooks, but the approach angle seemed pretty low. Jack up the trailer hitch as much as you can to lower the tail. In the worst case, nothing says you can't back it on the trailer! Might be best from the prevent rock spray on the pretty front end point of view. Happy hauling!

-

Innermost Shifter Boot - Any Clamps Holding In Place?

No clamps. There is a lip on the trans that it fits over. Fun to install, an exercise in strong finger manipulation and stretching in an awkward spot.

-

Differences between 2+2 and 2 seater suspension

Chuck is correct. Same same. There is no left and right, same part, just flipped.

-

Brakes slowly lock up after driving 10 miles

Still have the push rod length too long me thinks. Might want to check out this thread on Hybridz. http://forums.hybridz.org/index.php/topic/102754-a-one-inch-diameter-brake-master-cylinder-for-the-s30-z-cars/ It has a section on properly setting the length of the push rod. At the bottom of post #1 is a link that contains an excellent article on the subject. Definitely worth reading. Other than that its the master itself that may be bad.

-

Tired of tuning,tweaking,torqueing,wrenching---JUST DRIVE!

Nice. Now I REALLY want to work all afternoon....

-

Temp sensor wire

http://www.vintageconnections.com/ Click on the "Place an order" link, then scroll down to "section 2". I believe you need their3.8 mm barrel connector part SS2. Get their RTL crimping tool as well. Great qualiy and reasonably priced at $39.

-

Did jay spill the beans?

"got to tour the design studios and maybe take a guess at what the new 240z might look like...." Holy $hit batman!!!

-

Overheating

This requires taking the water pump off, but defintely needs to be checked. The condition of the cavity on the front cover where the pump vanes fit is critical to the pump efficiency. If there is any wear from a previously loose water pump vanes rubbing or cavitation damage to that area (looks like poc marks) the pump is simply not putting out the volume it needs to. Was the cause of my issues some years ago.

-

Electrical issue on 73 240Z Help please

The FSM for a 73 can be found at xenons30.com under the reference link. Haynes diagrams are rarely complete and representative of all teh changes. Every year the electrical changed in a significant way. Looking at the "Body Electrical" document, Page BE-2 that manual has a diagram of all the "stuff" in the engine bay. Sounds like that relay is #18, the Throttle opener relay, Manual trans only. The six wire relay on your other car might be an automatic, ie part #17, seat belt relay. BE-5 has the whole schematic, it looks like the BW wire goes directly to the ignition switch, and as such if the relay of blown, may be cause of your problem. Check all the fuses and the fusible link. Try removing/unplugging the relay and see if that helps. Its not critical to operation. In any event, it can very likely be replaced with a standard Bosch type relay. Its a simple two terminal coil and two terminal switch function. Unfortunately the schematic does not have the wire colors other than the BW and GB so it will take a bit of sleuthing. Good luck Oh and what does it do? Seems a speedo sensor turns on this relay, which accuates a vacuum device which likely opens the "throttle" more.. Don't ask me why... I bet its emmision related.

-

Picked up a granite surface plate tonight.

Excellent sleuthing Blue! You can either spray glue various grades of sand paper to it or use this system of abrasive particles as the lapping media like these http://www.leevalley.com/en/wood/page.aspx?p=33017&cat=1,43072 I wonder just how flat that granite really is?

-

Balance tube

Can't see this as any issue at all. Relocate away.

-

Sparco EVO 2 in an S30? Will it fit?

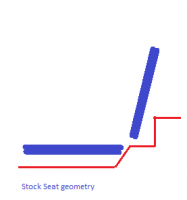

Most" seats will "fit" but will you like the limitations of how it can be mounted? The gross restrictions are the width at the shoulder with a large bolster, that to hit the door, or for a 280, that lump in the trans tunnel for the cat on the drivers side. Other than that, most "go in", but.... Height is a function of the method you select to mount the seat. Lower is better (and harder to accomplish with sliders that work), but what constantly catches people is the ability to move their lovely new seat back far enough once mounted. That 3-4 " riser bump from the floor up to the short flat area behind the seat typically prevents most seats from moving back as far the stockers. The stock seat-backs start high enough off the floor and are positioned back from the end of seat base, so that they can nestle above that bump and allow the seat back to move almost to the luggage riser with the seat base still in the floor area just touching the bump. Most aftermarket seats can't do this as the back and base connect low and at the same point. This traps the seat back AHEAD of the bump and leaves way too little room to the steering wheel and/or pedals for anyone over about 5-10. I'm dealing with this now with some Corbeau's. Not fun. If you mount them high enough to get them back enough, then you're typically much too high for head clearance. Tough call. Carefully inspect the seat back/base joining geometry on your stock seats and compare to what you're putting in before committing. Most aftermarket ones I've seen are all pretty much the same.

-

Clutch goes to floor, not engaging.

Here's hoping these are not remanufactured hydraulics with old problems left inside. Don't forget your copper crush washer on the slave to hose connection! There's one in the box, isn't there? You can always use the old one if need be, shame if its not new.

-

No oil pressure or guage not working?

