I Have installed a few windows in British cars and this is my second opportunity with a 240Z. So, I don’t have a tremendous amount of experience, but I think this will provide a bit more detail that may help you. Outlined below is a procedure that worked well for me and I hope will help you. Please feel free to correct/improve the process for the next guy.

Door Glass Install

Install the outside rear view mirror.

I installed insulation and sound deadener. I think this helps with noise and temperature control and it also gives the door a bit of added weight improving the feel of the door.

I put white lithium grease on the rollers and channels, and on just about anything else that moved before installing anything.

I installed the door locking mechanism, and all of its associated parts exterior door handle, key lock, and interior door handle.

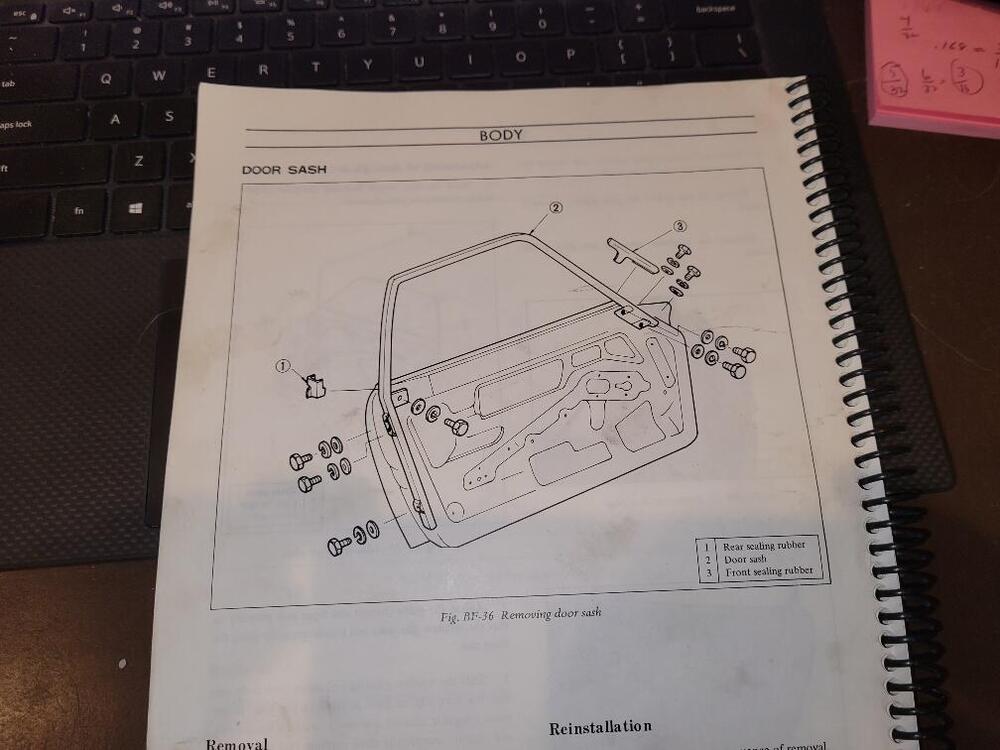

I removed the door sash (frame/channel that surrounds the glass) to make it easier.

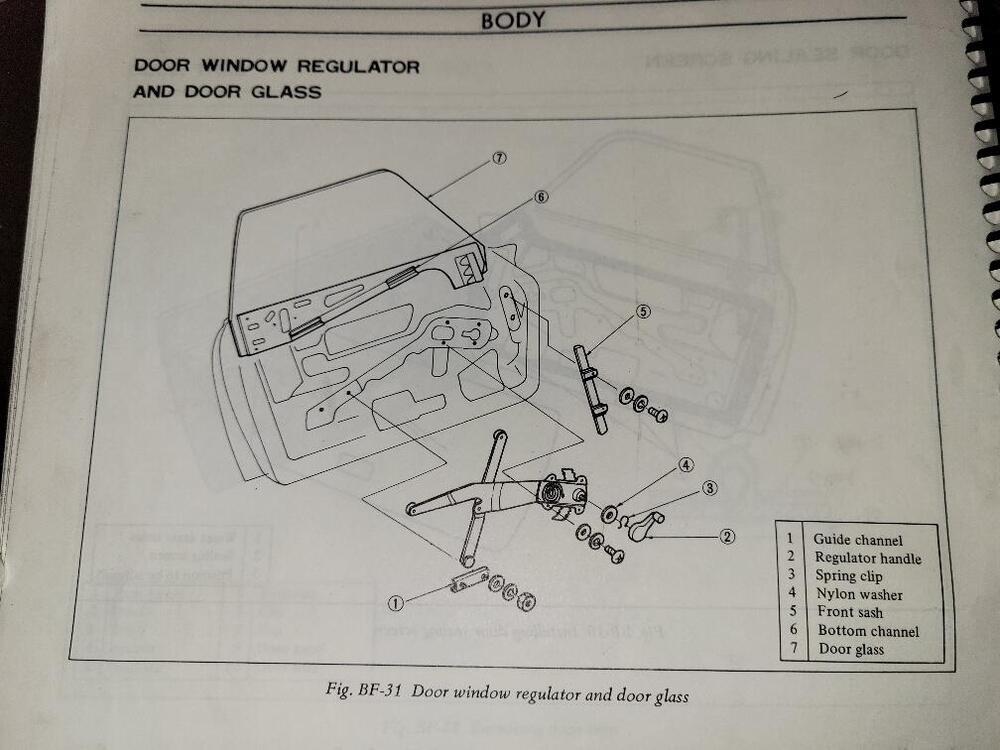

I installed the window regulator. To move the regulator I attached a vise grip to the knurled winder mechanism, be careful not to crush the grooves.

