The AFR numbers look good. I'm no engine tuner, but I don't think 10-11 at WOT is that bad. Maybe a tad rich, but you usually want it rich at WOT, don't you?

As for the resistance measurements, most of them look good. The two where you are sticking the probes into an empty injector socket (to measure back into the harness) really don't tell you much though. You're just reading a combination of ballast resistors and injector resistances in series parallel combination. Didn't hurt anything, but really no good data to be gleaned from that.

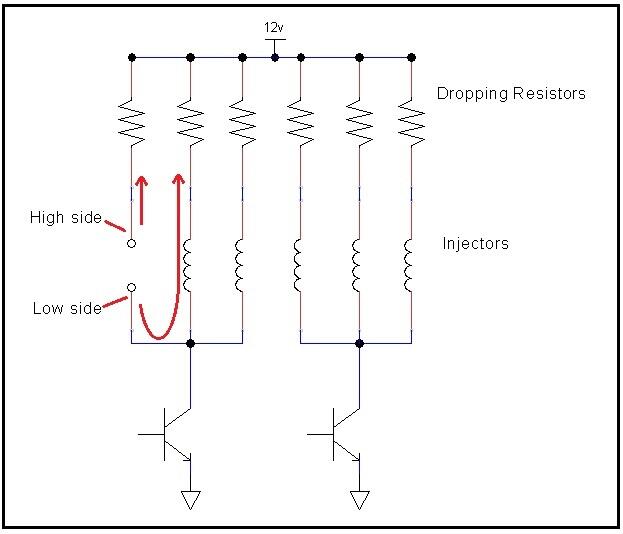

If you're not sure what I mean... here's a pic that highlights the situation. You're just measuring a couple injectors and their dropping resistors in parallel, etc.

In theory, if you're measuring back into the harness with the key off, you should read open circuit. But you would have to disconnect all the injectors (or at least the correct three) to see that. if you crank the meter up to the 2 MegOhm range. you might be able to pick up the leakage current through one of the output transistors in the ECU, but that's about it.

So for the rest of the resistance measurements... You measured the ballast resistors at 5 Ohms and the injectors at 15.5 Ohms. Those measurements look great. Let me think about those numbers a little.

In the end, if your AFR's are good, all that theory by the Volvo folks doesn't really matter. Might be applicable, might not. But your AFR's are on target, so who's to say there's a problem?

Subscriber

Subscriber 4Points1,935Posts

4Points1,935Posts