I ran into another issue with getting the engine and transmission in the car last week. None of the clutch throw out bearing collars in my possession were the one I need for this 240z clutch kit. So, I ordered a new one and I am waiting for that to arrive.

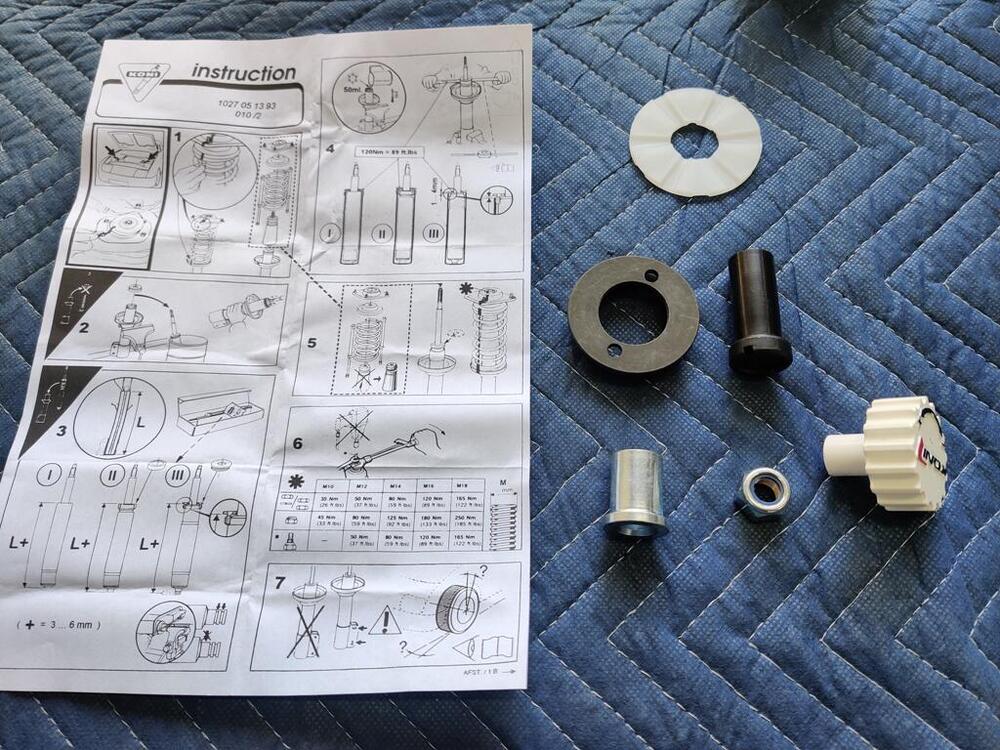

So, yesterday, I switched over to suspension assembly. I bought the new Yellow Koni's for this car (see the linked thread below). The instructions... do not have any words. Manufacturers save on writing and translating when they do this, but I don't like it. It is not clear to me, in some pictures, what they are communicating.

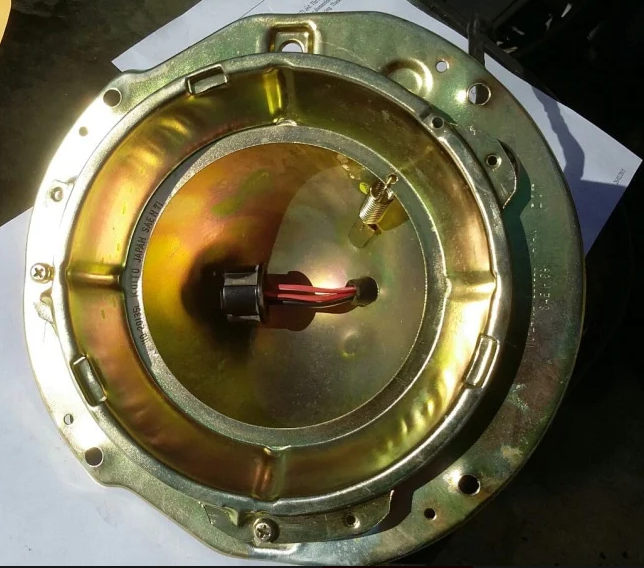

I was surprised to see that the "gland" nuts supplied with the Koni's do not have flats on the sides - they only have two holes in them. I have never encountered gland nuts like this before. I wasn't considering this, and got stuck with having to spend a good bit of time making a tool to deal with these. Essentially, I had to take a thick washer, drill corresponding holes in it, run bolts through the holes, weld those in place and then attach 1 x 1 bar to opposite sides of the washer.

