I was able to install the quarter windows this past weekend.

I don't have quite enough door gap yet on the left side (last pic). I will let the weather strip that goes between the quarter window and the body compress a bit over a few days, and then attempt again to push it back a bit more away from the door frame. These windows can be difficult to install. I find the best way to do it is to angle the back part of the window out from the fully seated position, and secure the window with the two front screws first. Angling the back of the window out allows a bit more rearward movement. Once the two front screws are in, tighten them to snug while pushing the window back as far as it will go. You may have to push back pretty hard just to get the front bolts to align and thread.

After snugging the fronts, push the back of the window inwards and thread the back two bolts in. Then snug those. If still too close to the door, wait a day or two and then loosen the screws, push the quarter window back further and retighten the screws.

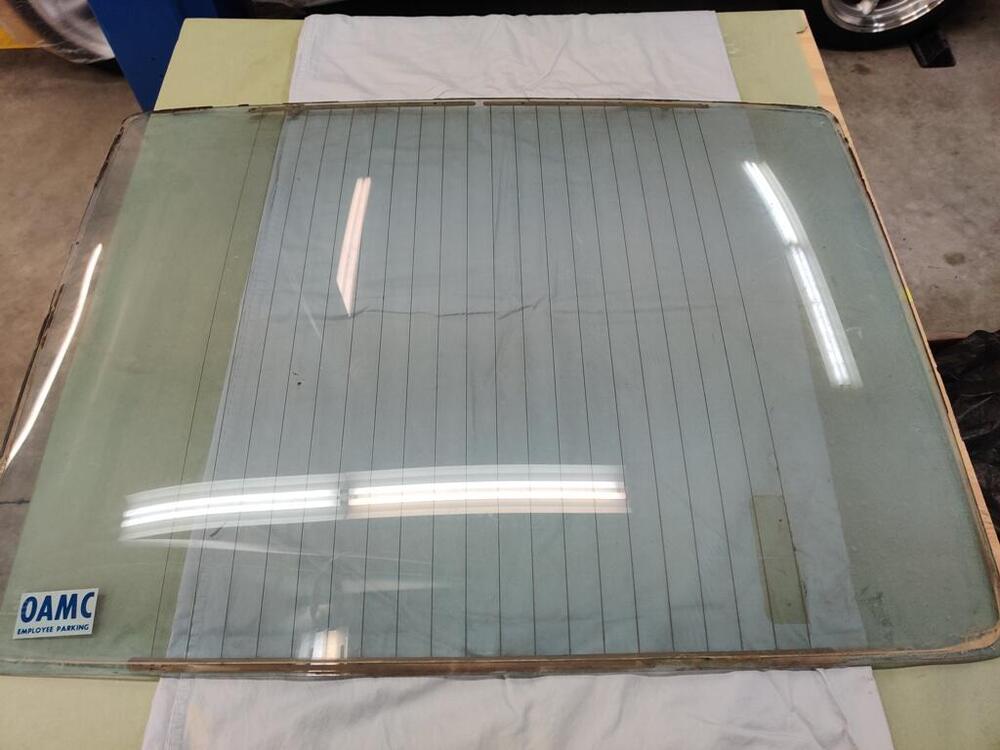

After I put these in, I shifted over to the rear hatch glass.

I actually started cleaning up the wrong one at first. It was a spare that came with the car when I bought it. But, the etching showed July of 71, so I switched to the correct one, which shows May of 1971 (dot above P in TEMPERLITE (month) and S in ASAHI - year.

A couple of tips for cleaning windows... Using a window scraper and fresh razor blades is very helpful to get the glass clean of dirt and grime. It will not scratch the glass not matter how aggressive you are with it. I find a razor blade is very effective for removing "rain spots" or other stuck on "hazing" from dried water. You may have to go over it many times, but it is pretty amazing how effective it is. For final cleaning of "hard water deposits" #0000 steel wool is the ticket. Again, the steel wool will not scratch the glass, and it is necessary to remove the final remains of hard water spots. Also, when you are trying to get the inside of the hatch glass that clean, you can't use a razor blade and scraper unless you want to gamble with damaging the defroster lines. Again, using the steel wool, you can go directly over the filaments. It does a great job of getting stuck on crude that cleaning does not remove.

Finally, I wrestled with installing the rear hatch weather strip. I did not expect it to be so difficult, but after about an hour I was able to get it on, but was a bit worn out from the effort. 😁

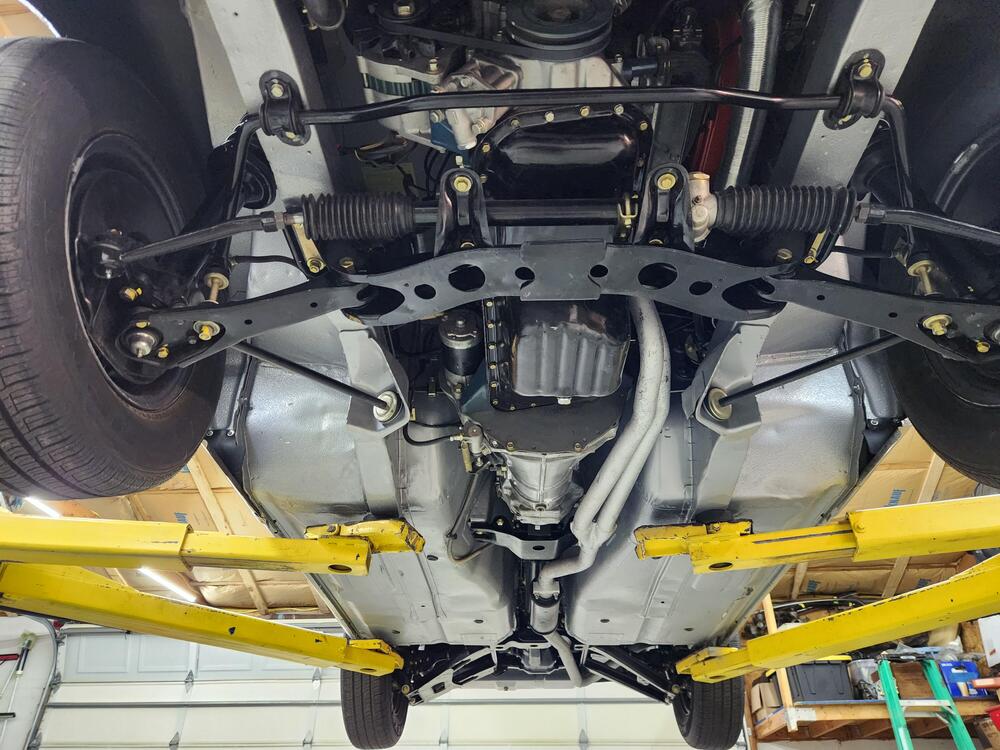

I also made some notable progress with the issues I have been having with the differential. I am looking forward to getting that done, so I can install it and all the things that are being held up by it.

Subscriber

Subscriber 6Points1,282Posts

6Points1,282Posts Subscriber

Subscriber 4Points11,142Posts

4Points11,142Posts