First ground the connector on the yellow lead that connects to the sender and see if you dash gauge pegs at max pressure. (key in RUN position, engine not running). If it does, then the gauge is fine, sender is suspect. If not, look for electrical stuff. Try the fuses first. Also check wire crimp on the barrel connector for the sender on that yellow wire. May be broke off or just about broke inside the clear boot that you can't see. I see you did the ground thing, points toward gauge power issues. Oil going everywhere with cam cover off means you have some oil pressure. No need to panic yet.

-

rear strut brace

The strut towers on the late 74-78 cars is quite a bit taller (closer to the ceiling) than the earlier ones. Since the struts are angled inward, I'de guess the tops of the struts are a bit closer together, so the 240 rear strut bar may have to be shortened some. May be enough length adjustment in some of the designes to make it work anyway. The seat belt retractor stuff on top sure gets in the way of all this for sure. Always wondered why they changed that strut height. Don't suppose it was the seat belts? To put a retractor style shoulder belt in, they had to move it from its earlier mounting point. Using the top of the shock tower made sense, but it was too low. So they raised it, and had to add that fat insulator on the strut to compensate. That's my guess. Someone needs to measure across of the center of the struts on a 280 and 240 and report the difference.

-

Positive battery terminal keeps turning black?

Weird indeed. Not the norm at all. I can't see battery size being the issue. Something in the atmosphere is electro-plating those terminals. I wondering if the battery doesn't have a leak. Sprinkle a bit of baking soda around the terminal and see if you get any sizzling...

-

My Datsun Spirit L28 Build.

Great point about the manual way to trigger a spark event with paper interrupting the light and sensor. Also don't forget that you take the whole dizzy out of the block and spin the base by hand to test and trigger spark events, you don't have to have the engine cranking or even running to turn it. Keeps things simpler, quicker to test and hopefull stress free! Good luck!

-

Amazing picture...

Notice which one is in front. No surprise!

-

Ignition troubles

Don't discount the ignition switch contacts going bad. The start position often becomes finicky. As a test, hook the +side of the coil directly to the battery + with some spare wire, and jump the starter spade terminal to the positive starter terminal to crank it. See if it starts and runs without dying. This totally bypasses the ign. switch. Worth a shot.

-

No oil pressure. Fresh engine. Ideas?

Diseazed, ya, I'll check that cam plug too, but I think its good. Thanks for the quick response. I guess I'm at the age that I need a check list rather than relying on my memory for stuff like this. Tough to admit. That's life.... Jim

-

No oil pressure. Fresh engine. Ideas?

Well thanks to you-all I have the solution. Just your virtual presence was enough. Actually I just had to write that out to get my thoughts in order. There are two oil gallery plugs, one in the back (I put that one in), and one in the front; which I didn't put back in.... Funny how that causes a short circuit for the oil pump right back to the pan. Easy enough to fix. I'll pretend I'm happy that it was the front one and not the back...... Much messier. And now we also get to find out just how good that Lubri-plate engine break in stuff is that I used....

-

No oil pressure. Fresh engine. Ideas?

Gang: Time to call on the engine building experts Finally got to the stage of starting the L28 in a very long term restoration project today. 71 240. Well it runs great, but with just about no oil pressure. oh god, what have i done.... So, the facts: Engine Fresh rebuild, top and bottom. Fresh everything. Including new oil pump. L28 flat tops, F54 block. E31 head, larger valves, stage 3'ish cam, nothing radical. Engine was assembled on stand 15 months ago, and oil pump run with drill and shaft to confirm prime and oil to the head. Everything is great. Engine put in car, but never started until today. Problem: Runs great, but oil pressure on stock gauge was observed just above 0. Changed sender. Same thing. Screwed mechanical gauge in engine port. Same.... Barely moves if at all. Think.. What did you do idiot... Change out new oil pump for used oil pump. Same problem. Oil pump full of oil when removed. It is primed. Remove cam cover, remove dizzy drive and use drill with shaft into oil pump. CCW rotation, 400 rpm drill. Cam is seeing oil at all holes (internal oiled cam, towers have block off plates), but its just dribbling out of the holes. Pump is turning real easy... Oil filter is full. oil dribbles out of engine port when I remove the sender or mech. gauge. Did compression test, 150 psi across the board. Engine ran all of 5 minutes initially before decided to shut it off due to the oil pressure. Block history. F54 block was taken from junkyard zx to machine shop (7+ years ago). Everything was bad. Crank crooked, bores crooked. All was fixed, bored 040 I think, new pistons, rings, crank turned down some, rods sized, undersized bearings supplied. Everything sat disassembled waiting for a car to put it in. I assembled engine 15 months ago for this project car. Checked ring gaps, and a couple of bearing main and rod clearances with plasti-gauge. What I checked looked great. No I didn't check all the bearings, maybe I should have... My bad. So, other than the first thing that comes to mind, like HUGE bearing clearances, what other stuff may I have forgotten that would cause this type of issue? Ideas please!

-

Removing those last bits of old gasket

Spray glue some 120 grit sandpaper to a flat wooden stick, about 3/4" square by about 8 inch long. Use this to remove the gasket material and to keep the surfaces flat as you do it. Do each section between the alignment pins. Only use sandpaper for the last very thin bits, use a single edge razor blade for the rest. Aluminum nicks easy. Go slow. Patience grasshopper.

Subscriber

Subscriber