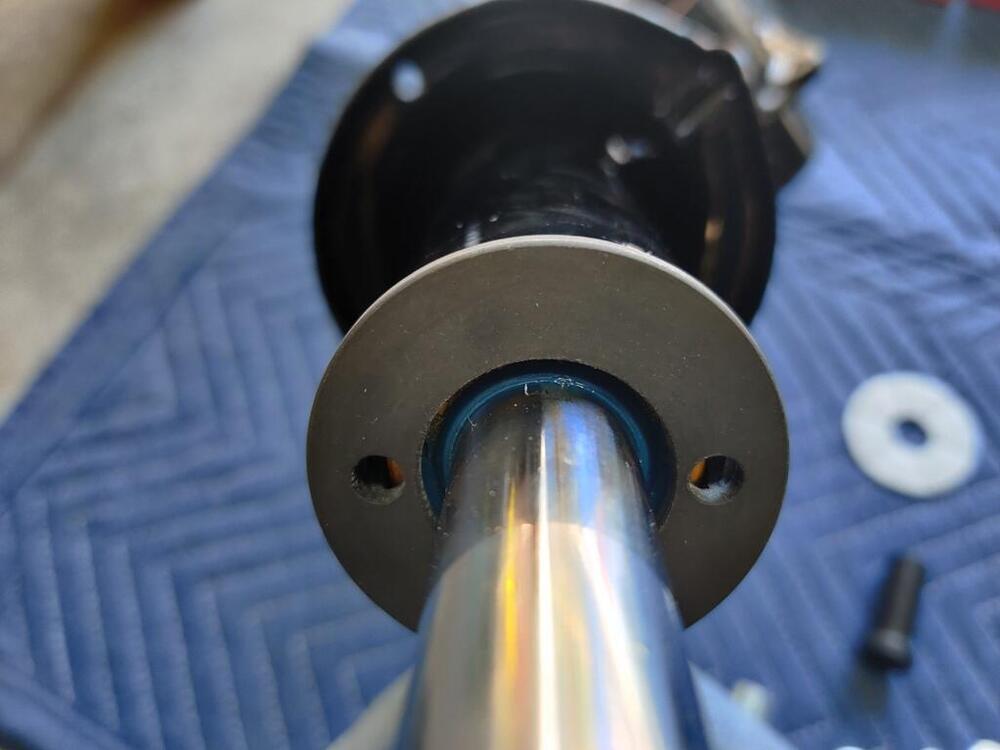

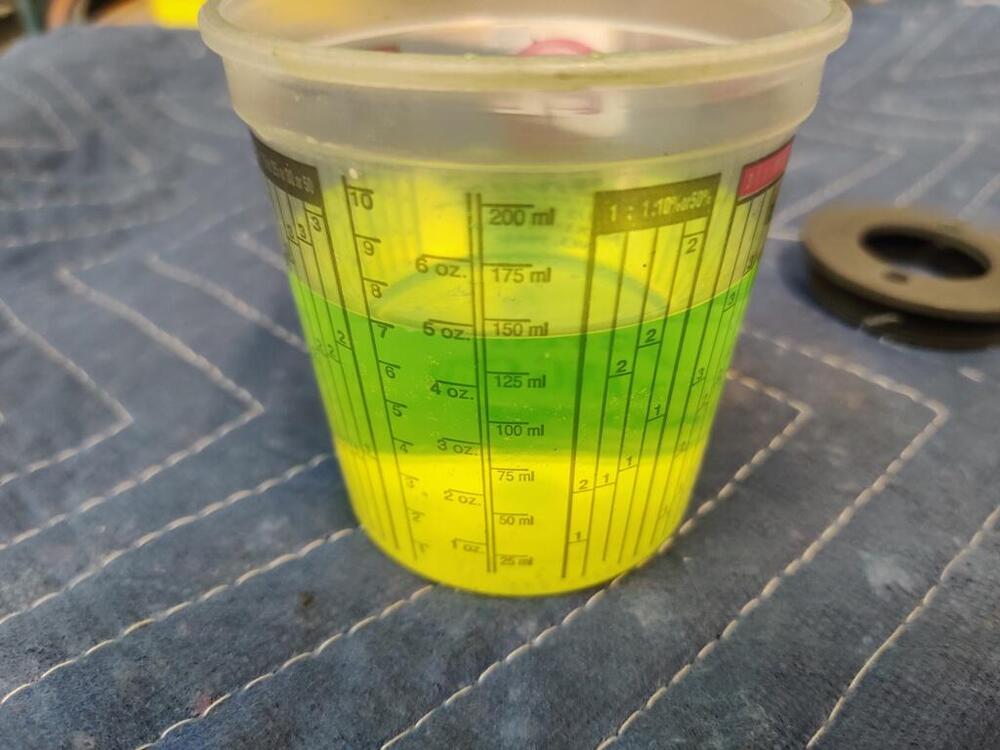

I started with the rear struts. Each one calls for 50 ml of non-freezing liquid. I used a 50/50 mix of distilled water and antifreeze. I think this helps with heat transfer from the Koni insert to the outer strut tube. I used two layers of masking tape around the shaft as a precaution to keep from scratching the strut shaft with the tool. After installation of the gland nut, the distance between the top of the strut and bottom edge of gland nut were just under the 1-4 mm specification.

Switching over to the front struts, I ran into the issue that others have in the following thread. The insides of my front struts are clean and show no signs of any rust. However the gland nuts would only engage for essentially one turn of thread engagement. In the links below, you can get more context if you wish. I have contacted Motorsport Auto by email and asked about receiving modified gland nuts to fix my issue, as they did for Jim Arnett - @jfa.series1:

