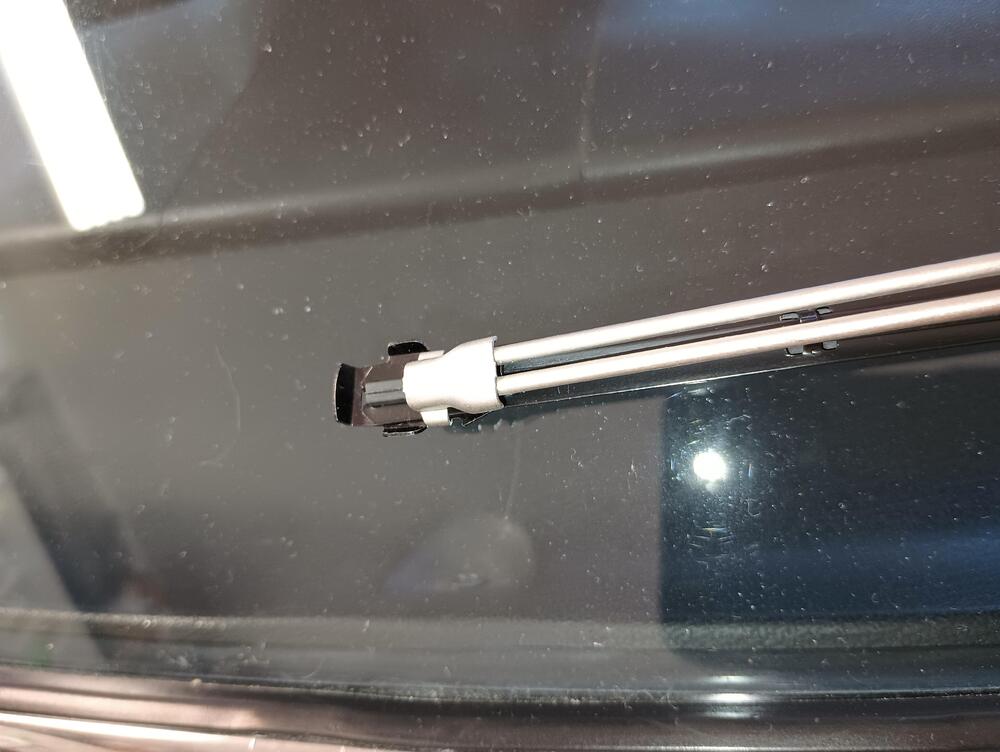

Here's a photo that I took when I was getting my hatch vents ready for installation. Self-explanatory, I hope...

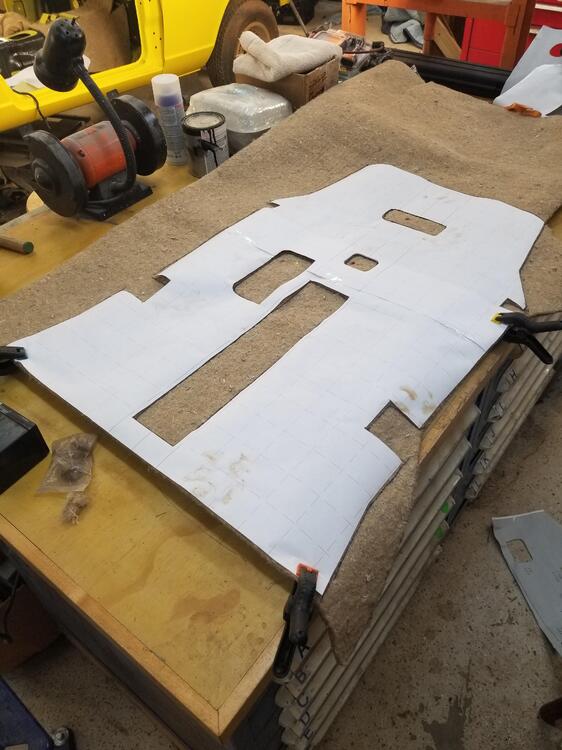

The factory gasketing for the plastic vent plenums was pooched, so I made replacements from soft, closed-cell foam (it's actually foam strip used for sill walls during building construction). You need to use something that's pretty compliant, because you'll need a lot of 'squishability' (technical term) to be able to push the clip into place...

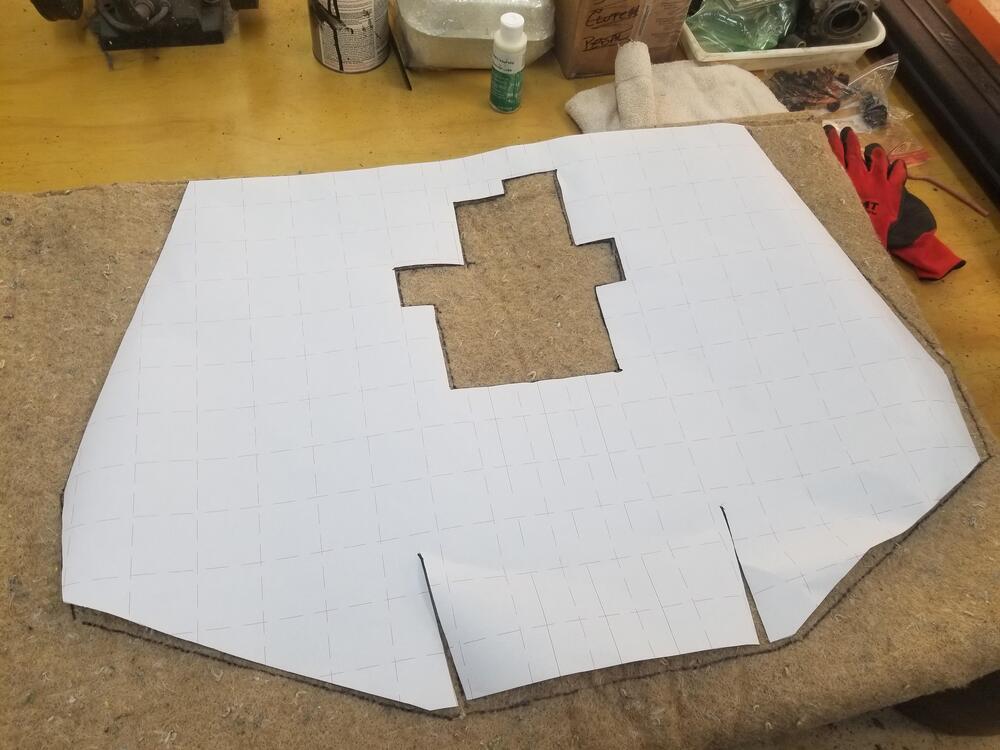

I used the same foam to create a new gasket for the interior trim panel...

During final installation, I used strips of wiring loom tape (non-adhesive) overlaid by a hotel key card to protect the paint as I was sliding the clip into place. The key card is pulled free after the clip is in place. Then the tape is pulled away (the section of tape immediately under the clip can be left in place -- no one will see it and the plastic push-pin will penetrate easily when the chrome vent is pressed in place...

Subscriber

Subscriber 9Points11,142Posts

9Points11,142Posts