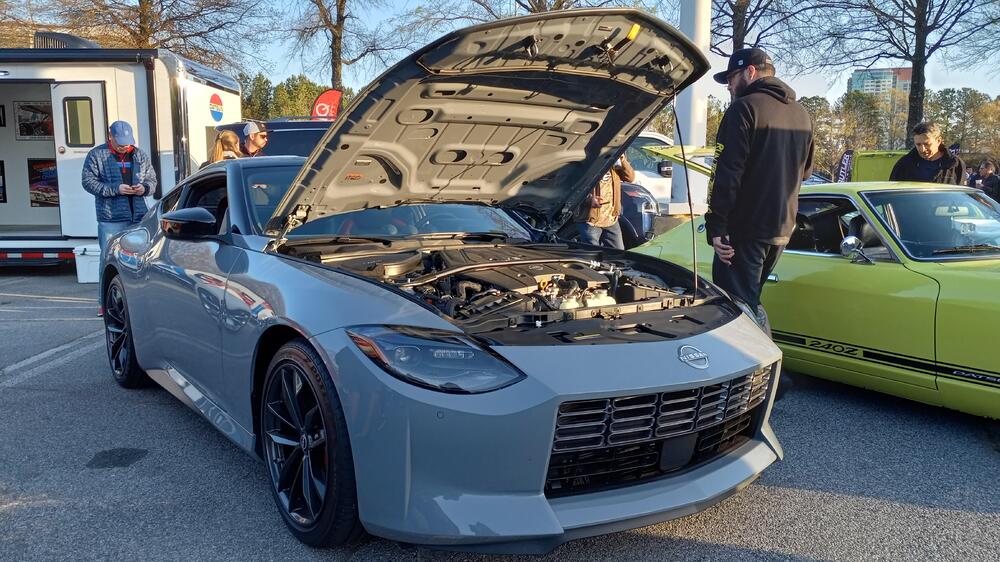

I forgot to post an update to my Z since the head fiasco! I was able to get the new gasket installed and torqued all studs/nuts appropriately. I chased my threads and a few had some gunk so it was a worth while job. Zero smoking since! I was so relieved. I did some more research on other platforms and it seems like it is a common issue on the ARP head studs. I assume it is a combination of user error with some dirty threads and what not.

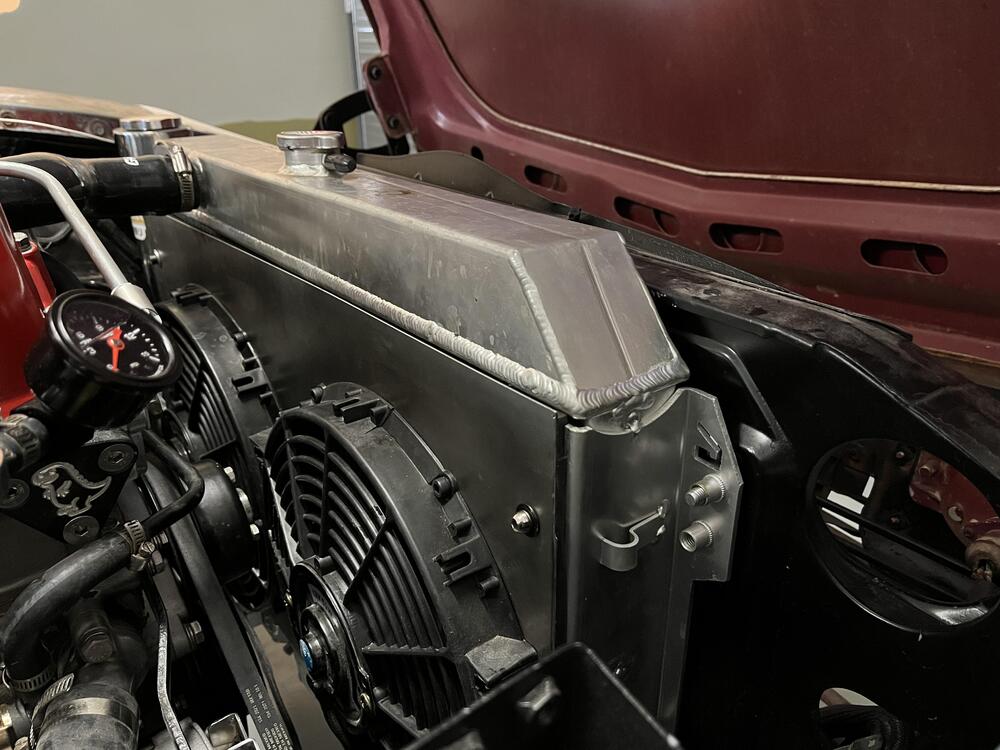

Regardless, times are good and I have been able to finally take the car out for a spin longer than 1 minute! I was having some high temp readings with my radiator setup. Nothing too crazy, but sitting towards the M on my TEMP gauge. Since I am running no shroud, I did a quick DIY with some left over aluminum and foam to get a seal. I am now always running right in the middle temp. I also grabbed a generic overflow container and just waiting for the line to show up in the mail.

Other than that I have been busy working on some new bumper plates and other misc. fill plates. I originally used a snap in design but the tolerances were so tight that I would occasionally run into broken clips or a loose fit. I switched up the design to be a two piece clamp style. This will give me room for any variances in peoples bumpers while still providing a nice solid mount. My goal for this design was to provide a bolt in solution. I know many people don't have access to a welder or don't want to sand their paint, weld, repaint. While this doesn't provide as flush and clean of a look, it is still better than a gapping hole in my opinion. These are sandable, paintable, and wont warp due to heat. Here is an example for the small bumper holes, but I have created plates for all the rear bumper ones, even the awkward side bumper mount holes, as well as for the side indicators. I hope to start selling these soon!

Up next is tackling the bushings and suspension. I am looking to see what people think of my setup:

Koni Yellows from MSA with Eibach Springs. I am hoping I will have a level look when running no bumpers, I read alot about this issue but it is hard to find an exact replication. All of my isolators are shot so now is a good time to run 240z style all around if it will help with leveling the car. I am also considering Vogtland springs.

Wheels I am torn on 15x7 with 225/50r15 or to run a 205/50r15. Smaller tire will be lighter and easier steering but I do like the meatier look of the 225's.

Full Energy Poly Bushings. But I will run the softer TC rod bushings on the backside. TechnoVersions Diff mount as well.

Subscriber

Subscriber 1Points11,142Posts

1Points11,142Posts