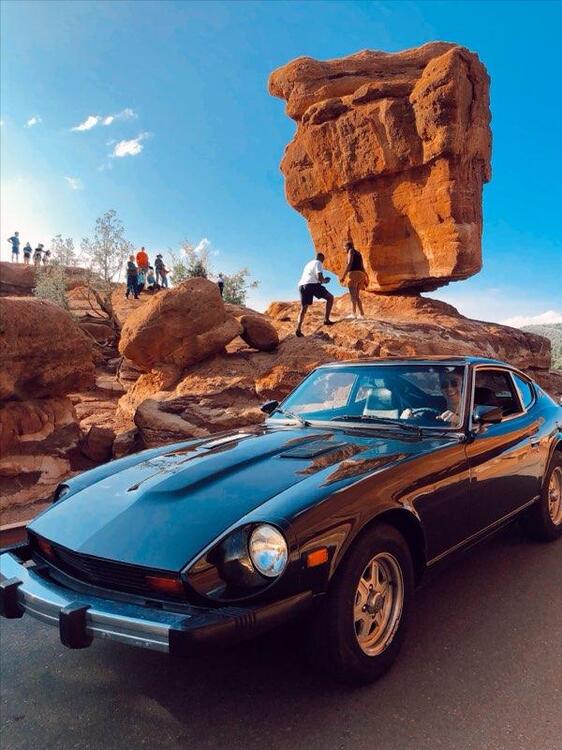

I came across an IG post that caught my eye in which a fellow 280Z owner had LED lighting behind the Z emblems rearward of the quarter windows. Turns out a garage in Las Vegas that does a lot of Datsun work (Harmon Restoration) had done the work for him and would sell a kit with an amber LED bulb for each side which included all wiring with proper Datsun plug connectors for a seamless installation onto the rear lights harnesses. Since I love LEDs and this looked like a novel idea I ordered one such kit which I received a couple of weeks later. Their original kit was meant to work as an auxiliary turn signal light but I didn't like that idea, doubting it's legality and usefulness. I asked them to wire my connectors so they would work in conjunction with the parking lights, which they did.

First I checked the lights by plugging them into both tail light harnesses (all good), then I loosened the interior plastic panels so I could run the new wire harnesses forward.

After prying the Z emblems off, I carefully drilled 5/8" holes at the center of the vent holes and a second steel panel immediately behind it. I lightly sanded and repainted (satin black) the vent holes making sure the raw metal edges were covered inside and out.

After applying a generous quantity of black silicone sealant around the light stalk, I installed it from outside and secured it with the included nut from inside the cabin.

I finally put my interior panels back in place and reinstalled the Z emblems.

When I tested the installed light the LED was way too bright, even brighter than the parking lights, and the glaring bulb was very visible in many angles! Not what I had hoped for at all!

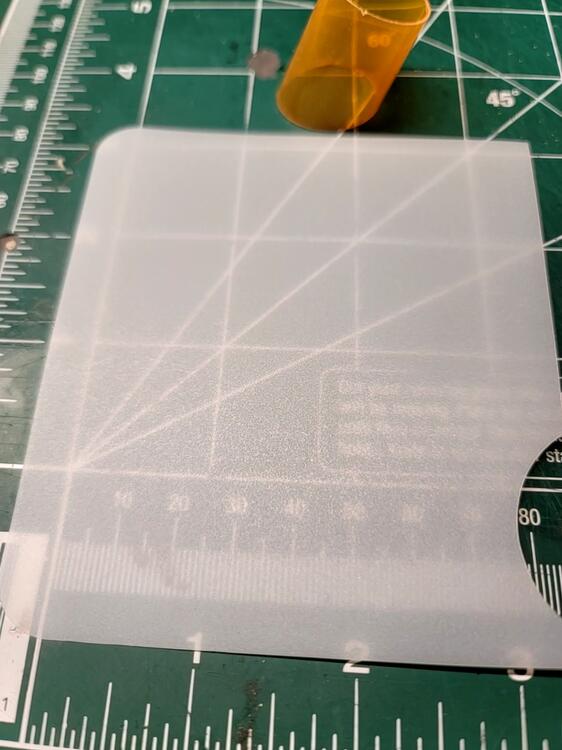

After some thought I came up with 2 light diffuser ideas. The first was a simple circle of "frosted" .5mm thick white plastic glued to the back of the emblem. It looked great when illuminated (although still too bright for me) but the white plastic was plainly visible when the light was off. Additionally, this option may have obstructed the air exiting the cabin to a certain degree.

My final option was to construct a cylindrical "diffuser" which would hide the LED, direct light to the back of the emblem, reduce the intensity of the light, not obstruct airflow, and be pretty much invisible when the lights were off during daylight. I used a 3/4" amber translucent plastic tube (small prescription container), cut out to the correct length and angle.

I then introduced a piece of the frosted white plastic inside the cylinder to diffuse the light, but covered 2/3 of the inside of this plastic with black duct tape allowing light to exit only at the end immediately behind the Z emblem.

Lastly, I covered the outside of the tube with a layer of mirrored tinted window film so it would allow light to exit but reflect the black paint from the vent holes on the outside, rendering it close to invisible once installed. The diffuser was then hotglued to the back of the Z emblem and reinstalled on the car.

It worked as intended and I now have subtle amber indirect illumination behind the Z vent emblems that don't telegraph any alterations during daylight or when the lights are off.

I realize this isn't orthodox at all but I really like the cool factor on my restomodded 280Z.

Sent from my SM-N986U using Tapatalk

Subscriber

Subscriber 4Points27Posts

4Points27Posts