I thought of another mis-fire problem and the solution. Like Mark, it was related to the plugs.

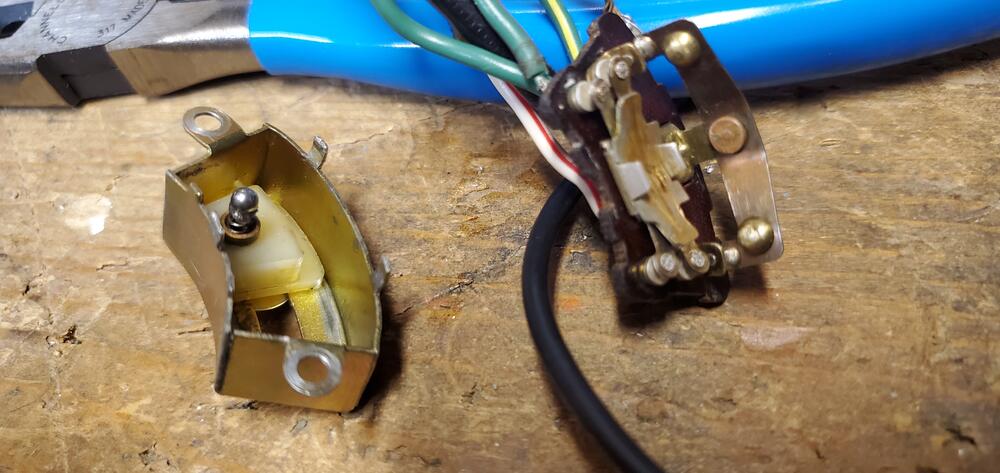

I used, and still use, NGK BPR6ES plugs. The issue I routinely run into with them, is that the end of the plug where wire snaps on, is threaded on to the plug, and is often loose.

Several years ago (2015), a random issue with mis-fire throughout the range dogged me for a year or better, and when I finally discovered that one of the end caps was loose on a couple of plugs. Tightened them up, and the mis-fire went away.

The BPR6ES-11 plugs that also spec'ed for 280's with EFI, don't have the threaded end cap.

I described this WAY back in 2015. The thread lionk is below if you want to see pics.

EDIT EDIT : just doing a bit of a good search. NGK plugs BPR6ES #7131 have the threaded caps, #4008 have solid caps! Jim, stop buying #7131 BPR6ES plugs you old idiot!

BTW, Don’t order the Denso #4008 plugs by mistake. They are NOT the same….. Just saying…..

Subscriber

Subscriber 7Points1,282Posts

7Points1,282Posts Subscriber

Subscriber 3Points11,142Posts

3Points11,142Posts