At this point my troubles began. From what I read I thought that the front sash (front channel about 12 inches long) and the guide channel were supposed to be installed. I tried installing the glass by reversing what the service manual describes for removing the glass. Tilting it and sliding the front roller into its channel. I wasted hours and lost ½ a pint of blood and got nowhere. When the front roller was in the channel it would come out as I tried to install the rear roller, or the front sash guide. So, I walked away had a cup of coffee and decided to take a look at the entire mechanism. I was alone on this task so it is easy to get worn out hunched, and holding the glass, etc. Here is what I came up with and the glass was installed in less than 30 minutes.

The first (6) six steps are valid and was my starting point. The front sash (approximately 12 inch long channel for the plastic slide at the front of the glass) and the guide channel (approximately 4 inch channel mid door toward the door lock) are not installed at this point.

I think this would be a good time to remind you that you should install the outside rear view window before going any further. It’s painful to do it after installing the glass, don’t ask how I know that it is painful.

Getting the window into the car can be tricky. The manual suggests: front first and down on an angle. If you are concerned about your paint I would protect it with at least a strip of tape on all edges of the door. Watch the outside of the window as it enters the door as there are screws (at the front tip of the window where the slide is located), that can get hung up on the door. The window sits closest to the door skin, in between the skin and the window regulator.

At this point I re-installed the window sash with one screw in each or the two top corners.

There are 3 rollers. Two of the rollers face the window. One faces the interior of the car. One of the two rollers that face the window will be on your left as you face the interior of the door. The 2nd roller will be on your right. The right most roller is mounted on an arm that has the third roller (facing the interior of the car) attached at the opposite end of the arm. This roller (facing the interior of the car) should be sitting down, toward the bottom of the door, before you try to install either of the other rollers. If it is not in this position it will be more difficult to position it later on because it will get hung up on the regulator and the interior door sheet metal.

Seating the regulator rollers into the window channel

Wind the regulator almost all the way down.

Now slowly wind the regulator up and watch the rear channel, toward the door lock. I believe this step is easier if this roller enters the channel from the right side (nearest to the door hinge) of the channel. When it is close to the regulator roller slide the glass forward or back to allow the roller to enter the channel. Once the roller is in place slide the glass a bit more to insure that the roller stays in the channel.

Slowly wind the regulator almost to the bottom of the door. I believe this step is easier if this 2nd roller enters its channel from the left side of the channel, nearest the door lock. Remember the third roller must be lower than the other two rollers. Watch the front channel of the glass. When it is close to the level of the regulator front roller stop and move the glass forward toward the door hinge, make sure you don’t move the glass so much that the first roller comes out of its channel. Push the roller into the channel and slide the glass toward the rear (toward the door lock) to keep the roller in the channel. To move the roller toward the channel you might try pushing down on the opposite side of the arm where the 3rd roller is located. You might also need to grab the glass and move it forward (toward the door hinge) corner up toward the top of the door.

Slowly wind the regulator up about half way, when the remaining roller is accessible slide the guide channel on to the roller. Move the guide channel toward its mounting holes to get the guide studs in position. You may need to wind the regulator up or down slightly to get the guide channel studs to their mounting holes in the door. When one is in the hole place a nut on it to insure that it stays put. By winding the window up/down you should be able to manipulate the guide channel’s 2nd stud into its mounting hole.

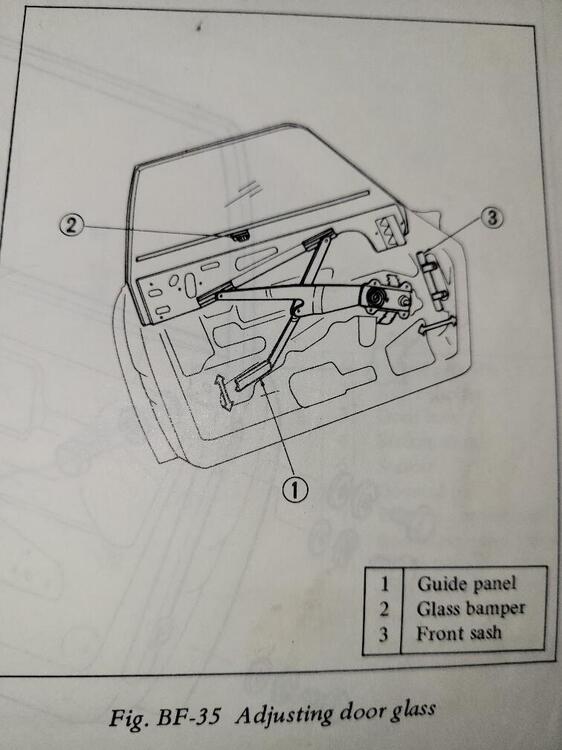

Now from the top (right side facing the door interior) push the front sash down and guide it onto the plastic window slide. Push it down and move the window to the front or rear so you can place the screws through the door and into the front sash.

Tighten (finger tight) everything and using the window regulator roll the window up and down. If everything is moving smoothly then tighten everything and bandage any wounds.

Subscriber

Subscriber 2Points11,142Posts

2Points11,142Posts