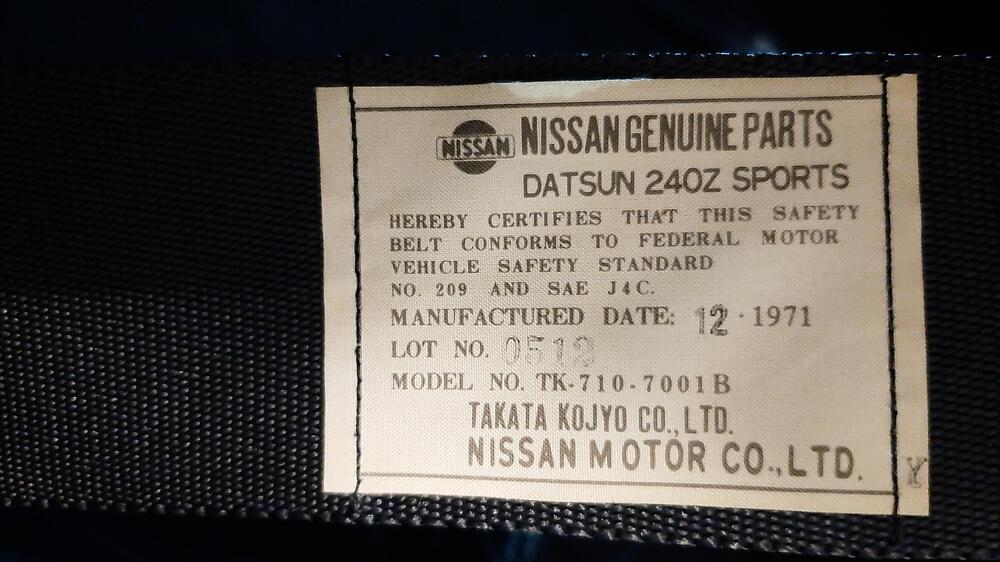

I couldn't find a thread on this subject, so I started one. For the future reference of others who, like me, live in a area where obscure metric bolts and taps are difficult to find, the bolts for the seat belts on a 1971 240Z are a rather unusual size. They are M11 x 1.25. Some of the bolt holes had some dammaged threads. Bolts would go in just a little hard, but when they came back out the threads were rounded off. I tried the old trick of trying to clean the threads with a bolt by cutting a grove in the threads to make it look like a tap, but it didn't work. So I searched for most of the day for a local (Within a 50 mile radius) supplier of a tap in the size mentioned, without success. Finally my Mechanical Engineer son asked if there was an S.A.E. equivalent... silly question I thought until I did the math. 7/16" = 11.1mm 20 threads/inch = 1.27mm/thread I found some SAE 7/16 x 20 bolts and nuts in my assortment of random bolts, and to my suprise the M11 X 1.25 bolt threads into a 7/16 x 20 nut perfectly. You would never know they are different. I bought a tap for the SAE size at the local auto parts (Napa) store. The metric bolts threaded in and tightened up perfectly.