Played with the eFan. No way it's gonna work. I can't get clearance no matter what. I don't want to use an aftermarket eFan, they just don't have the pull of the Bosch units.

So, I trimmed the Volvo (Aisin) fan to fit the Nissan clutch

I trimmed the top half of a Volvo standard shroud to fit, I don't like the fan blade exposed. Riveted brackets to either side of the rad vertical plates to retain it ( I used 3M Velcro to hold it while I figure those out)

While I was in there, I fixed the distributor vacuum line/tee connection to the TB and charcoal cannister

The distributor wiring had been nicked at some point by the fan, so I re-routed that, and added a sealed 2 pole timer connection where the wire was damaged (no pic)

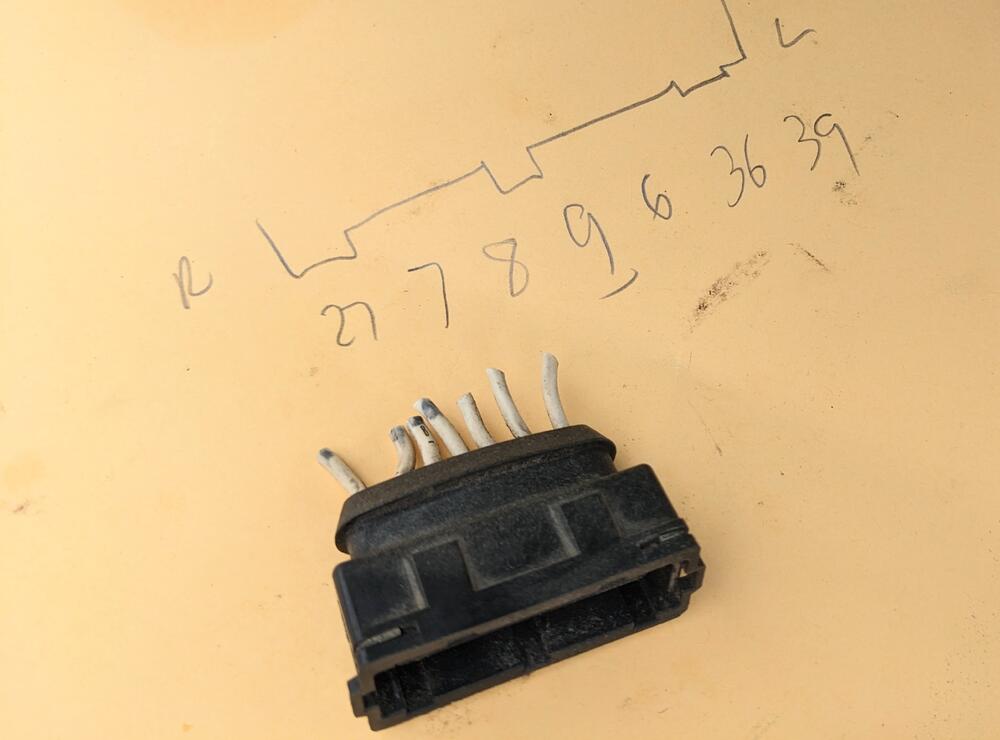

Rewired the AFM also - blurry pic. The heat sheath below is on the dist wiring - since it is now closer to the manifold.

.thumb.jpg.074fe9b6bf35c9bc9a3345d6b7a0aced.jpg)

.thumb.jpg.f7ef53fae9a5baa566e2251adbc7e690.jpg)