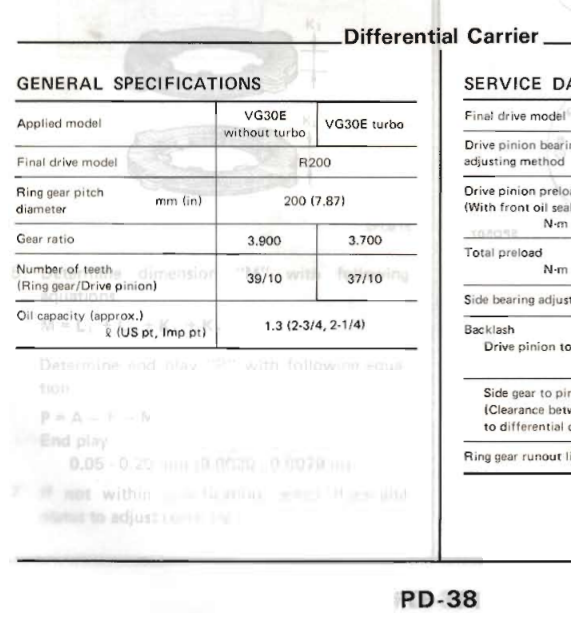

So, a spacer/shim I think will be needed to assemble the differential is on national backorder with no ETA. No progress can be made on the differential. I am waiting for a throw out bearing collar to arrive. No progress can be made with putting the engine and transmission in the car. I am waiting to see if Motorsport auto can send me modified gland nuts. No progress can be made with assembly of the front struts, but I can continue with the rear struts.

Today, I will pivot to the steering rack. Perhaps I can make progress there, and with further assembly of the rear struts.

Subscriber

Subscriber 6Points11,142Posts

6Points11,142Posts

.JPG.f69d862fbbca8aaa6701ac477bb32750.jpeg.jpg.96483467ffb87d58fb9788ed8f04a064.jpg)