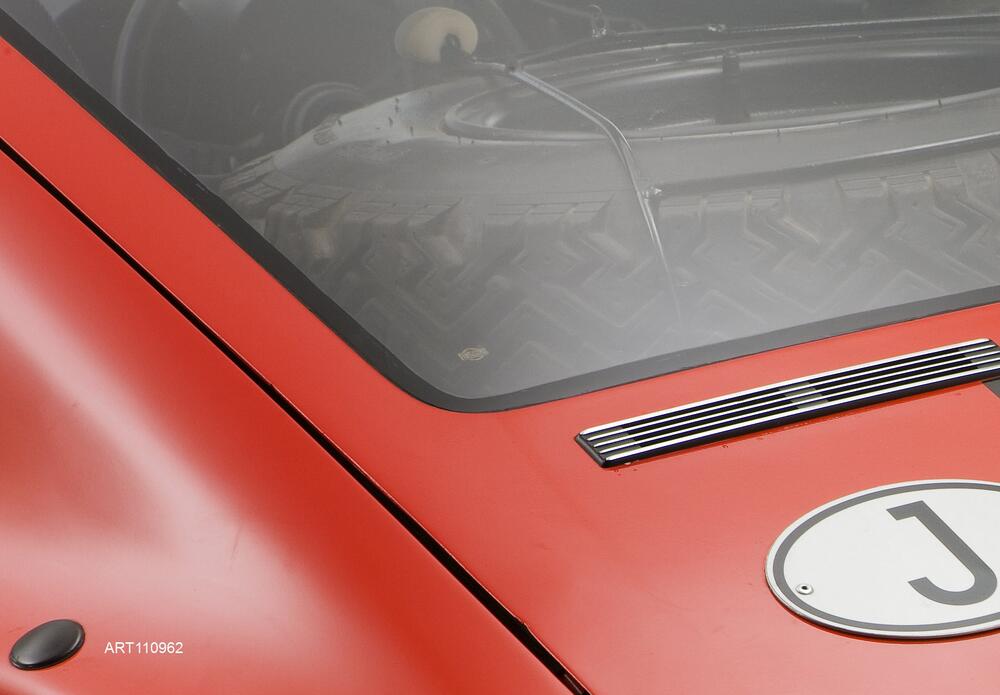

Yes, pictured - not very well stamped, I'm afraid. Tailgate permutations for Z432-Rs over the production life of the S30 are a slight mystery to me, so I'll invite others to chime in with info. From the parts manual, a Z432-R with lightweight decklid would have a fiberglass frame, an acrylic window a little thinner than a stock piece of glass, and a standard rubber gasket to affix it into the frame. The Lightweight Spec Works cars did it differently - they used an even thinner piece of acrylic (perhaps half as thick, by my estimates), bonded directly onto a lip on the decklid frame, without using a gasket (refer to picture)- essentially making the frame/acrylic a single piece. This feature is visible on pretty much all the 1970-71 period photographs I have of the Works cars, so I have come to believe it's the likely procedure the Works team used on all the Lightweight Spec cars. The acrylic is so thin, that there's really no way it would be rigid enough to stay in place using just a gasket. In addition, I'm not sure that this exaggerated mounting lip on the frame was a part of the standard PZR frame - it's possible that this batch of decklid frames were modified specifically to allow for the two pieces to be bonded together. I just don't know the answers yet - more research is required.

The above is all a bit geeky, so I apologize for deep-diving into the minutia. Unfortunately, my acrylic was ruined by a former owner, who cut a 6" hole for what appears to be a fresh-air venting system. Thankfully, I have a "very used" standard PZR acrylic window. So, in order to fix my existing decklid, I'm going to have to cut off the old acrylic, and bond on the new, thicker one, or bite the bullet and replicate the existing acrylic piece using thinner material. Right now, I'm leaning towards the latter, for consistency.